Crude oil heating furnace for oil fields

A crude oil heating furnace and oil field technology, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of reducing thermal conductivity, leakage or explosion, increasing fuel consumption, etc., to reduce the formation of scaling , reduce wear and blockage, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

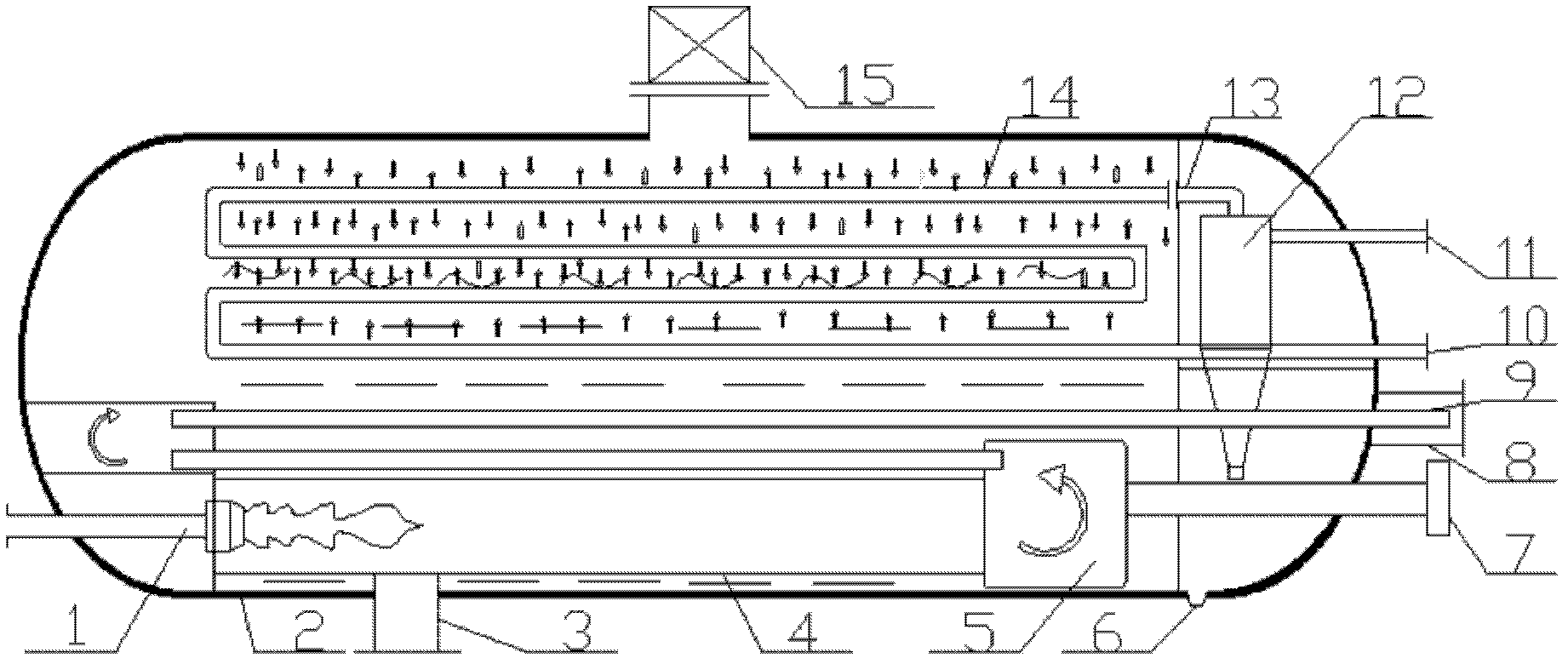

[0015] The present invention consists of a burner 1, a shell 2, an explosion-proof door 3, a furnace 4, a rear combustion chamber 5, a sand outlet 6, a fire tube 7, a smoke outlet 8, a smoke pipe 9, a crude oil outlet pipe 10, and a crude oil inlet pipe. 11. Cyclone desander 12, crude oil overflow pipe 13, heat exchange coil 14, vacuum maintenance device 15; burner 1 is installed below the left end of shell 2; Vacuum maintenance device 15; in the lower part of the housing 2, a combustion chamber composed of a furnace 4 is provided; the burner 1 is located in the combustion chamber; below the combustion chamber, an explosion-proof door 3 is arranged, and the explosion-proof door 3 is connected to the furnace 4 is connected with the housing 2; the rear combustion chamber 5 is connected with the rear end of the combustion chamber; a fire sight 7 is installed at the other end of the rear combustion chamber 5; a smoke outlet 8 is installed at the right end of the housing 2, The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com