Underground working condition simulation method for controlled pressure drilling experiment and test

A working condition simulation and managed pressure drilling technology, which is applied to the automatic control system of drilling, drilling equipment, wellbore/well components, etc., can solve the problems that the managed pressure drilling technology cannot be tested on the drilling site, and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: The present invention will be further described in detail with a method and device for simulating downhole working conditions used in managed pressure drilling technology and equipment.

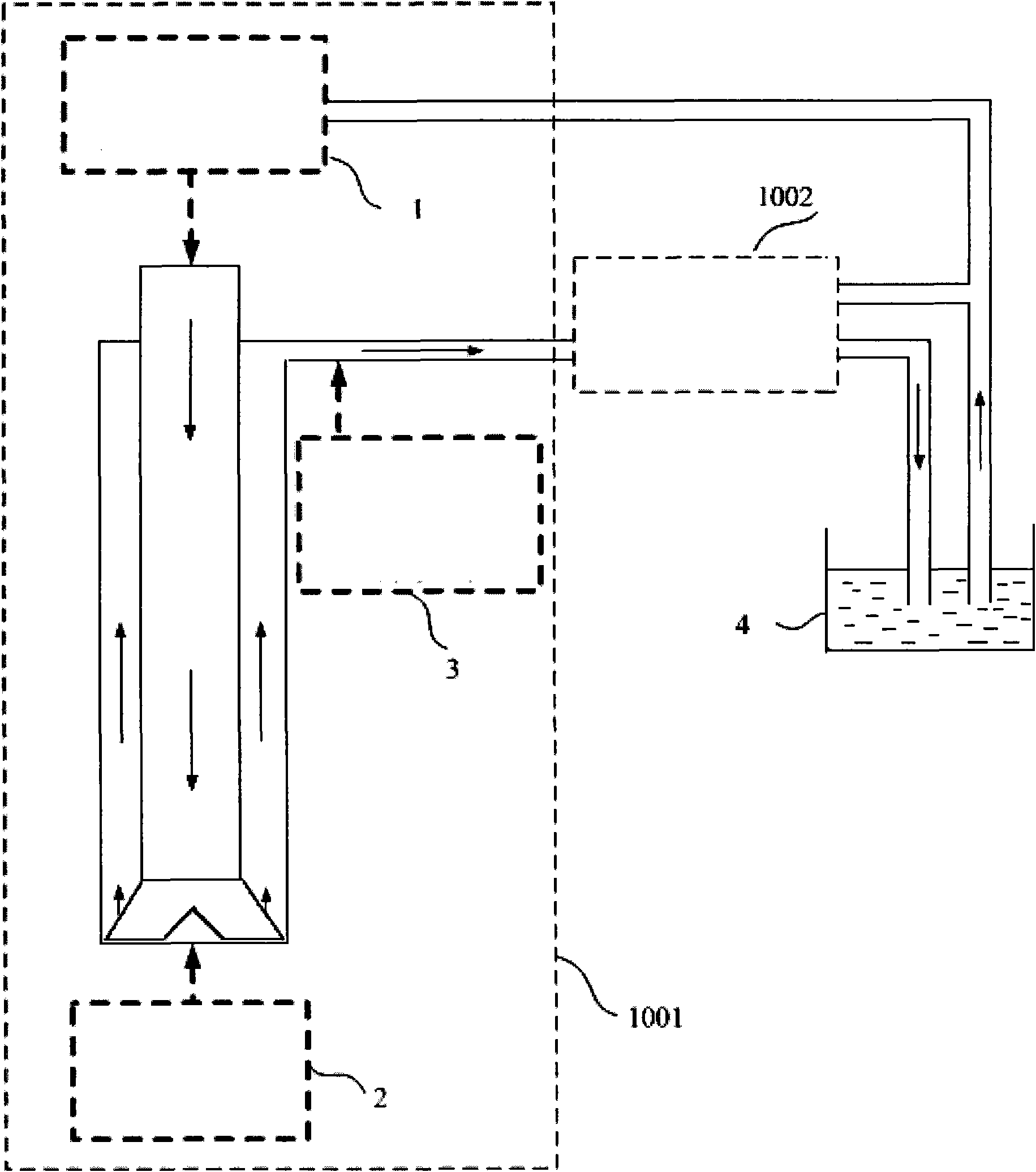

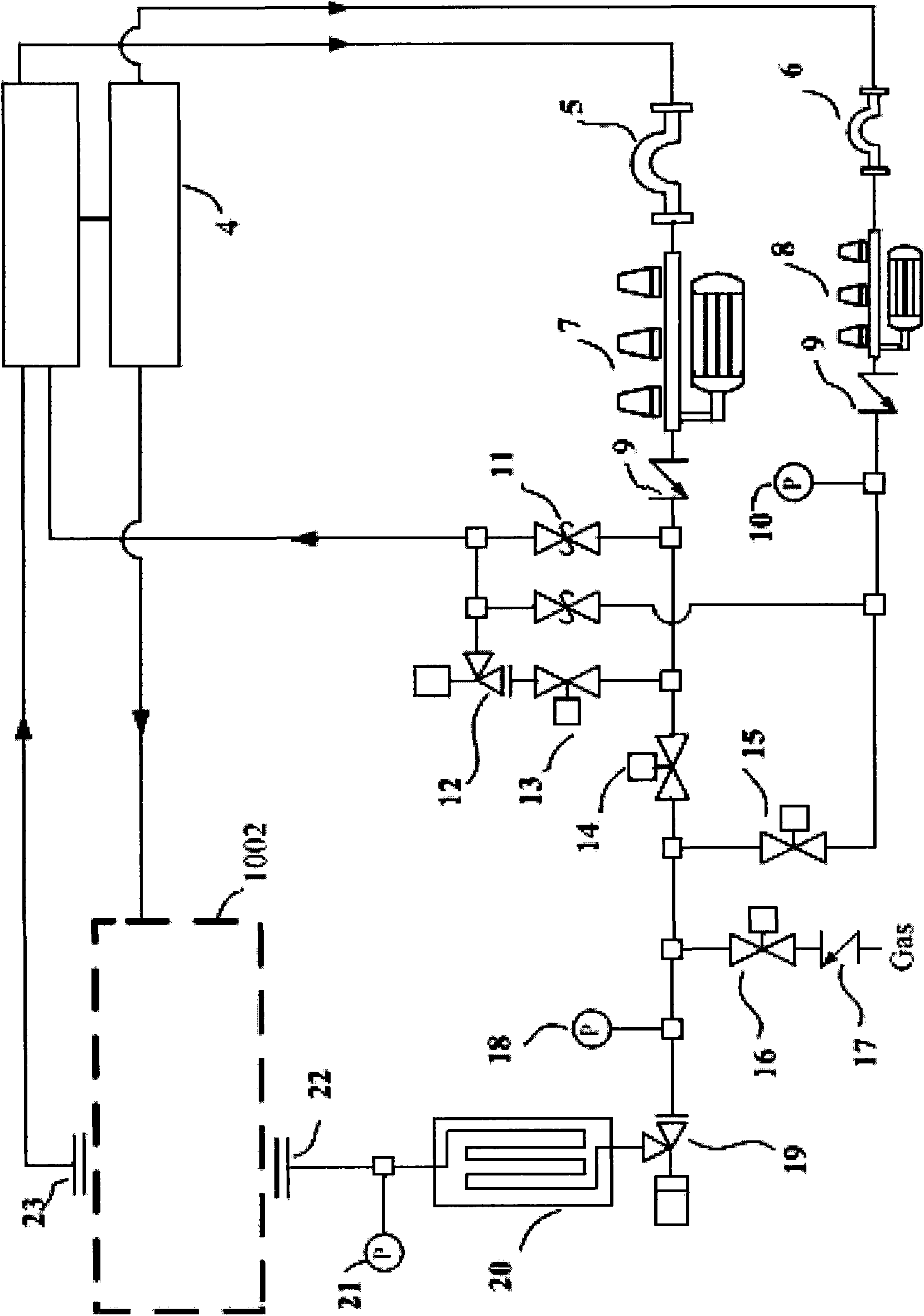

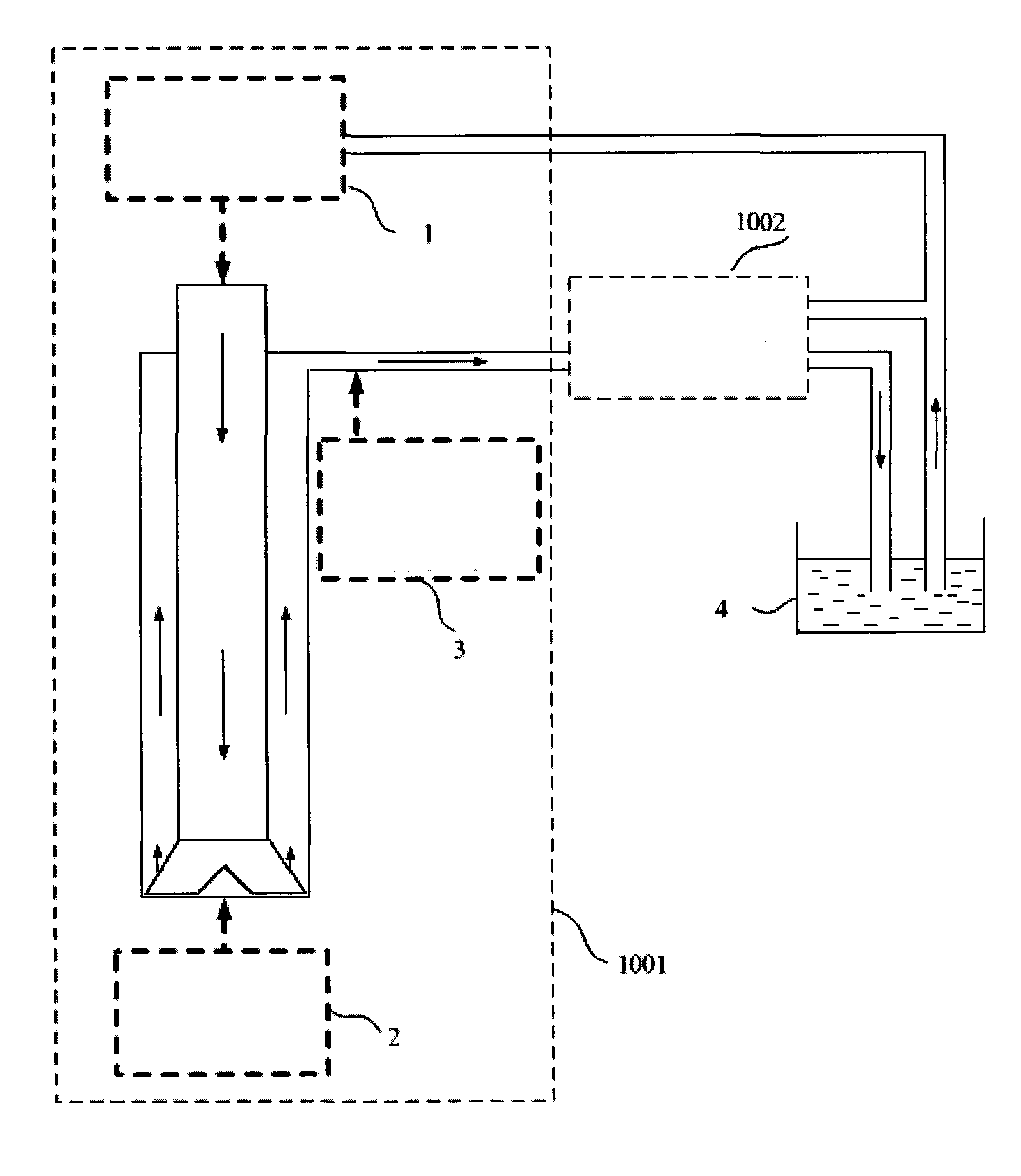

[0042] refer to figure 1 . A method for simulating downhole working conditions for MPD experiments and tests is to conduct experiments and tests in series through a downhole working condition simulator and MPD equipment. The downhole working condition simulator simulates changes in downhole working conditions. The MPD equipment According to the change of the working condition, it can automatically judge, identify the working condition, and carry out pressure control. The specific method is to input the drilling fluid flow rate and density into the downhole working condition simulation device, simulate the change of formation pressure value and lost circulation or well kick, and cause the change of the simulated output parameters such as wellhead back pressure, drilling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com