Method for extraction of pyridine compounds from coal tar

A technology of phenolic compounds and pyridines, which is applied in the field of coal chemical industry, can solve problems such as affecting oil quality, increasing hydrogen consumption, poisoning of hydrogenation catalysts, etc., so as to make up for the gap of rare resources and improve the utilization level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

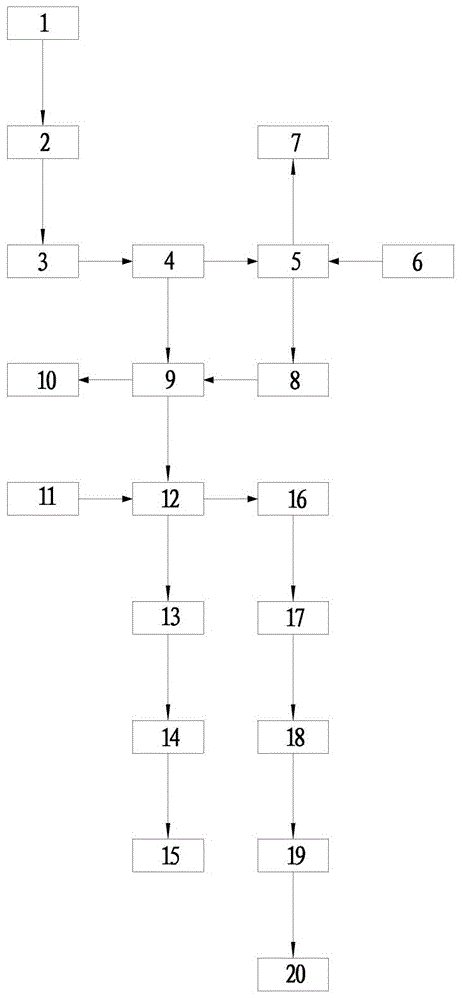

[0045] Below in conjunction with accompanying drawing, the technical method of the present invention is specifically described by example, so that understand the present invention better. All percentages mentioned herein are by mass unless otherwise stated.

example 1

[0047] A medium-temperature coal tar in northern Shaanxi, with a density of 1.042g / cm at 20°C 3 , the initial boiling point is 165°C, the final boiling point is 612°C, the sulfur content is 0.16%, and the nitrogen content is 1.2%.

[0048] The coal tar 1 is fractionated 2 by a coal tar fractionation tower to obtain a narrow distillate 3 at 165-300°C. Firstly, the narrow distillate oil is washed with 20% sodium hydroxide solution for dephenolization 4, the phenolic compounds in the distillate oil are changed into phenolic sodium salt, and then the phenolic sodium salt and dephenolic oil 9 are separated by using the density difference , sodium phenolate is decomposed by carbon dioxide to obtain pyridine-containing phenolic compounds, then use 80% phosphoric acid solution as solvent-6 to dehydrate and deslag-containing pyridine-containing phenolic compounds 5 at 1:12 (phosphoric acid solution and pyridine-containing The mass ratio of the phenolic compound) is used to extract the p...

example 2

[0051] A low-temperature coal tar from Xinjiang, density 0.97g / cm2 at 20°C 3 , the initial boiling point is 145°C, the final boiling point is 585°C, the sulfur content is 0.12%, and the nitrogen content is 0.94%.

[0052] The coal tar 1 is fractionated 2 by a coal tar fractionation tower to obtain a narrow distillate 3 at 145-280°C. Firstly, the narrow distillate oil is washed with 20% sodium hydroxide solution for dephenolization 4, the phenolic compounds in the distillate oil are changed into phenolic sodium salt, and then the phenolic sodium salt and dephenolic oil 9 are separated by using the density difference , sodium phenate is decomposed by carbon dioxide to obtain pyridine-containing phenolic compounds, then use 98% sulfuric acid solution as solvent-6 to dehydrate and deslag-containing pyridine-containing phenolic compounds 5 at 1:10 (sulfuric acid solution and pyridine-containing The mass ratio of the phenolic compound) is used to extract the pyridine compound, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com