Production technique adopting electric submersible pump and jet sand-discharging pump for combined oil extraction and sand removal

A technology of electric submersible pump and production technology, which is applied in the direction of pumps, pump devices, earthwork drilling and production, etc., to achieve the effects of saving platform space, prolonging the maintenance cycle, and improving oil production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

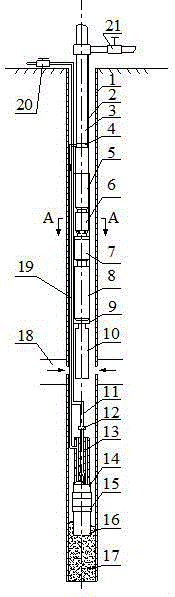

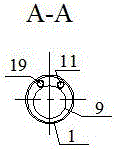

[0011] combined with figure 1 , 2 The present invention is described in further detail.

[0012] Among the main devices involved in the production process of combined oil production and sand cleaning of electric submersible pump and jet pump proposed by the present invention, oil production discharge pipeline 3, electric submersible pump 5, separator 6, protector 7, motor 8, solid cyclone flow removal Sand vessel 10, jet pump 13, check valve 15 are installed sequentially from top to bottom according to process requirements. The protective cover 9 is located outside the electric submersible pump 5, the separator 6, the protector 7 and the motor 8, and can isolate the electric submersible pump from the sand-containing well fluid to ensure that the sand-containing well fluid enters from the inlet of the solid cyclone desander 10 , enter the electric submersible pump after cyclone sand removal, effectively preventing the electric submersible pump from being worn out. The outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com