Sludge treatment method and treatment system

A treatment method and a treatment system technology, applied in the sludge treatment method and its treatment system, and in the field of sludge treatment, can solve problems such as inability to use land, achieve the effects of compact structure, simple treatment method, and reduced treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

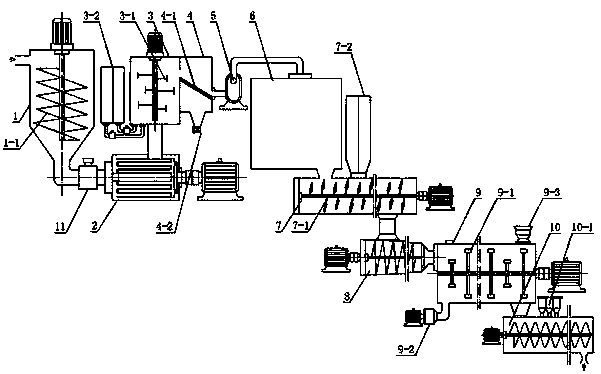

Image

Examples

Embodiment Construction

[0024] A treatment method for sludge, the treatment method has the following steps to achieve:

[0025] ⑴. After the primary treatment, the sludge with a water content greater than 70% is added to the treatment liquid and water for uniform stirring treatment. The water content of the treated sludge is 90-98%:

[0026] ⑵. The sludge uniformly stirred in step ⑴ is subjected to a group of cutting and crushing treatments with different particle sizes according to its flow direction:

[0027] Since the sludge structure contains solids, intermediate water between solids, and microscopic water-containing particles of different sizes formed by solids, the water-containing particles account for a considerable proportion of the water content of the sludge. If the water-containing particles are not protected Dehydration of the sludge until the water content is less than 75% will consume huge energy, such as increasing the dehydration pressure, increasing the dehydration temperature and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com