Combined chord measurement method for longitudinal irregularity of steel rail

A string measurement method and rail technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of high cost, complex price of inertial reference method detection and data processing systems, and inability to restore belt restoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

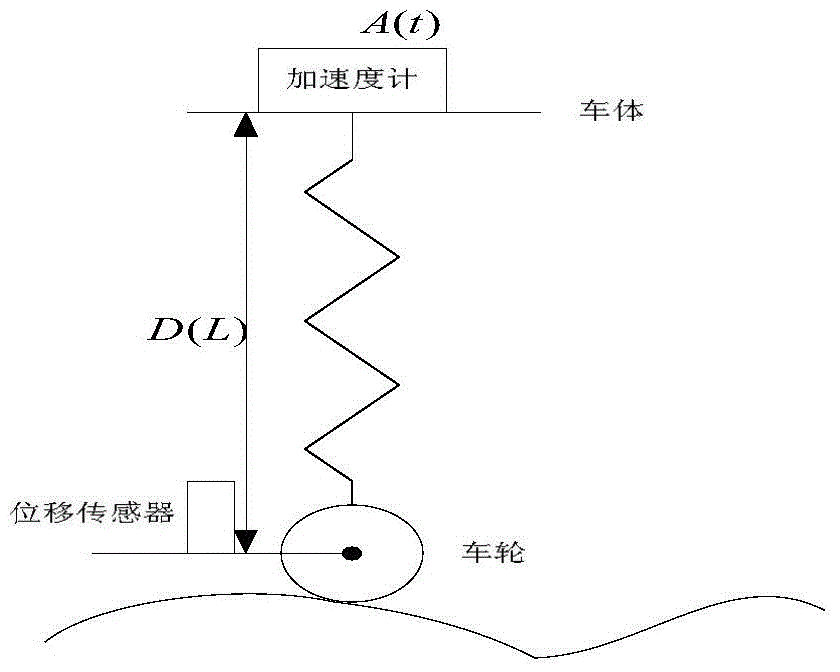

[0037] In order to avoid the situation caused by the installation method of the car body that the light is projected beyond the rail top when passing through the curve, the longitudinal height and irregularity detection system of the rail is placed on a detection trolley, which can carry out dynamic measurement of the irregularity along with the traction of the working vehicle. Fully improve work efficiency. The detection system is composed of mechanical support, high-precision 1D laser displacement sensor, concentrator, data acquisition system and other parts. The block diagram of the hardware system is as follows: Figure 4 shown.

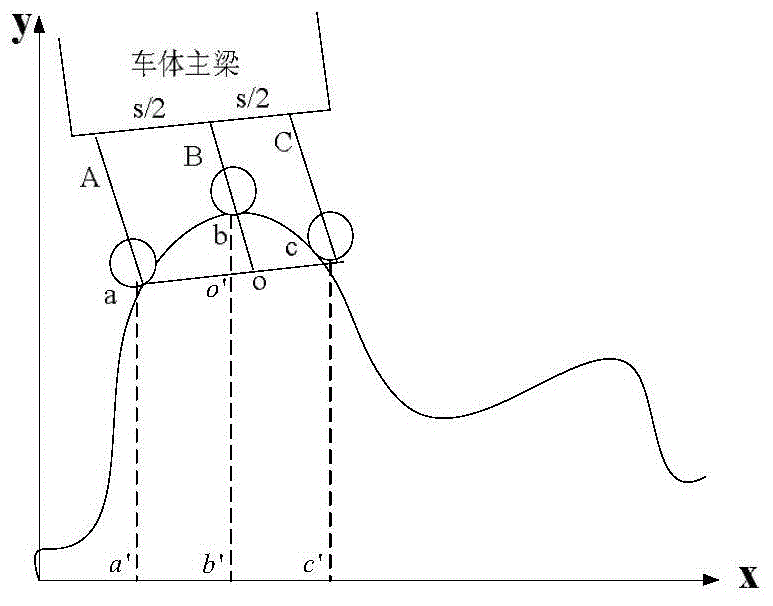

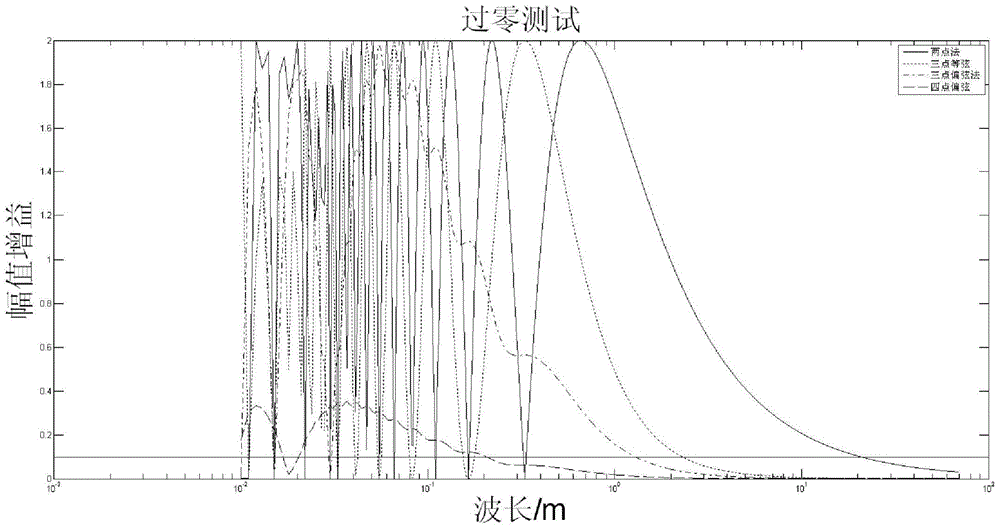

[0038] The detection system uses 2 groups of 6 high-precision 1-dimensional laser displacement sensors, 3 in each group, to complete the measurement of the longitudinal height and unevenness of one side of the rail. The same group of 3 sensors is placed in a mounting box, the incident point of the light source is on a line, and the incident ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com