Kitchen waste medium-high-temperature combined anaerobic digestion equipment and anaerobic digestion method

A technology of kitchen waste and anaerobic digestion, applied in biochemical equipment and methods, chemical instruments and methods, waste fuels, etc., can solve the problems of heavy metals in fertilizers, poor system stability, and low biogas conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

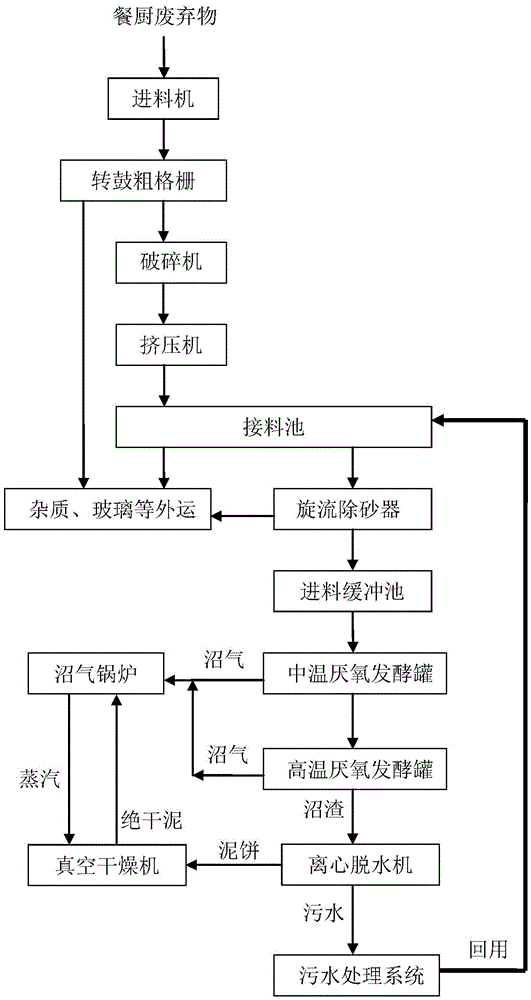

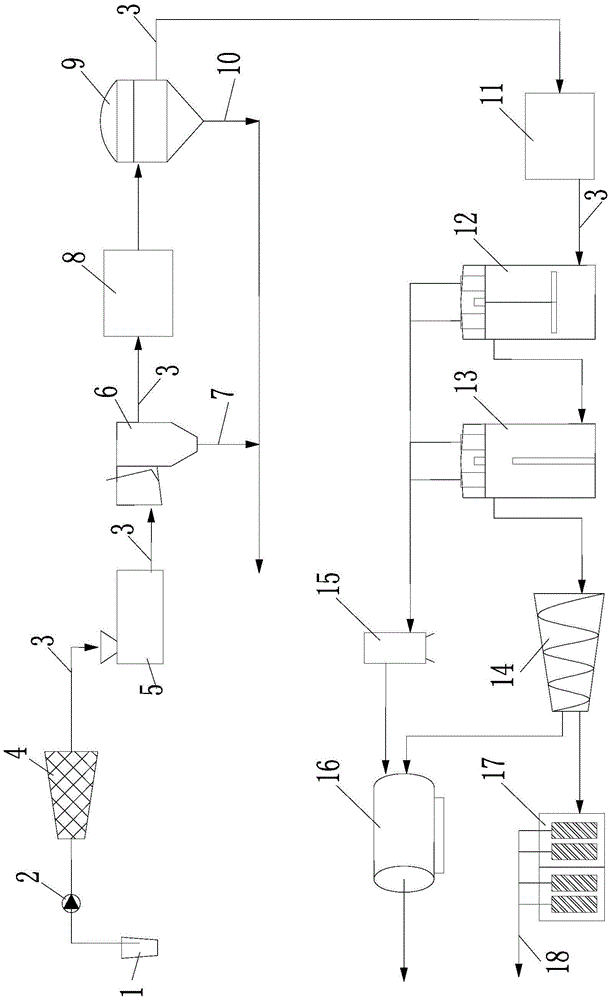

[0062] see figure 2 , the present invention discloses a high-temperature combined anaerobic digestion equipment for kitchen waste. The equipment includes: feeder 1, drum coarse grid 4, crusher 5, extruder 6, receiving pool 8, Cyclone desander 9, feed buffer tank 11, medium temperature anaerobic fermentation tank 12, high temperature anaerobic fermentation tank 13, centrifugal dehydrator 14, sewage purification system 17, vacuum dryer 16, biogas boiler 15.

[0063] The feeder 1, the drum coarse grid 4, the crusher 5, the extruder 6, the receiving tank 8, the cyclone desander 9, the feeding buffer tank 11, the medium temperature anaerobic fermentation tank 12, the high temperature anaerobic Oxygen fermenter 13, centrifugal dehydrator 14, and sewage purification system 17 are connected sequentially, medium-temperature anaerobic fermenter 12, high-temperature anaerobic fermenter 13 are respectively connected to biogas boiler 15, centrifugal dehydrator 14 is connected to vacuum dr...

Embodiment 2

[0080] A high-temperature combined anaerobic digestion equipment for kitchen waste, the equipment includes: a feeder, a drum coarse grid, a crusher, an extruder, a receiving tank, a cyclone desander, and a feeding buffer tank , Medium temperature anaerobic fermentation tank, high temperature anaerobic fermentation tank, centrifugal dehydrator, sewage purification system, vacuum dryer, biogas boiler.

[0081] The feeder, drum coarse grid, crusher, extruder, receiving tank, cyclone desander, feeding buffer tank, medium temperature anaerobic fermentation tank, high temperature anaerobic fermentation tank, centrifugal dehydrator, The sewage purification system is connected in sequence, the medium temperature anaerobic fermentation tank and the high temperature anaerobic fermentation tank are respectively connected to the biogas boiler, the centrifugal dehydrator is connected to the vacuum dryer, and the vacuum dryer is connected to the biogas boiler; the sewage purification system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com