Wavelength calibration method of optical spectrum instruments

A spectrum and instrument technology, applied in the field of wavelength calibration of spectroscopic instruments, can solve the problems of spectral image skew, wavelength accuracy limitation, and limited spectral image sampling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

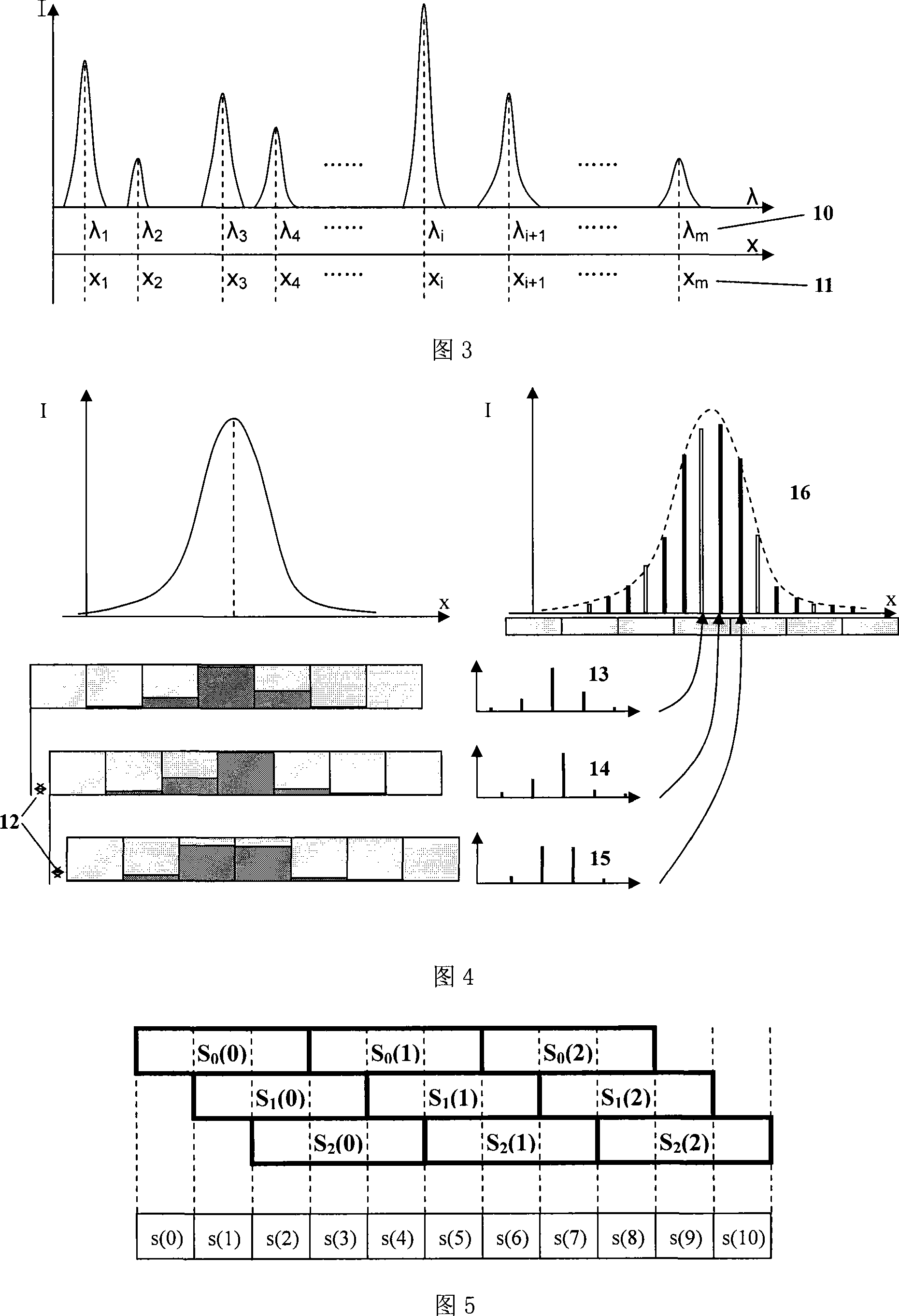

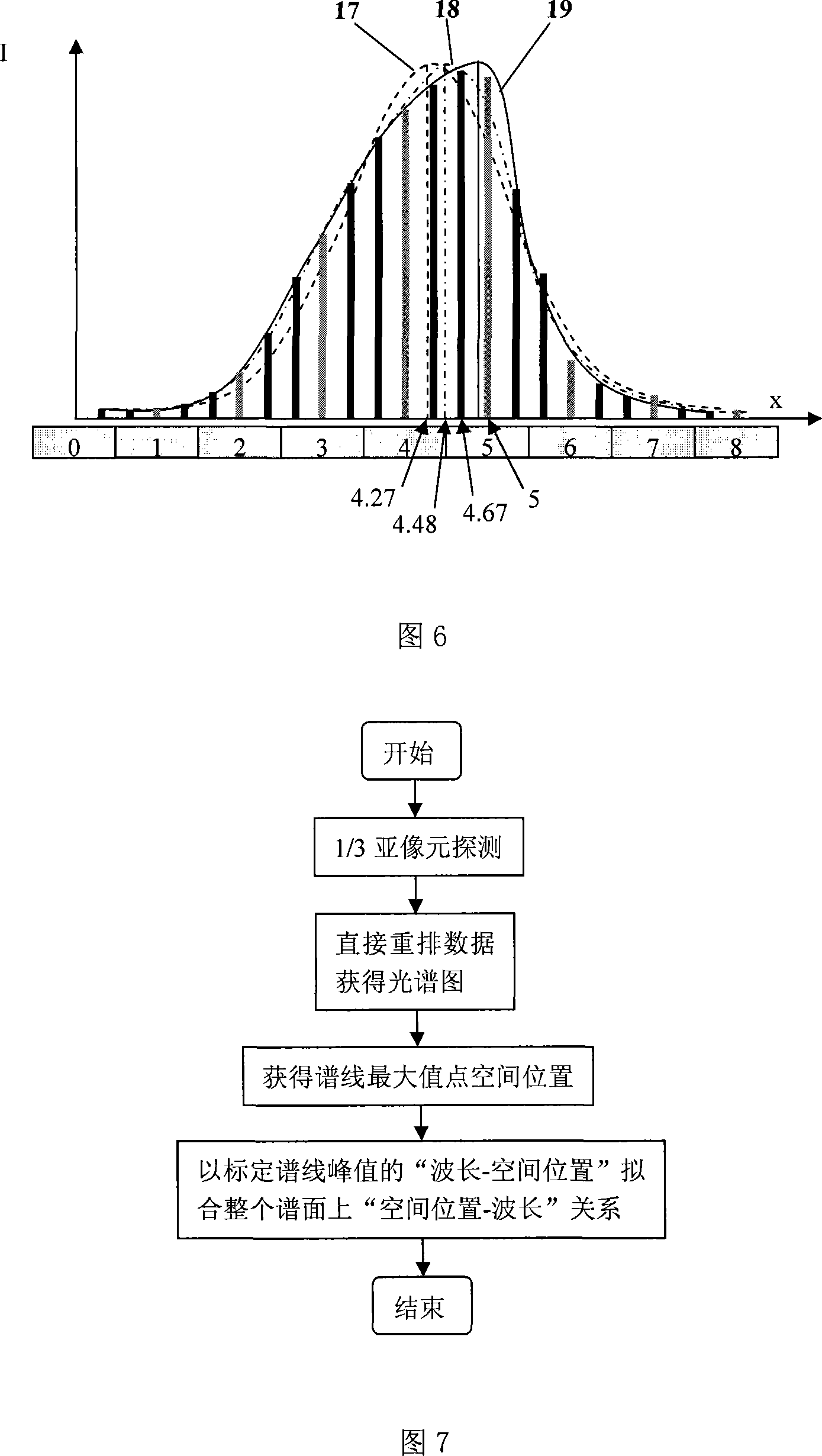

[0026] In the new wavelength calibration method according to this patent, a fixed spectral image is used, and the detector is moved at a step distance of 1 / 3 pixel to realize 1 / 3 sub-pixel detection; the data is directly rearranged to reconstruct the spectral map; the spatial position of the spectral peak It is represented by the sub-pixel position of the maximum point of each spectral line data in the reconstructed spectrogram. The specific flow chart is shown in Figure 7.

[0027] Table 1 shows the comparison of the wavelength accuracy at some spectral lines under a set of experimental results and the wavelength accuracy under the existing method. Compared with the wavelength accuracy of existing methods, the wavelength accuracy of the new method is improved by about 30% on average.

[0028] Table 1. Comparison of the wavelength accuracy of the calibration results between the existing method and the new method of Example 1 (unit: nm)

[0029] Detection line wavele...

Embodiment 2

[0031] In the new wavelength calibration method according to this patent, fixed detectors and rotating gratings are used to move the spectral image relative to the detector by 1 / 3 pixel interval to achieve 1 / 3 sub-pixel detection; the average band-limited recursion is used to obtain sub-pixels The detection value reconstructs the spectrogram; the spatial position of the spectral peak is represented by the spatial position corresponding to the maximum value after Gaussian fitting of the spectral line profile. The specific flow chart is shown in Figure 8.

[0032] Table 2 shows the comparison of the wavelength accuracy at some spectral lines under a set of experimental results and the wavelength accuracy under the existing method. Compared with the wavelength accuracy of existing methods, the wavelength accuracy of the new method is improved by about 80%.

[0033] Table 2. Comparison of the wavelength accuracy of the calibration results between the existing method of Example 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com