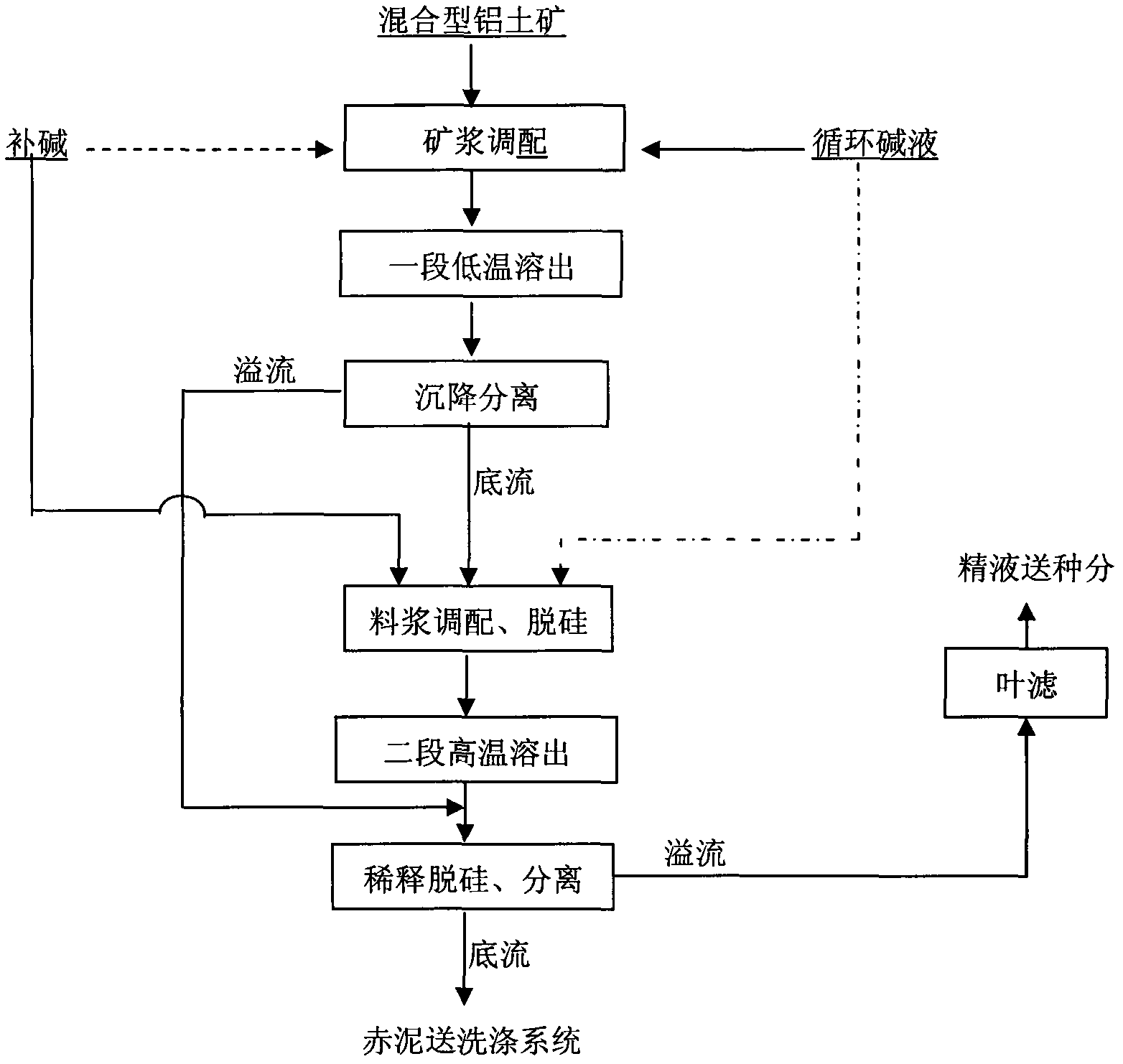

Two-stage digestion process of boehmite-gibbsite hybrid bauxite

A gibbsite and boehmite technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of the decrease of alumina recovery rate, the increase of red mud amount and the high concentration of solution, so as to reduce the energy consumption of dissolution and reduce the Loss, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The boehmite-gibbsite mixed type bauxite with an aluminum-silicon ratio (A / S) of 6 is used as a raw material, wherein the boehmite mineral weight percentage accounts for 20%. The molecular ratio of most of the circulating lye to this mixed bauxite is 1.38, and the concentration of lye is Na 2 O 130g / L, eluted at 110°C for 20min, the caustic molecular ratio of the first-stage eluate is 1.40. Add caustic soda and the remaining circulating lye to the underflow of a section of dissolved ore pulp settling and separation, according to the concentration of ore pulp Na 2 O 183g / L, and the molecular ratio of boehmite dissolved in the underflow is 1.37 for pulp preparation. The prepared pulp is pre-desiliconized at 100°C for 6 hours, and the pre-desiliconization rate is 50%. The pre-desilication slurry is directly subjected to the second-stage high-temperature dissolution, the dissolution temperature is 230°C, the dissolution time is 20min, the caustic molecular ratio of the se...

Embodiment 2

[0022] The processing of raw materials and a section of low-temperature stripping are the same as in Example 1. Add caustic soda and the remaining circulating lye to the underflow of a section of dissolved ore pulp settling and separation, according to the concentration of ore pulp Na 2 O 150g / L, and the molecular ratio of boehmite dissolved in the underflow is 1.33 for pulp preparation. The prepared pulp was pre-desiliconized at 100°C for 6 hours, and the pre-desiliconization rate was 46%. The pre-desilication slurry is directly subjected to the second-stage high-temperature dissolution, the dissolution temperature is 230°C, the dissolution time is 20min, and the caustic molecular ratio of the second-stage dissolution liquid is 1.35. The second-stage high-temperature dissolution slurry is mixed with the overflow of the first-stage low-temperature dissolution pulp sedimentation separation, and is diluted and desiliconized at 100°C for 2 hours, and then the slurry is separated...

Embodiment 3

[0024] Processing raw material is with embodiment 1. The molecular ratio of circulating lye and mixed bauxite according to the complete dissolution of gibbsite is 1.38, and the concentration of lye is Na 2 O 180g / L, dissolved at 100°C for 20 minutes, the caustic molecular ratio of the eluate in the first stage is 1.40. Add caustic soda to the underflow of a section of dissolved ore pulp settling and separation, according to the concentration of Na in the pulp 2O 240g / L, and the molecular ratio of boehmite dissolved in the underflow is 1.30 for pulp preparation. The prepared pulp is pre-desiliconized at 95°C for 8 hours, and the pre-desiliconization rate is 40%. The pre-desilication slurry is directly subjected to the second-stage high-temperature dissolution, the dissolution temperature is 230°C, the dissolution time is 10min, and the caustic molecular ratio of the second-stage dissolution liquid is 1.32. The second-stage high-temperature dissolution slurry is mixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com