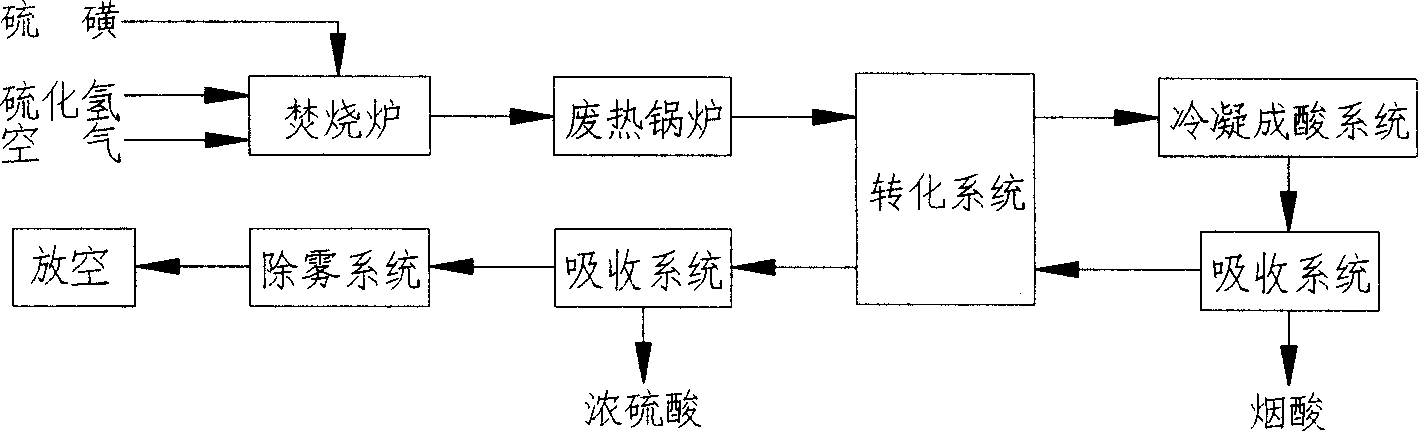

Combined dry and wet process of preparing high concentration sulfuric acid with hydrogen sulfide

A hydrogen sulfide, dry-wet technology, applied in sulfur trioxide/sulfuric acid and other directions, can solve the problems of difficult storage and transportation, high toxicity, etc., and achieve the effects of perfect treatment, improved conversion rate, and effective recovery of reaction heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Taking a 150kt / a hydrogen sulfide and sulfur combined acid production plant as an example, the dry and wet acid production process of the present invention will be described in detail.

[0033] Acid gas containing 30% hydrogen sulfide 5900Nm 3 / h, sent to the incinerator together with high-temperature liquid sulfur 3.622t / h mechanically atomized through the nozzle and purified air to produce SO 2 And water, other components in acid gas such as HCN, NH 3 、H 2 etc. burn in the incinerator to produce nitrogen oxides, CO 2 and moisture, in order to completely burn the acid gas, peroxygen combustion is adopted, and the combustion temperature is controlled below 1080°C.

[0034] The high-temperature reaction gas (containing sulfur dioxide, water and other components) coming out of the incinerator enters the conversion process and is converted into sulfur trioxide. In the dry-wet conversion process, the first three stages of the combined converter are wet conversion, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com