Treatment method of nickel-cobalt material

A processing method and material technology, applied in the direction of improving process efficiency, etc., can solve the problems that the original non-ferrous metals cannot meet the needs, etc., and achieve the effects of low cost, strong adaptability, and high direct recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

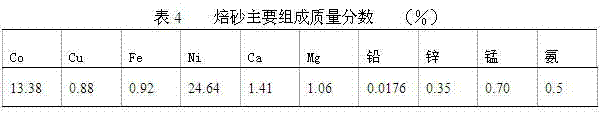

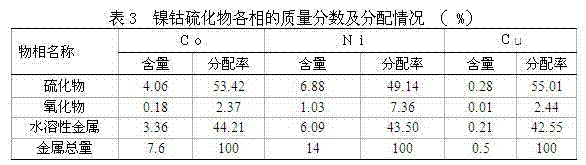

[0030] The main components of nickel-cobalt sulfide materials and the mass fraction and distribution of each phase of nickel-cobalt sulfide are shown in Tables 2 and 3.

[0031] Table 2 Mass fraction of main components of nickel-cobalt sulfide (%)

[0032] co Cu Fe Ni Ca Mg Pb Zn mn S ammonia 7.6 0.5 0.52 14 0.5 0.6 0.01 0.20 0.40 18.5 4.50

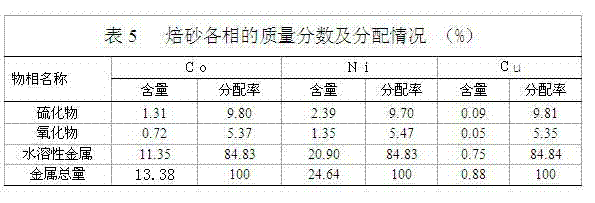

[0033]

[0034] The specific processing method is as follows:

[0035] (1) Oxidation roasting

[0036] Add nickel-cobalt sulfide into the rotary kiln through the feeding screw for oxidation and roasting, and the metal sulfide in the material is oxidized into sulfates that are easily soluble in water and low-valent oxides that are soluble in dilute acid, so as to remove sulfur in the material , The purpose of ammonia. The output flue gas enters the flue gas treatment system for dust collection and desulfurization, so as to achieve the emission of flue gas up to standard. During the roas...

Embodiment 2

[0075] The main composition of the nickel-cobalt material is shown in Table 12.

[0076] Table 12 Mass fraction of main components of high-zinc cobalt carbonate (%)

[0077] co Cu Fe Ni Ca Mg Pb Zn mn water 23 1.5 0.8 0.28 0.4 0.3 0.0010 3.80 8.50 19

[0078] The processing method comprises the following process steps:

[0079] (1) Sulfuric acid leaching: the same as in Example 1. The cobalt leaching rate is 99.8%, the nickel leaching rate is 99.9%, and the copper leaching rate is 99.8%. See Table 13 for the volume mass fraction of each component of the leachate.

[0080] Table 13 Volume mass fraction of each component of leachate (g / l)

[0081] co Cu Fe Ni Ca Mg Pb Zn mn h 2 SO 4 Leachate 43.01 2.81 1.50 0.52 0.75 0.56 0.0019 7.11 15.89 28

[0082] (2) Copper removal by N902 extraction: Same as Example 1. The extraction process is an acid production process, the sulfuric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com