High-efficiency compound regenerative electrical energy device

An electric energy device and composite regeneration technology, which is applied in the direction of regenerative fuel cells, circuits, fuel cells, etc., can solve the problems of complexing agent degradation, slow reaction rate, and high energy consumption, so as to achieve rapid regeneration, reduce energy consumption, and realize The effect of secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

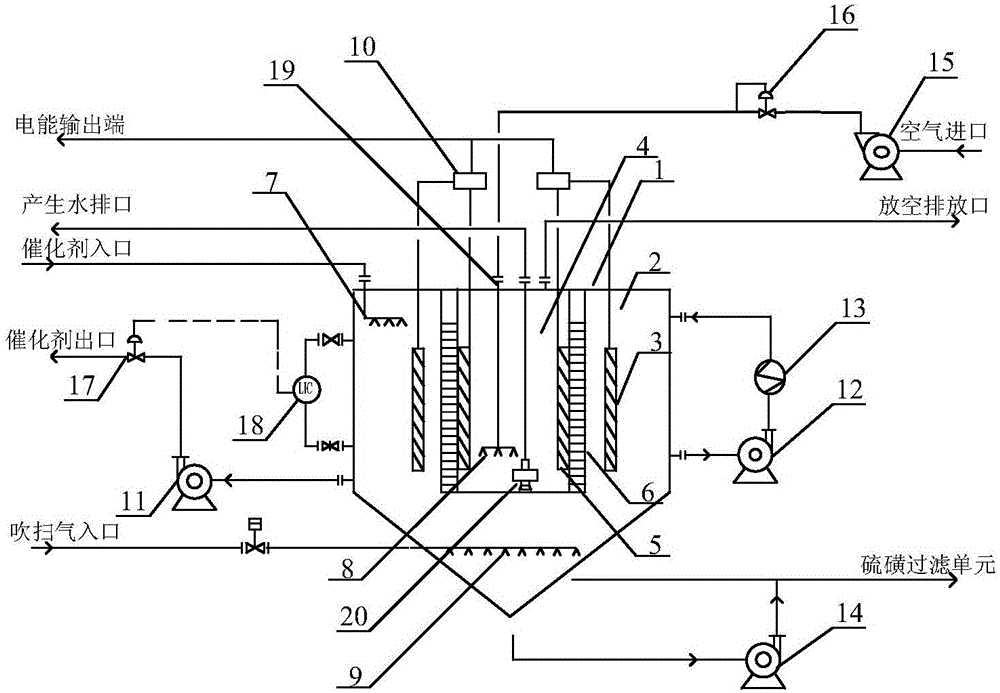

[0016] as attached figure 1 shown

[0017] The invention provides a high-efficiency composite regenerative electric energy device, comprising a reactor 1, an anode chamber 2, an anode plate 3, a cathode chamber 4, a cathode plate 5, a proton exchange membrane module 6, a liquid distributor 7, a gas distributor 8, and a purging Distributor 9, battery load 10, output pump 11, circulation pump 12, heater / cooler 13, slurry pump 14, blower 15, purge gas shut-off valve 16, flow regulating valve 17, magnetic flap level gauge 18, self-powered Type pressure regulating valve 19, submersible pump 20. The anode chamber 2 is arranged in the outer cylinder of the reactor 1; the anode plate 3 is arranged in the inside of the anode chamber 2; the cathode chamber 4 is arranged in the inner cylinder of the reactor 1; the cathode plate 5 is arranged On the inner wall of the cathode chamber 4; the proton exchange membrane module 6 is arranged between the anode chamber 2 and the cathode chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com