Supergravity pressurization oxidation regeneration method of wet oxidation desulfurization process, and special equipment thereof

A wet oxidative desulfurization and hypergravity technology, applied in chemical instruments and methods, catalyst regeneration/reactivation, separation methods, etc., can solve the problems of long gas residence time, large liquid holding capacity, low oxygen solubility, etc. The effect of improving the quality effect and the oxidation regeneration rate of the catalyst, increasing the processing capacity and increasing the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

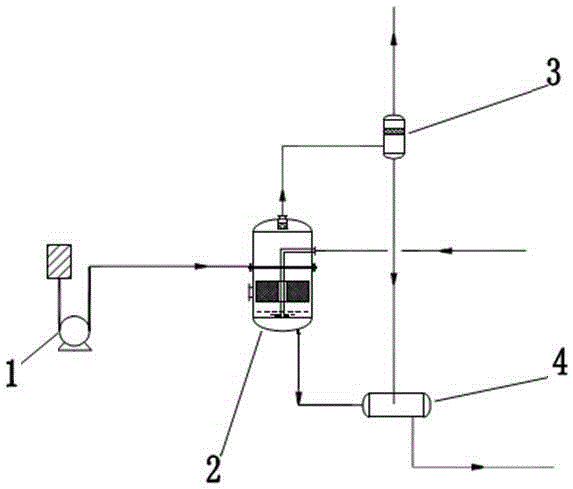

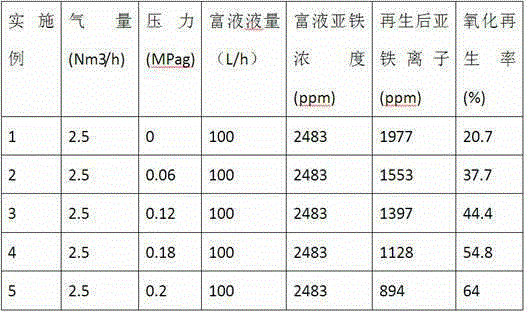

[0019] Embodiment: the supergravity pressurized oxidation regeneration method of wet oxidation desulfurization process, it comprises the following steps:

[0020] 1) The desulfurized rich liquid and the air from the air compressor enter the supergravity machine respectively, and the oxidation reaction occurs in the filler to regenerate the catalyst. The pressure of the supergravity machine is not lower than 0.06MPag; the air volume is 1.2 times higher than the theoretical volume 2 times; the speed of the super gravity machine is between 300rmp and 2000rmp. The theoretical gas volume is determined by the reaction formula 1 / 2O of iron ions and oxygen 2 +H 2 O+2Fe 2+ =OH - +2Fe 3+ Calculated:

[0021] Theoretical volume calculation formula: Q=(V*C / 56 / 4)*22.4 / η

[0022] Among them, Q: theoretical gas volume, unit Nm3 / h;

[0023] V: flow rate of rich liquid entering the supergravity machine, unit m3 / h;

[0024] C: Iron ion content in rich solution, unit g / L;

[0025] η: Ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com