Method for treating incinerated fly ash of domestic garbage with cooperation of cement kiln

A domestic waste incineration and co-processing technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problems of large water consumption, small mixing amount, high salt content, etc. problems, to achieve the effect of reducing downtime for maintenance, increasing processing capacity, and realizing comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

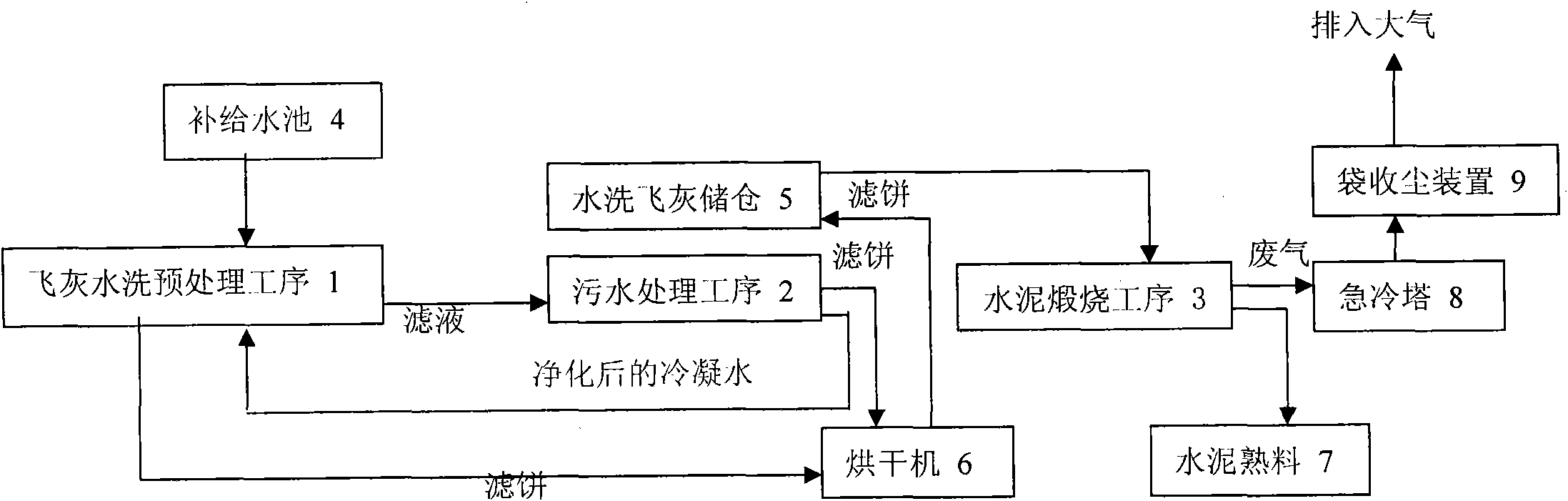

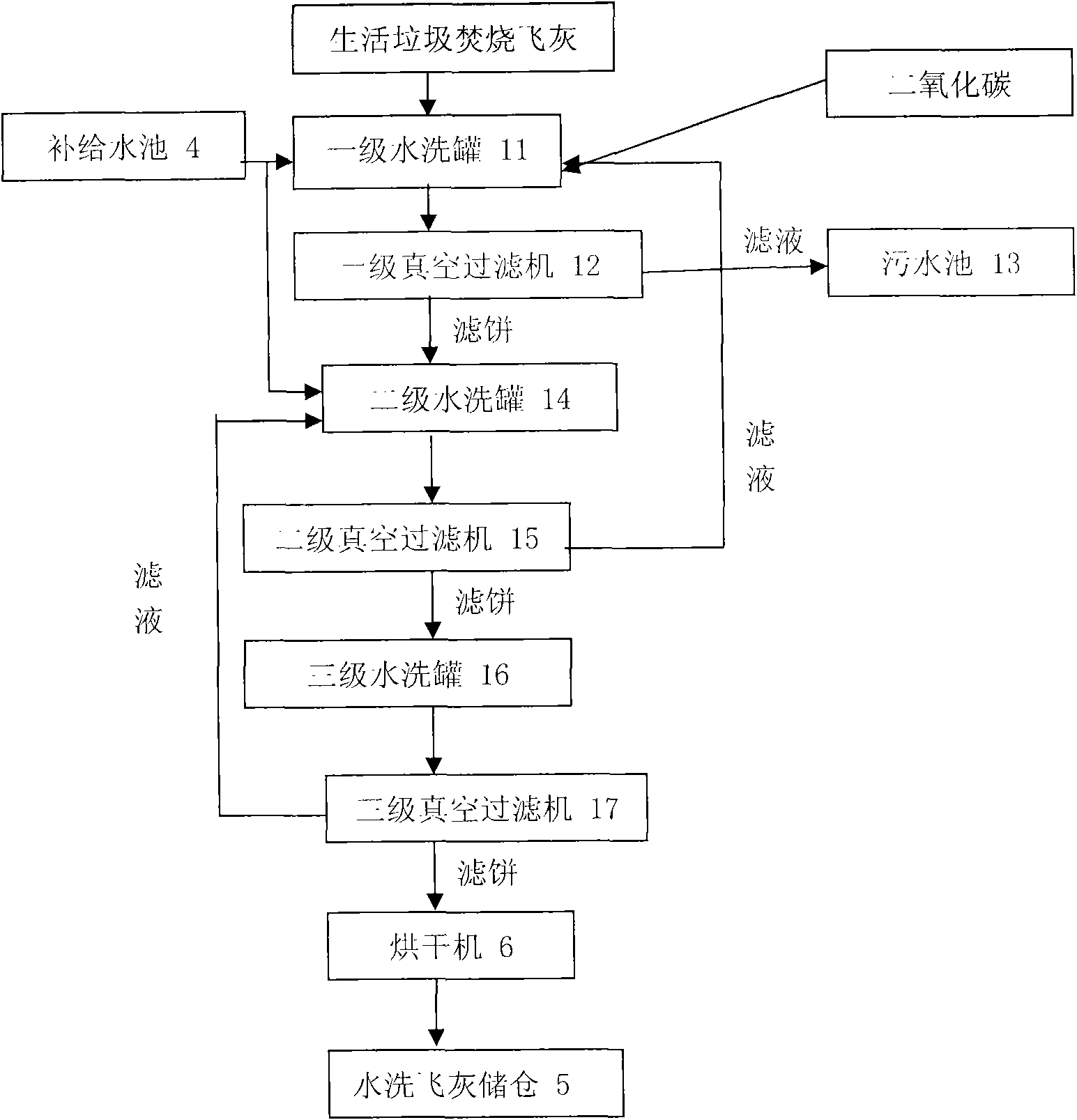

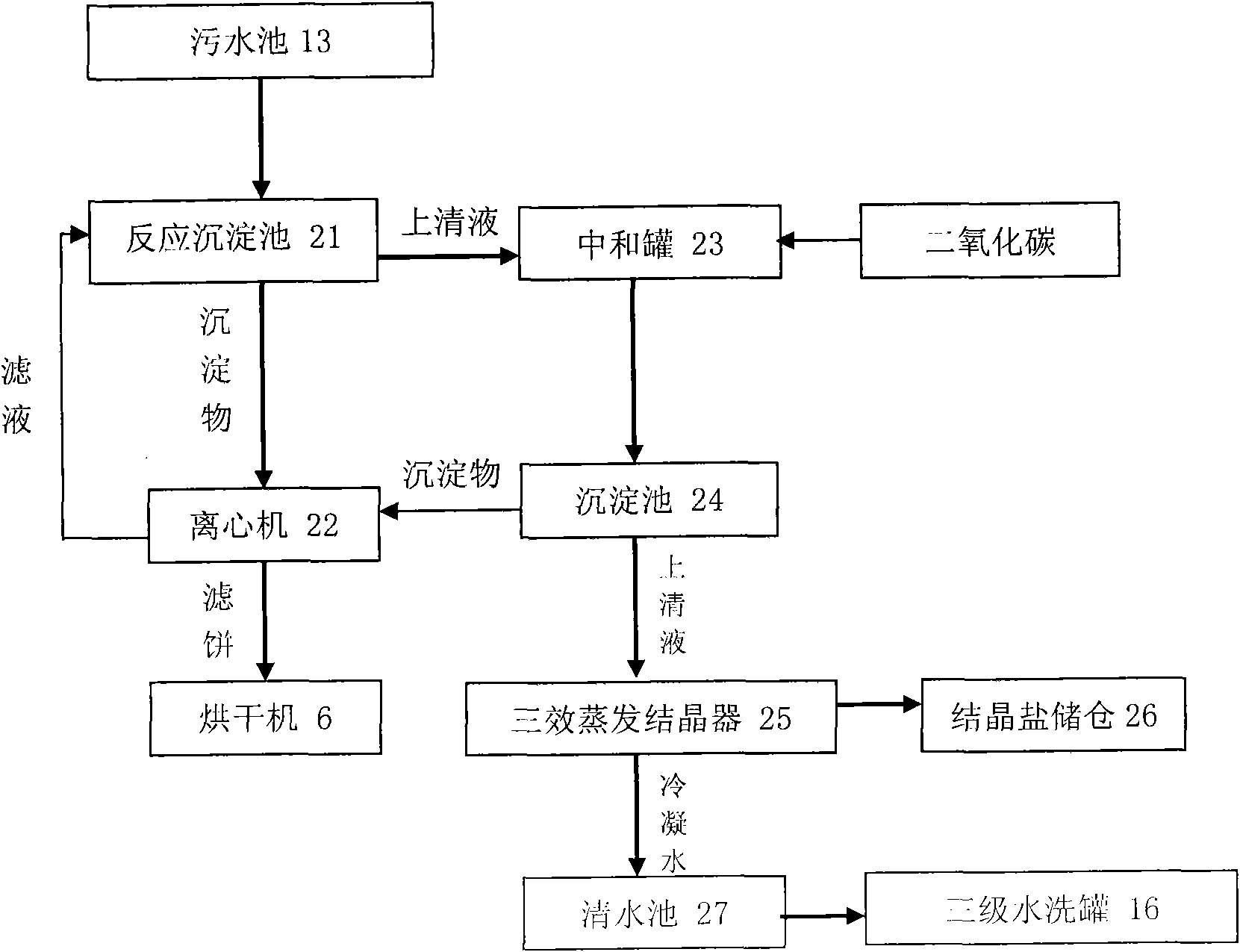

[0017] The method for co-processing domestic waste incineration fly ash in a cement kiln of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 Shown: the technological process of the present invention includes three major steps of fly ash washing pretreatment process, sewage treatment process and calcined cement clinker. Among them, the filter cake obtained by the fly ash washing pretreatment process 1 is dried by the dryer 6 and sent to the washed fly ash storage bin 5, and then enters the cement calcination process 3 to calcinate cement clinker; the obtained filtrate enters the second Step 2 of the sewage treatment process, the filter cake obtained after this step is dried by the dryer 6 and then sent to the washed fly ash storage bin 5; the evaporated condensed water is purified and then returned to the fly ash washing pretreatment process 1 , reused for washing fly ash; can effectively r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com