Pollutant combined removal device and method through recycling of chlorine in coal

A combined removal and chlorine element technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of aggravating PM2.5 condensable particle emissions, PM2.5 removal difficulties, downstream flue and equipment Corrosion and other problems, achieve the effect of realizing the utilization of waste resources, solving the increase of SO3 emission, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

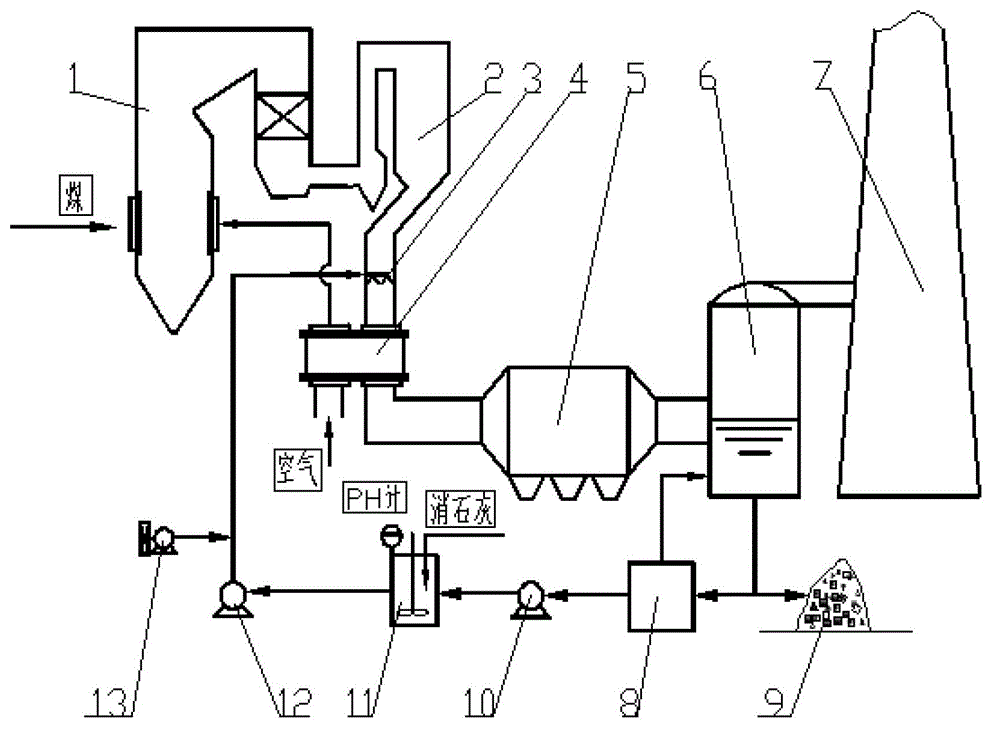

[0028] A device for recycling chlorine elements in coal to realize joint removal of pollutants, combined with figure 2 , including a boiler 1, an SCR denitration device 2, an air preheater 4, a dust collector 5, a desulfurization tower 6, a chimney 7, and a slurry pump II 12, the boiler 1 is connected to the SCR denitration device 2, and the SCR denitration device 2 is connected to the dust collector 5 They are connected by air preheater 4, dust remover 5 is connected with desulfurization tower 6, desulfurization tower 6 is connected with chimney 7, and also includes desulfurization wastewater storage tank 8, atomizing nozzle 3, wastewater conditioning tank 11, air compressor 13 , the atomizing nozzle 3 is set on the connecting pipe between the CR denitrification device 2 and the air preheater 4, the atomizing nozzle 3 is connected to the wastewater co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com