Shale cluster well gas collection platform technological process and method

A process flow and cluster well technology, applied in the field of cluster well gas gathering platform testing and processing, can solve the problem of sand removal and metering accuracy failing to meet the standard requirements, safety, high efficiency, adverse effects of economical operation, and skid-mounted equipment and low degree of modularization, to achieve the effects of easy prying, intensive site layout, and good heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

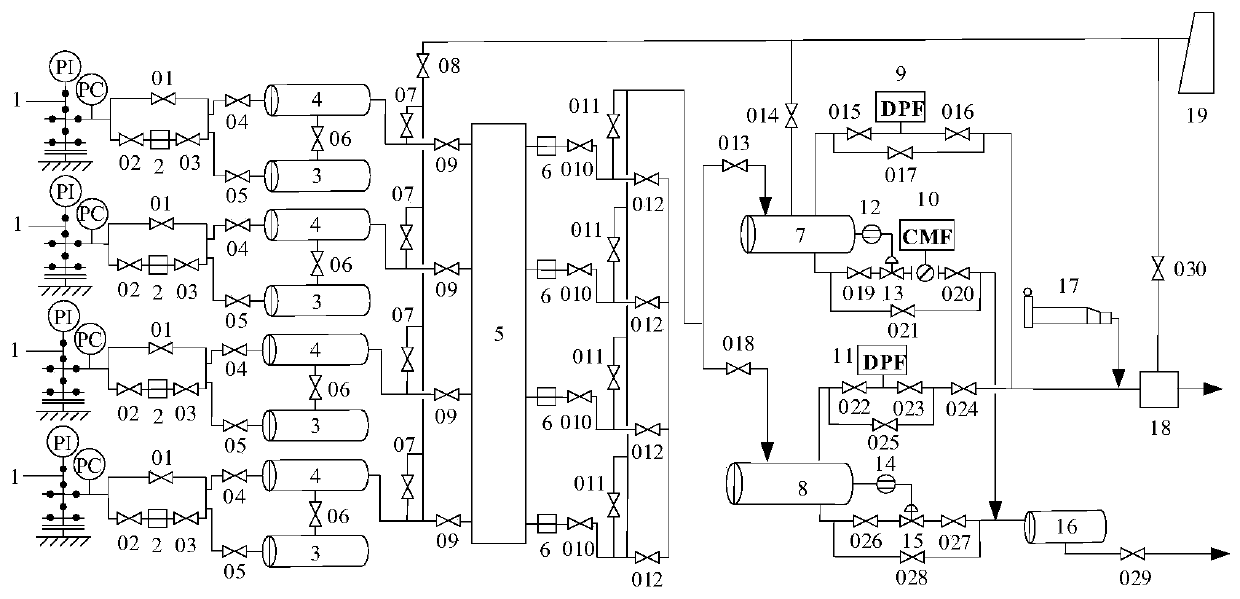

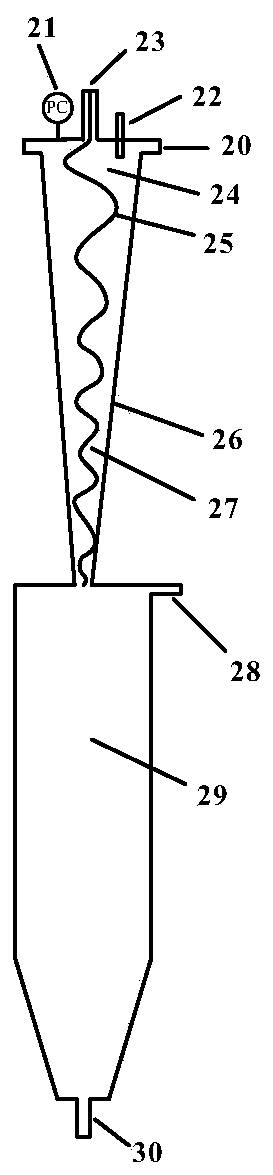

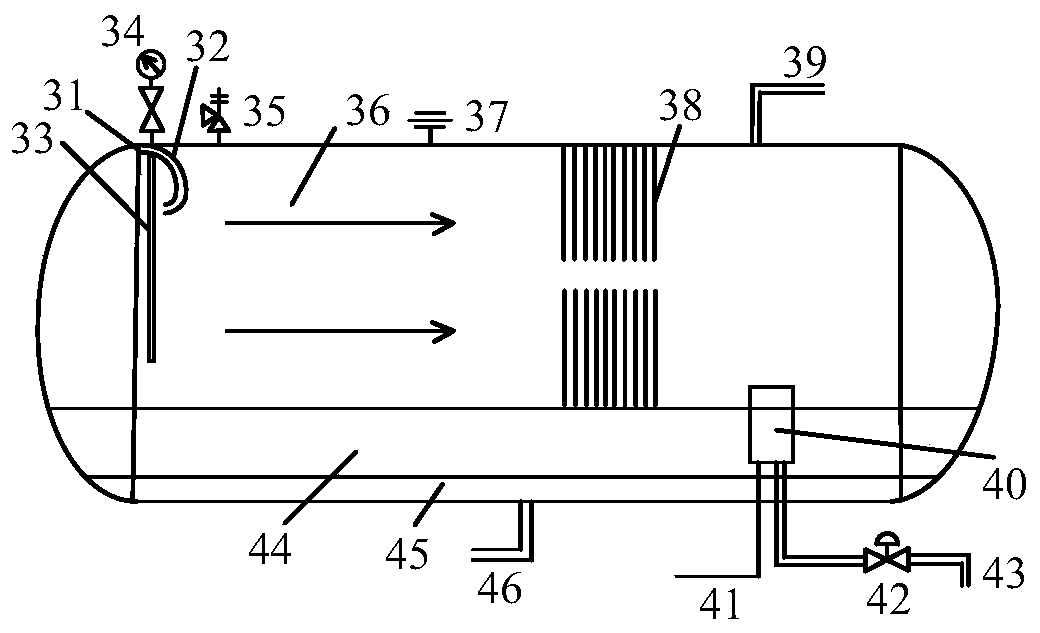

[0022] Such as figure 1 As shown, a shale gas cluster well gas gathering platform process is characterized in that it includes the following:

[0023] 1. During the liquid drainage production period, the liquid volume is large, the sand volume is high, the gas volume is small, and the pressure is high. Therefore, the process flow that can be adopted is: the gas-liquid-sand mixture coming out of the gas tree 1 first passes through the set near the wellhead. The electric throttle valve 2 is used for first-stage throttling; secondly, the cyclone desander 3 is used for centrifugal and sedimentation desanding; and then the filter desander 4 is used for filtration and separation again, so as to reduce the sand particles in the raw gas as much as possible content; and then heated through the 4-well type water jacket heating furnace 5 to prevent ice b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com