Method for treating oil sludge

A treatment method and technology for oil sludge, which are applied in the fields of sludge treatment by temperature control, dewatering/drying/concentrating sludge treatment, pyrolysis treatment of sludge, etc., can solve the problem of high energy consumption, low investment and operating costs, and unused centimeter utilization and other problems, to achieve the effect of high processing efficiency, small equipment scale and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

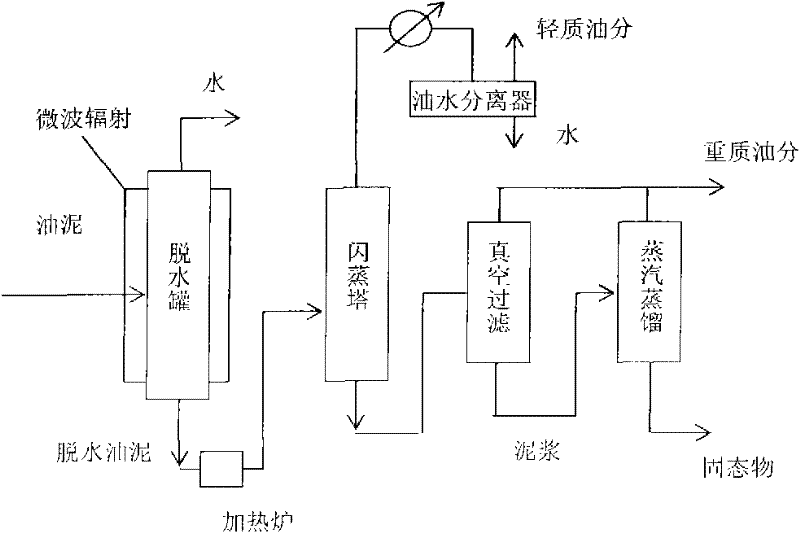

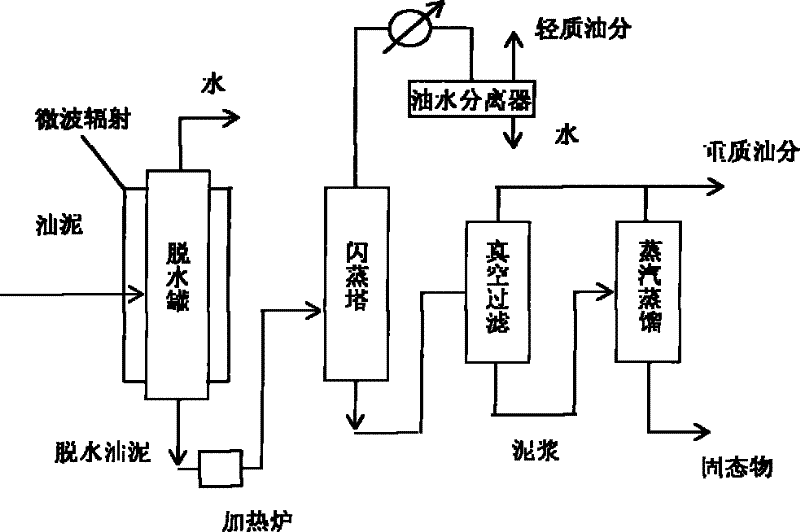

[0017] The specific embodiment of the present invention is described by taking oil sludge at the bottom of a refinery oil tank as an example. The present invention is particularly suitable for oily sludge with high water content, so the selected oily sludge contains 75.5% water, 14.2% oil, and the rest is solid matter (the percentage involved in the present invention is based on weight).

[0018] The sludge is pumped into the dewatering tank. The dehydration tank is externally connected with a microwave radiation device. The microwave radiation frequency is 2450MHz and the power is 800W. Radiation time 40min / m 3 . After microwave demulsification and dehydration, the moisture content of sludge can be reduced to 32%. The dehydrated oil sludge is heated to 250°C and sent to the flash tower for flash evaporation. Water vapor and light hydrocarbon vapor are obtained at the top of the tower, which are condensed and separated by an oil-water separator to obtain light oil, and th...

Embodiment 2

[0020] The specific embodiment of the present invention is described by taking oil sludge at the bottom of a refinery oil tank as an example. Oil sludge contains 45% oil, 41% water, and the rest is solid matter. Process flow is with embodiment 1. The microwave radiation frequency is 2450MHz and the power is 1500W. Radiation time 15min / m 3 . After microwave demulsification and dehydration, the moisture content of sludge can be reduced to 15%. The heating temperature for the flash treatment is 200°C. The steam distillation is at 450°C and the pressure is controlled at 0.3MPa. The final oil recovery was 97.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com