Purification method and purification equipment for organic solvent

A technology of organic solvent and purification method, applied in chemical instruments and methods, separation methods, fractionation and other directions, can solve the problems of poor economy, high purification cost, unable to meet the needs of use, etc., and achieve the effect of high economy and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

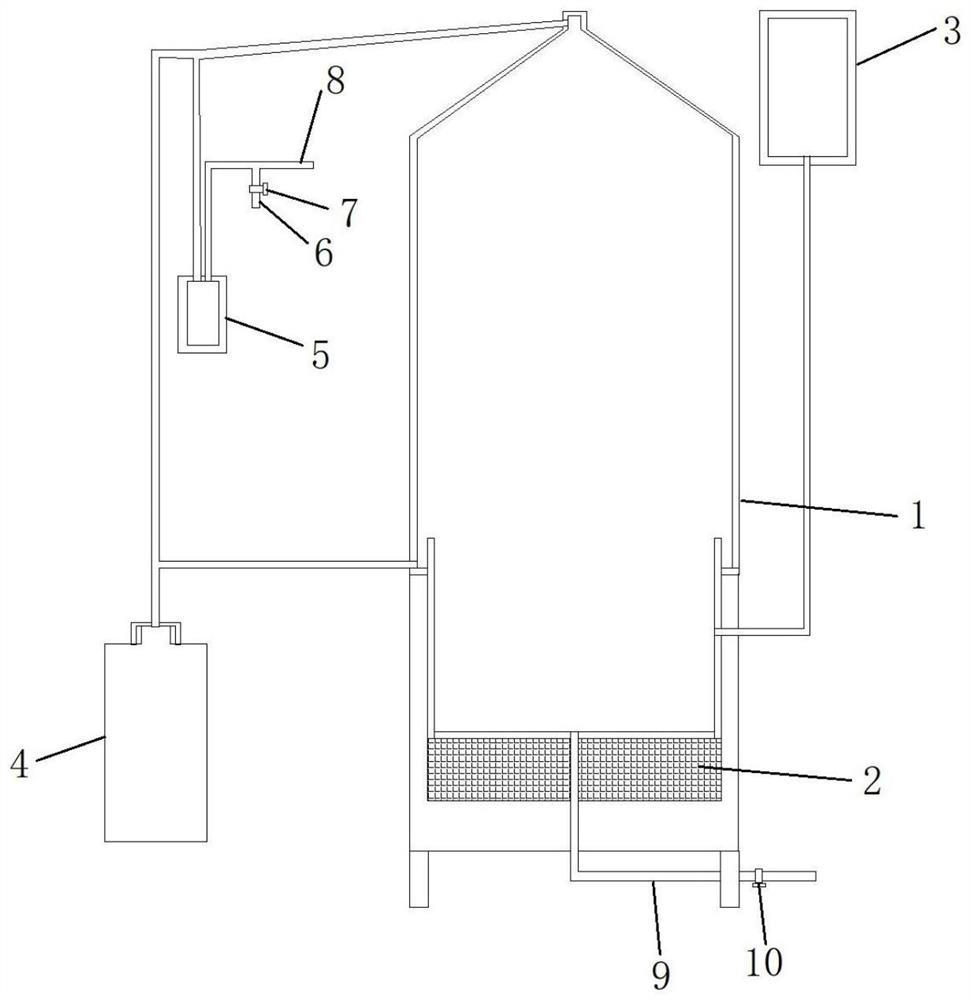

[0041]This embodiment discloses a purification equipment for organic solvents, such as figure 1 As shown, the purification equipment includes a small rectification device 1, a raw material tank 3, a product tank 4 and a steam condensation tank 5. A heating device 2 is installed at the bottom of the small rectification device 1, and the side of the small rectification device 1 is provided with a raw material port and a discharge. The raw material port and the discharge port are respectively connected with the raw material tank 3 and the product tank 4 through pipelines. The top of the small rectification device 1 is provided with a gas balance port, and the gas balance port is connected with the steam condensing tank 5 through pipelines. The condensation tank 5 is connected with a pressure relief pipe 6 and a protective gas inlet pipe 8 , and a pressure relief valve 7 is installed on the pressure relief pipe 6 . The small rectification device 1 is selected as the equipment for ...

Embodiment 2

[0047] A kind of purification method of organic solvent (nitrogen-methylpyrrolidone), comprises the steps:

[0048] S1, 0.1g of mannitol is added to 1.4kg of technical grade nitrogen-methylpyrrolidone, fully mixed to obtain a mixed solution;

[0049] S2, adopt inert gas argon to purge the purification equipment in embodiment 1 for 5 minutes, then add the mixed solution into the small rectification device 1 from the raw material tank 3;

[0050] S3, regulate the heating device 2, adjust the temperature at the bottom of the small rectification device 1 to 121 ° C, the distillation product enters the product tank 4 from the discharge port, and wait for 48 hours to obtain 500g of ultra-high-purity nitrogen-methylpyrrolidone ;

[0051] S4. Continue to distill and add raw materials regularly. About every 48*2 hours, 1kg of product can be obtained, 1kg of raw materials are added every four days, and the purification equipment is emptied every 14 days.

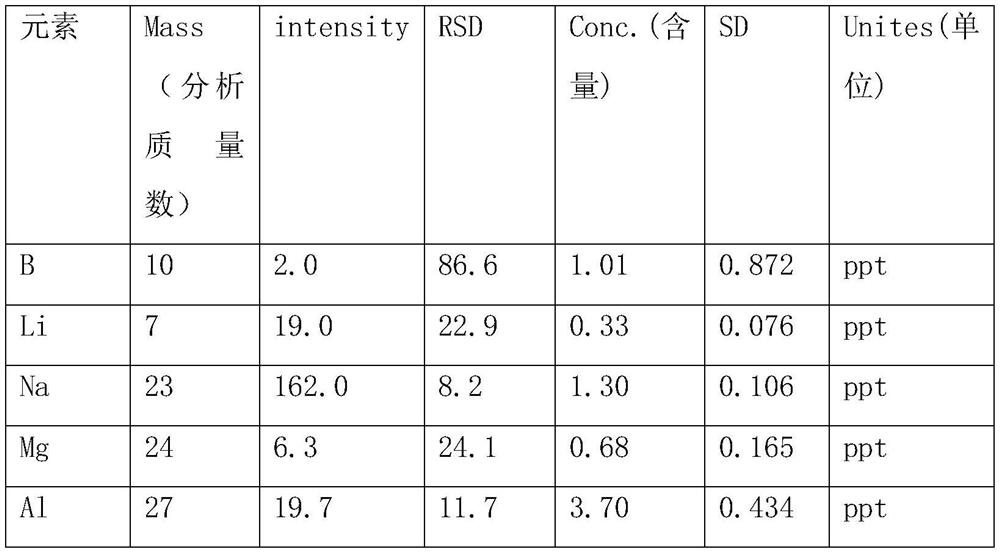

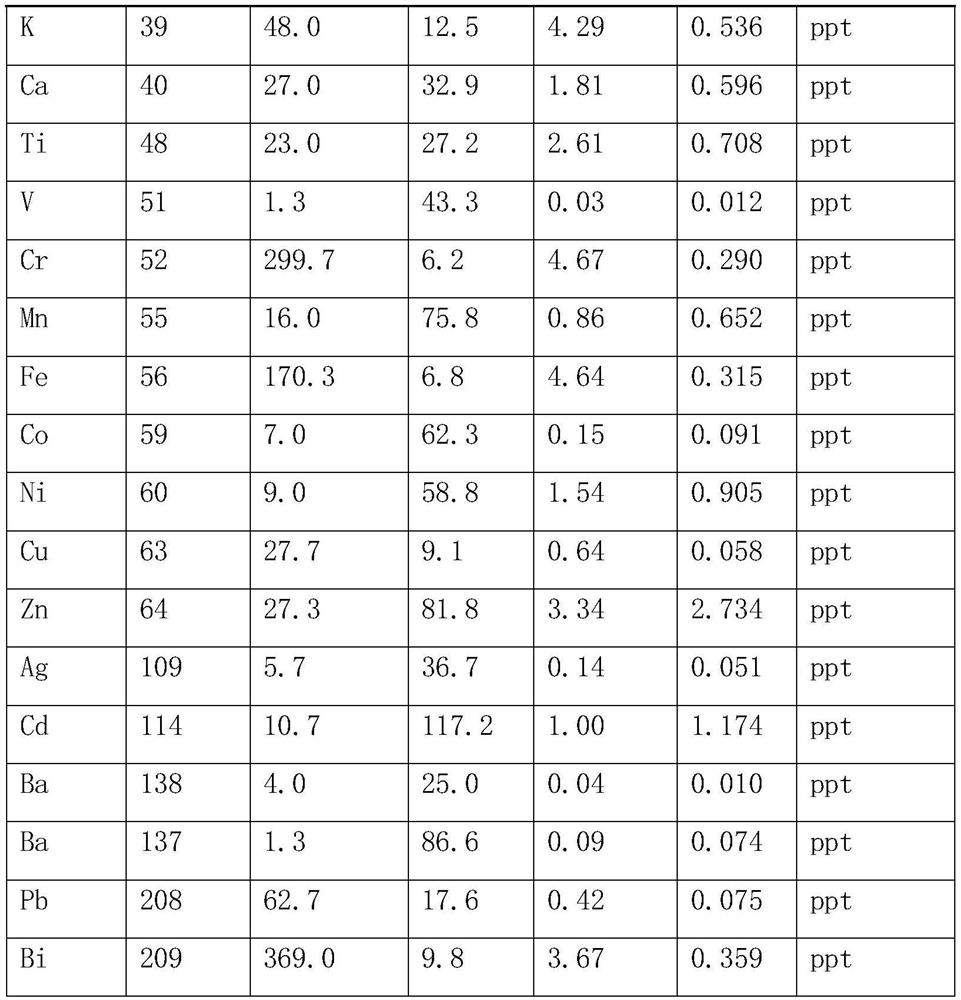

[0052] Inductively coupled p...

Embodiment 3

[0058] A kind of purification method of organic solvent (isopropanol IPA), comprises the steps:

[0059] S1, add 0.1g of mannitol to 1.0kg of technical grade isopropanol, fully mix to obtain a mixed solution;

[0060] S2, adopt inert gas argon to purge the purification equipment in embodiment 1 for 5 minutes, then add the mixed solution into the small rectification device 1 from the raw material tank 3;

[0061] S3, regulating and controlling the heating device 2, adjusting the bottom temperature of the small rectifying device 1 to 80° C., the distillation product enters the product tank 4 from the discharge port, and waits for 48 hours to obtain 500g of ultra-high-purity isopropanol;

[0062] S4. Continue to distill and add raw materials regularly. About every 48*2 hours, 1kg of product can be obtained, 1kg of raw materials are added every four days, and the purification equipment is emptied every 14 days.

[0063] Inductively coupled plasma mass spectrometer (model PerkinEl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com