Mud-sand separator for petroleum drilling

A technology for sediment separation and oil drilling, which is used in earth-moving drilling, flushing wellbore, wellbore/well components, etc. It can solve the problems of low sand removal efficiency of the desander, and achieve light weight, easy transportation, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

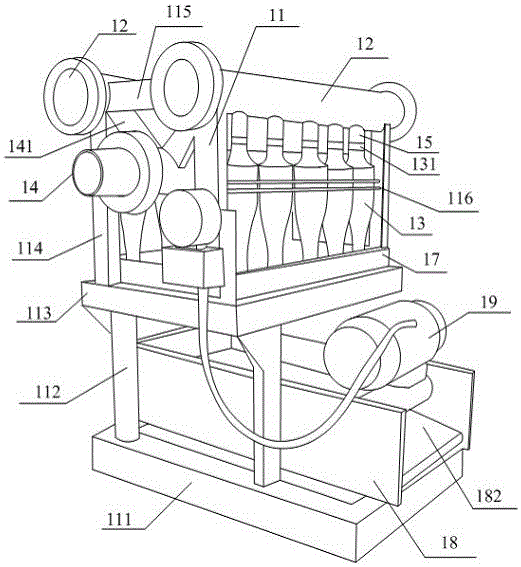

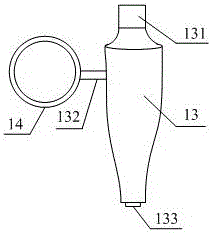

[0027] Such as figure 1 As shown, the sediment separator for oil drilling includes a frame 11, a slurry outlet pipe 12, a feed pipe 14, a cyclone desander 13, a temporary mud storage tank 17, and a vibrating screen 18.

[0028] Described frame 11 comprises: base 111, four first upright posts 112, fixed frame 113, four second upright posts 114, wherein, base 111 and fixed frame 113 are rectangular frame shape, and four first upright posts 112 stand respectively On the four corners of the base 111, the four corners of the fixed frame 113 are respectively fixed on the tops of the four first columns 112; the lower ends of the four second columns 114 are respectively fixed on the four corners of the fixed frame 113 .

[0029] The vibrating screen 18 is fixed on the base 111 .

[0030] The mud temporary storage tank 17 is welded in the fixed frame 113, that is, the outer wall of the mud temporary storage tank 17 is welded to the inner wall of the fixed frame 113, and the bottom of...

Embodiment 2

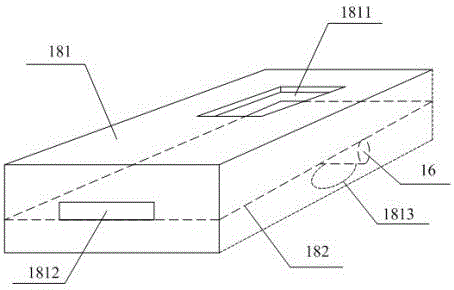

[0043] The difference between this embodiment and Embodiment 1 lies in the structure of the screen box 18 .

[0044] Such as image 3 As shown, in the present embodiment, screen box 18 is made of six panels of front, back, left, right, upper and lower, mud inlet 1811 is offered on the upper panel, silt outlet 1812 is offered on the front panel, and silt outlet 1812 is opened on the lower panel. The mud outlet 1813, the mud inlet 1811 is facing the sewage outlet of the mud temporary storage tank 17;

[0045] The sieve 182 is inclined to be placed high at the back and low at the front, and the lower end of the silt outlet 1812 on the front panel is flush with the sieve 182 to facilitate the flow of silt from the silt outlet 1812 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com