Heat transfer enhancing and scale preventing and removing device and system for sewage or surface water

A technology that enhances heat transfer and surface water, applied in the energy field, can solve the problems of large amount of dirt cleaning, time-consuming and labor-intensive, low heat transfer efficiency, etc., to achieve the effect of improving anti-blocking performance, ensuring cleaning effect, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

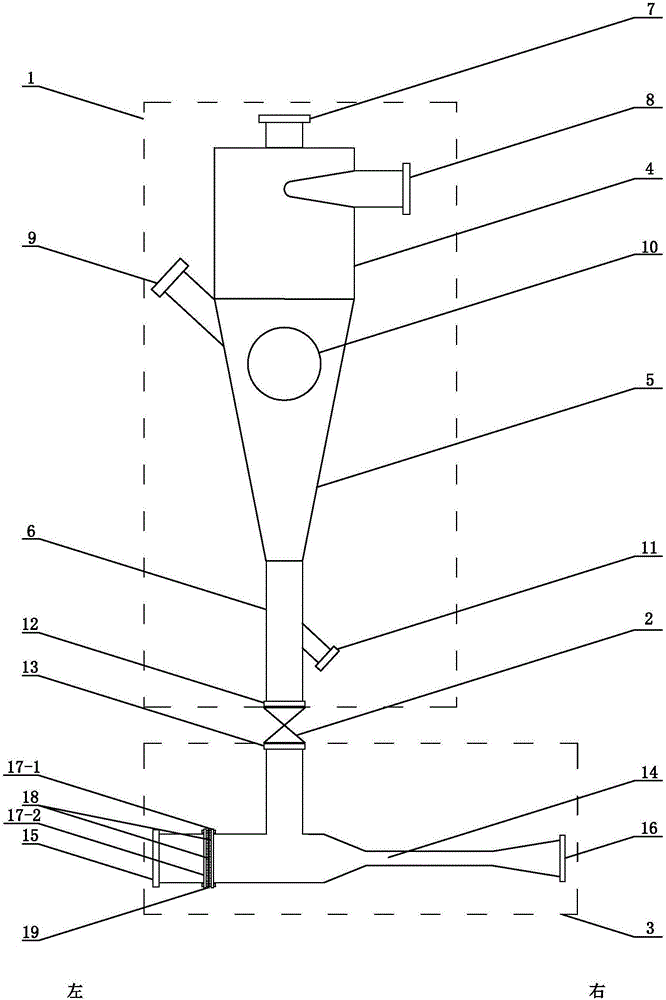

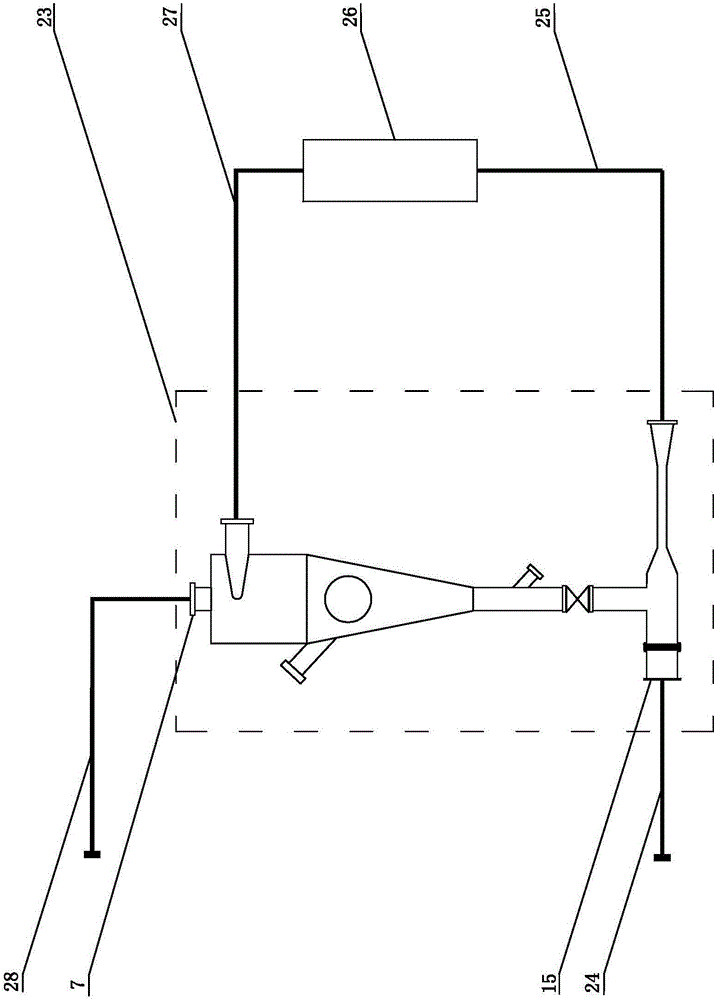

[0030] Specific implementation mode one, such as figure 1 , figure 2 As shown, a kind of enhanced heat transfer and anti-scaling device for sewage or surface water in this embodiment is composed of a cyclone desander 1, a sand regulating valve 2 and an ejector 3. The cyclone desander 1, regulating The sand valve 2 and the ejector 3 are connected from top to bottom; the cyclone desander 1 is composed of a cylindrical cylinder 4, a conical cylinder 5, a sand outlet pipe 6, a cyclone desander overflow port 7 and a cyclone desander. The flow desander is composed of water inlet 8, cylindrical cylinder 4, conical cylinder 5 and sand outlet pipe 6 are welded from top to bottom and connected to each other, the diameter of the bottom of cylindrical cylinder 4 is consistent with the diameter of the top of conical cylinder 5, and the cone The diameter of the bottom of the cylindrical cylinder 5 is consistent with the diameter of the top of the sand outlet pipe 6, the overflow port 7 of...

specific Embodiment approach 2

[0031] Specific implementation mode two, such as figure 1 As shown, the difference between this embodiment and the specific embodiment one is: the cyclone desander 1 also includes the cyclone desander sand inlet 9, the sand viewing window 10 and the cyclone desander sand discharge Port 11, the sand inlet 9 of the cyclone desander and the sand viewing window 10 are all arranged on the side wall of the conical cylinder 5 of the cyclone desander 1, and the sand discharge port 11 of the cyclone desander is arranged on the side wall of the cyclone desander On the side wall of the sand outlet pipe 6 of the device 1. The beneficial effect of this embodiment is that solid particles can be added at any time as required, the running state of the particles can be observed, and the separated redundant solid particles that originally existed in sewage or surface water can be discharged.

specific Embodiment approach 3

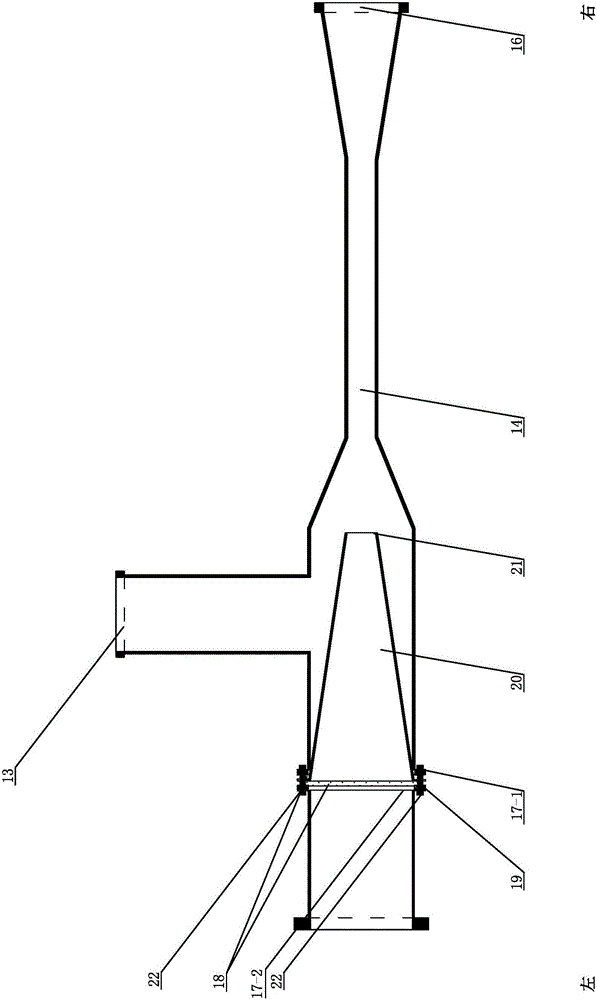

[0032] Specific implementation mode three, such as figure 1As shown, the difference between this embodiment and the specific embodiment one is: the ejector 3 also includes a flange one 17-1, a flange two 17-2, a nozzle flange 19 and a sealing rubber pad 18, The nozzle flange 19 is fixedly connected to the nozzle cavity 20, the flange one 17-1 and the flange two 17-2 are detachably connected to the nozzle flange 19 located in the middle through the bolt 22, and the nozzle flange 19 is respectively connected to the flange one A sealing rubber gasket 18 is set between 17-1 and flange 2 17-2, and flange 1 17-1 and flange 2 17-2 are set on the pipeline where the water inlet 15 of the ejector is located. The beneficial effect of this embodiment is that the nozzle chamber and the nozzle can be replaced at any time according to actual needs, and their sizes can be adjusted, which can improve the efficiency of the ejector and improve the anti-blocking performance of the nozzle.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com