Oil-based drilling fluid drilling cutting while-drilling treatment method

A technology of oil-based drilling fluid and treatment method, which is applied in the field of oil-based drilling fluid cuttings processing while drilling, can solve the problems of uneconomical, no secondary cleaning device, and affecting the cleaning effect of cuttings, so as to save costs and reduce solids. phase content, to ensure the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

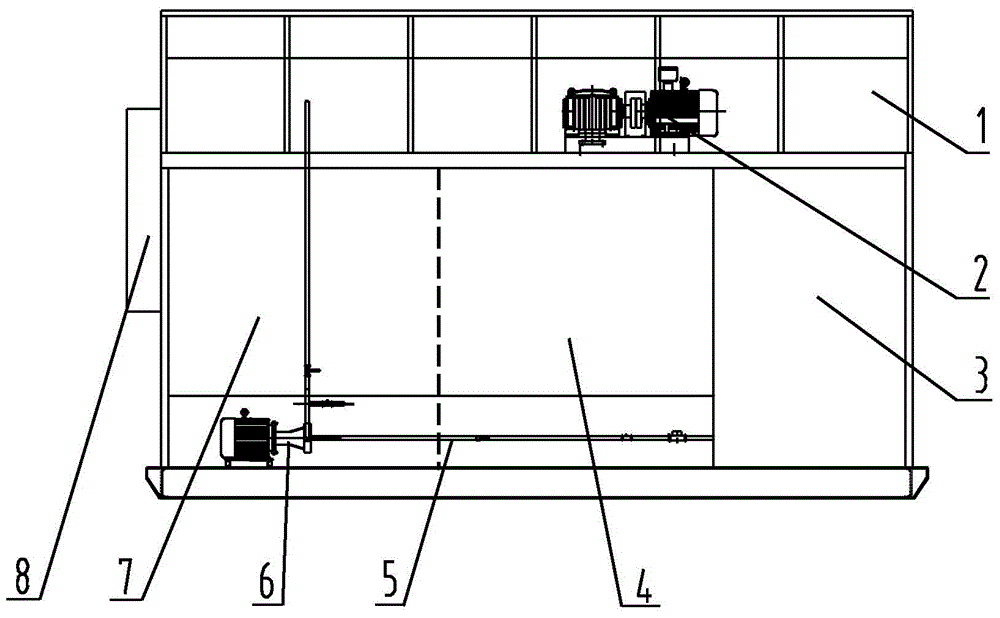

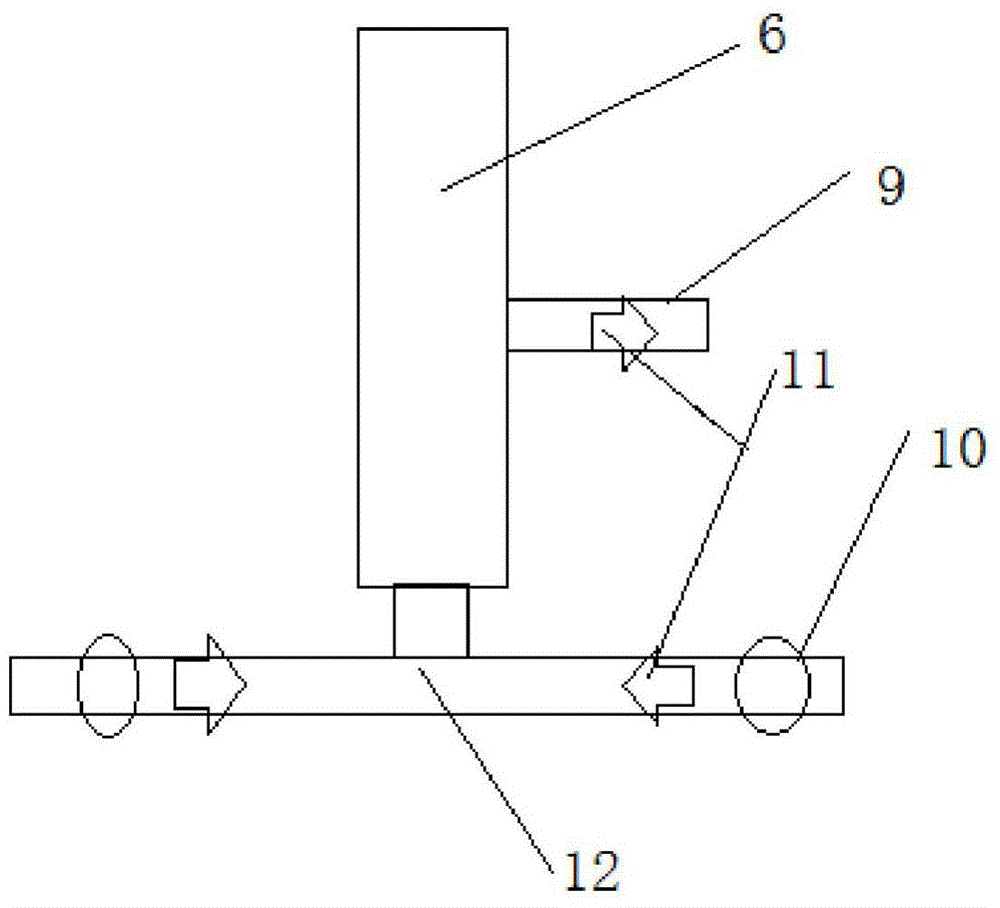

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

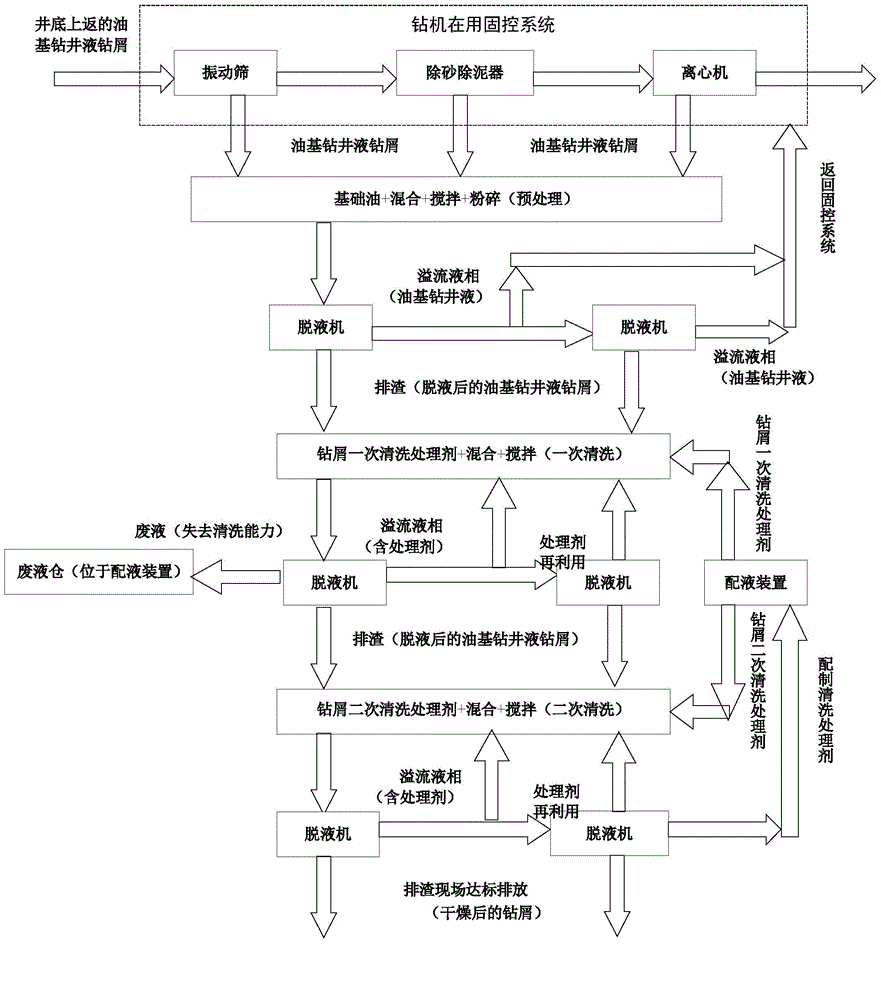

[0027] refer to figure 1 , the oil-based drilling fluid cuttings processing method while drilling of the present invention comprises the following steps:

[0028] Oil-based drilling fluid drilling cuttings processing method: use oil-based drilling fluid recovery and cuttings cleaning to implement step by step:

[0029] The oil-based drilling fluid cuttings produced by the solid control system (equipment) such as vibrating screen, desander, and centrifuge outlet of the well team are discharged into the pretreatment device filled with base oil. The base oil is the oil used by the well team to prepare the oil-based drilling fluid. The base oil is white oil or diesel oil. The mixer completes the dilution, mixing, stirring, and crushing of drilling cuttings and base oil, and then the oil-based drilling fluid cuttings are transported to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com