Cutter exploitation method of seabed natural gas hydrates

A mining method and natural gas technology, which is applied in mineral mining, earth square drilling, special mining, etc., can solve the problems of high cost, submarine landslide, and slow effect of chemical reagent injection method, and achieve the effect of small environmental impact and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

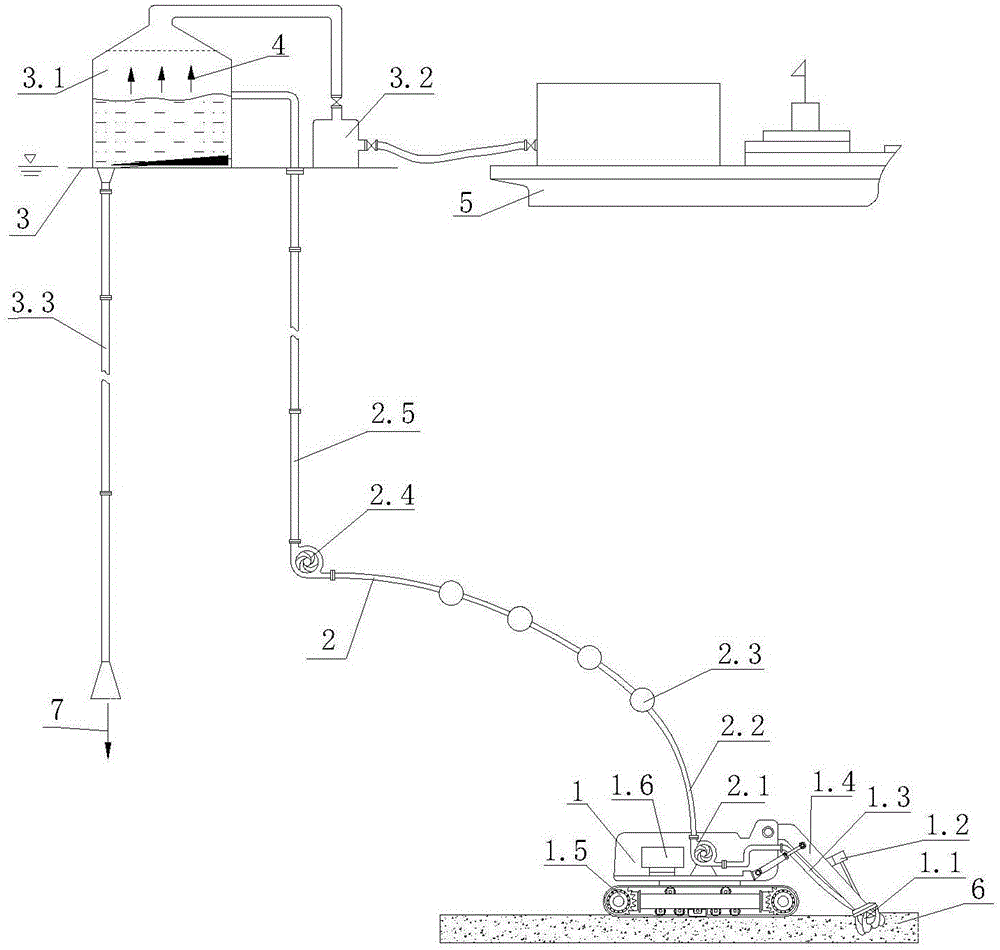

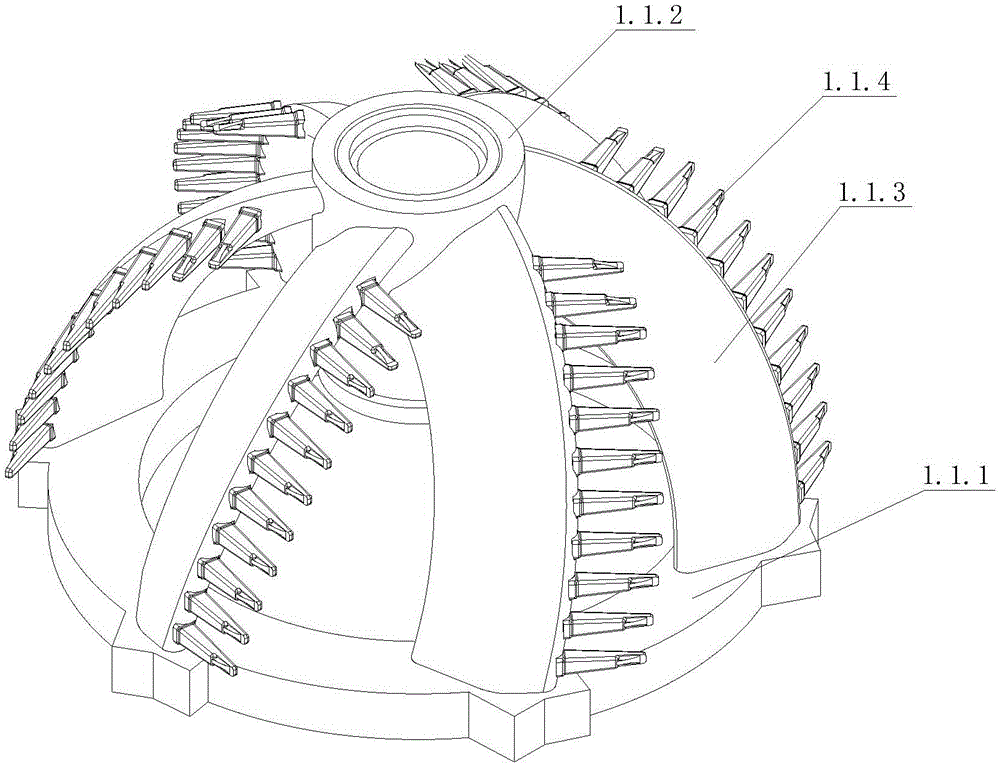

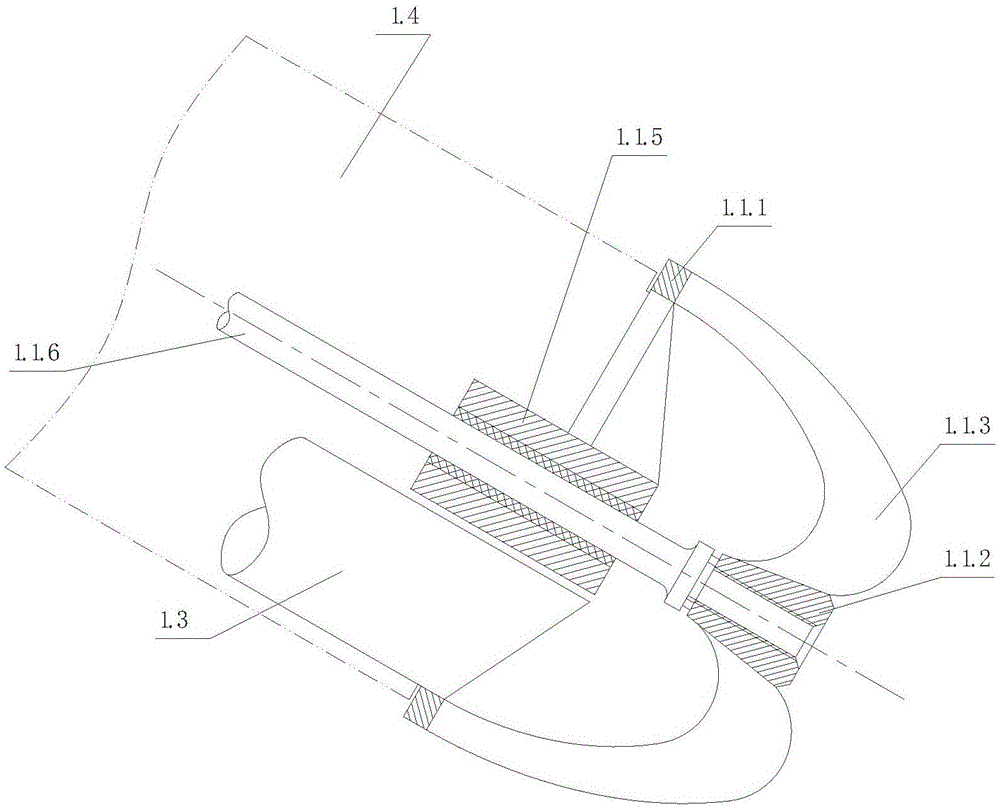

[0033] figure 1 Middle, 1. Hydrate mining vehicle, 1.1, reamer, 1.2, reamer driving mechanism, 1.3, suction pipe, 1.4, reamer arm, 1.5, traveling mechanism, 1.6, power and control system, 2. hydraulic conveying system , 2.1, auxiliary mud pump, 2.2, hose, 2.3, buoyancy ball, 2.4, main mud pump, 2.5, hard pipe, 3, decomposition storage system, 3.1, decomposer, 3.2, storage, 3.3, tailings pipe, 4. Natural gas, 5. Natural gas carrier, 6. Natural gas hydrate, 7. Seabed sediment.

[0034] exist figure 1 Among them, the hydrate mining vehicle (1) consists of a reamer (1.1), a reamer driving mechanism (1.2), a suction pipe (1.3), a reamer arm (1.4), a traveling mechanism (1.5) and a power and control system (1.6 ), the reamer (1.1) is installed on the front end of the reamer arm (1.4), and is used to cut the seabed natural gas hydrate (6) under the drive of the drive shaft of the reamer drive mechanism (1.2), and is connected with the power and control system ( 1.6) are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com