Proppant conveying experimental device and method capable of obtaining proppant particle size distribution

A technology of particle size distribution and experimental device, which is applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc., to achieve the effect of overcoming the particle size distribution of test proppant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

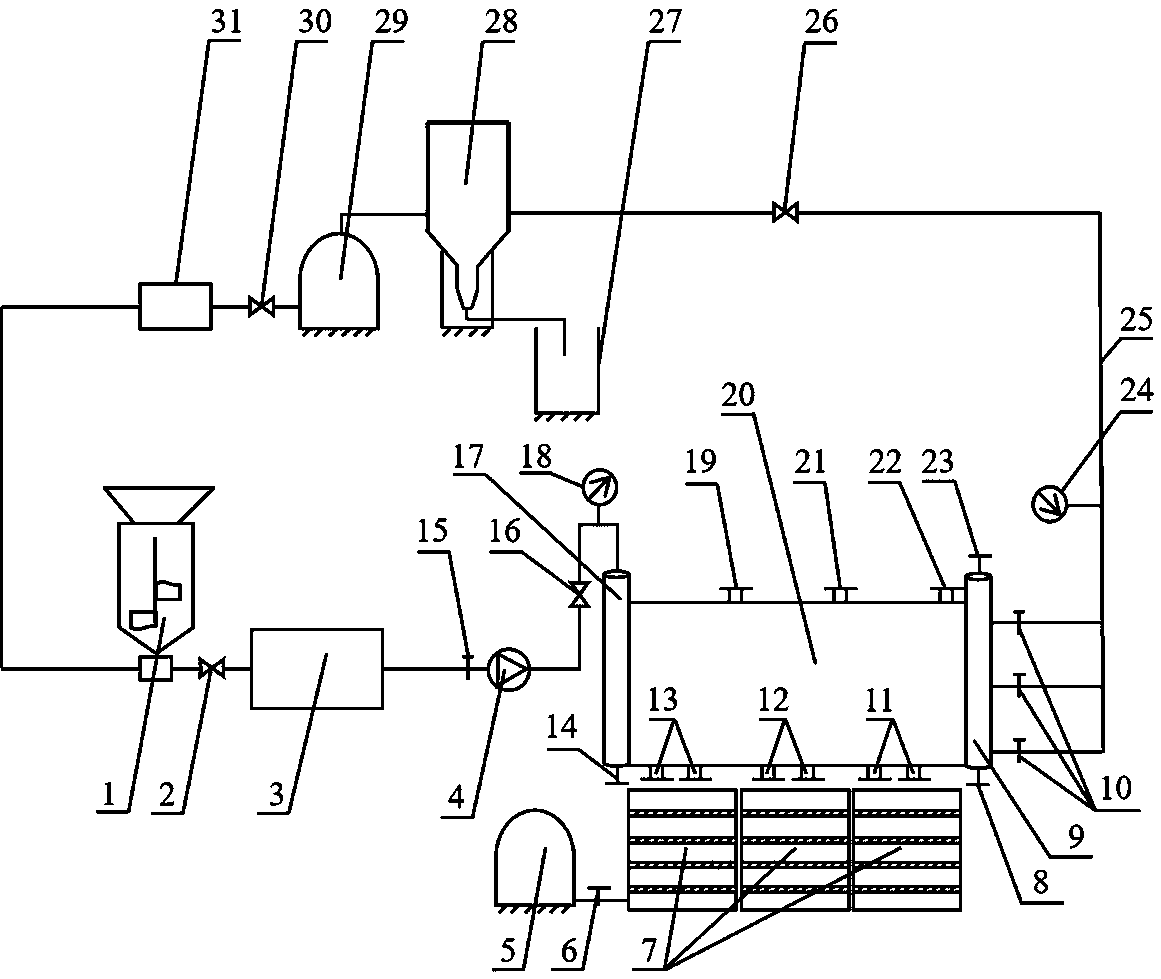

[0027] see figure 1 .

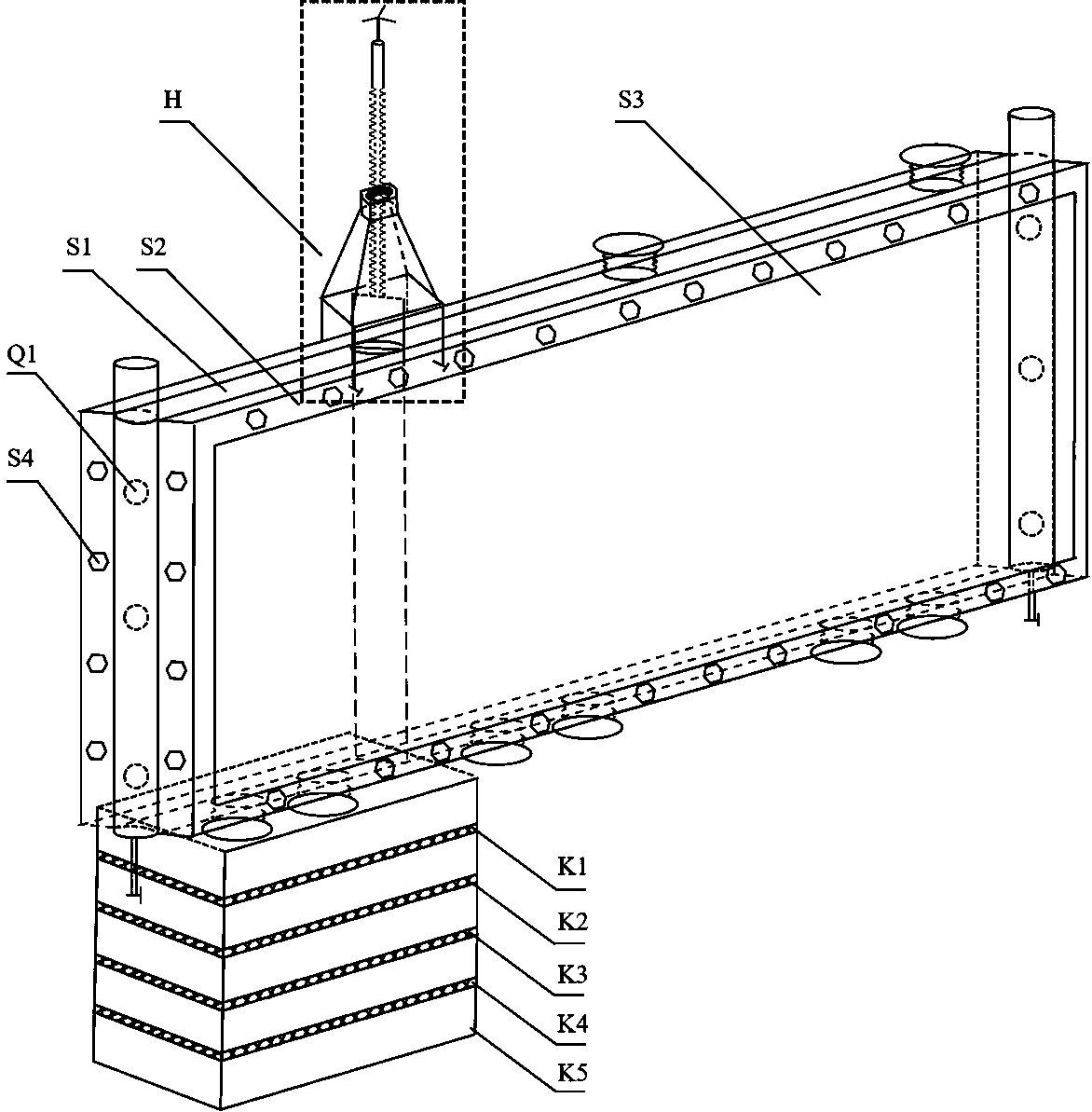

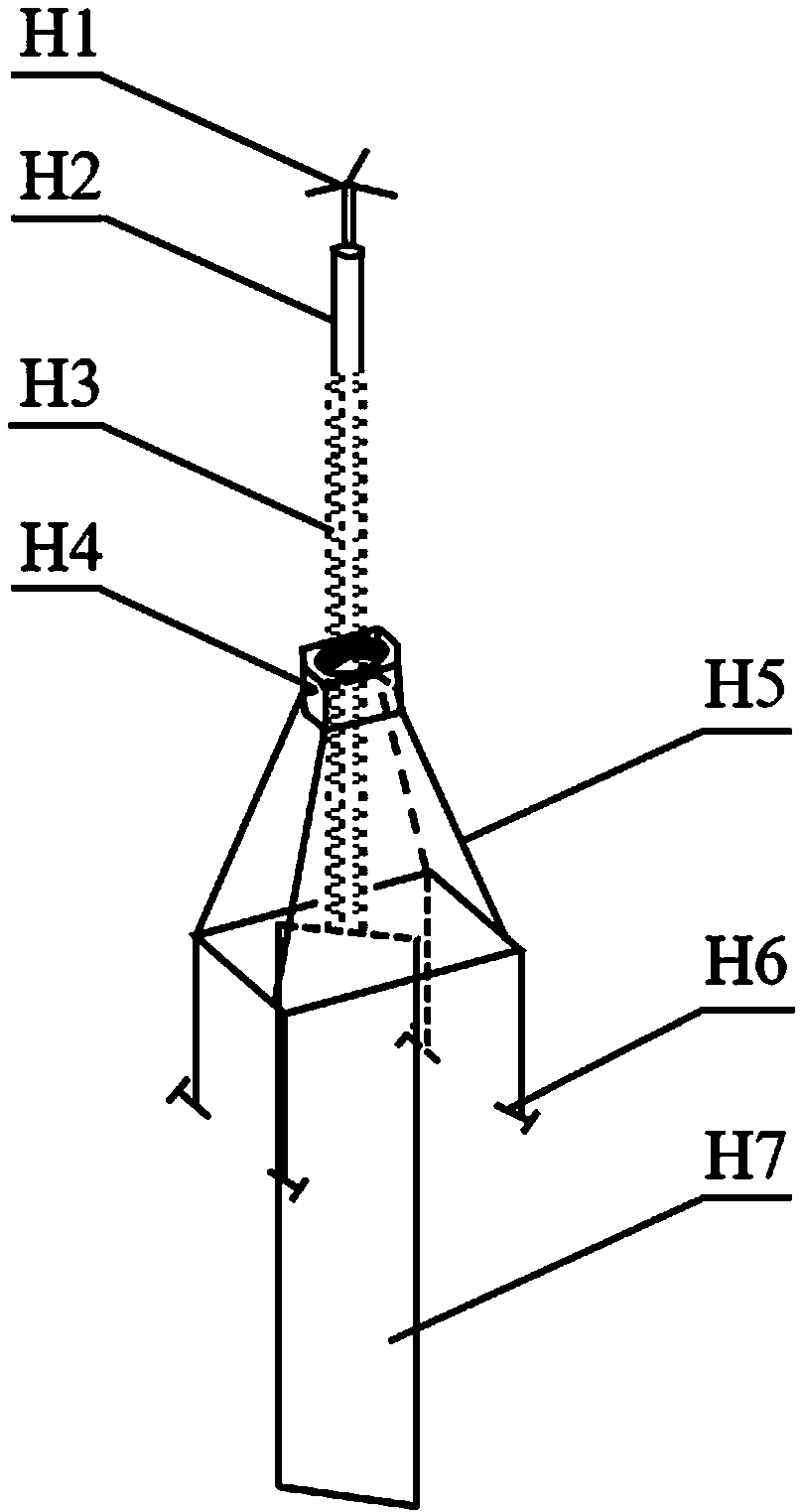

[0028] A proppant conveying experimental device capable of obtaining proppant particle size distribution, consisting of a sand mixing tank 1, a screw pump 3, a simulated inlet wellbore 17, a proppant conveying system 20, a particle size classification system 7, a mechanical division system H, and a simulated outlet The wellbore 9, the cyclone desander 28, the proppant recovery bucket 27, the liquid storage tank 29, and the liquid delivery pump 31 are composed.

[0029]The sand mixing tank 1 is connected to the simulated inlet shaft 17 through the shut-off valve 2 and the screw pump 3, and the pipeline between the screw pump and the simulated inlet shaft is sequentially provided with a regulating valve 15, a flow meter 4, a shut-off valve 16, and a pressure gauge 18; The above-mentioned proppant delivery system 20 is located between the simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com