Integrated carbon and nitrogen removal bioreactor

A technology of bioreactors and reactors, applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc., can solve the problems of large footprint, high energy consumption, and high cost, and achieve small footprint , Low operating costs, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

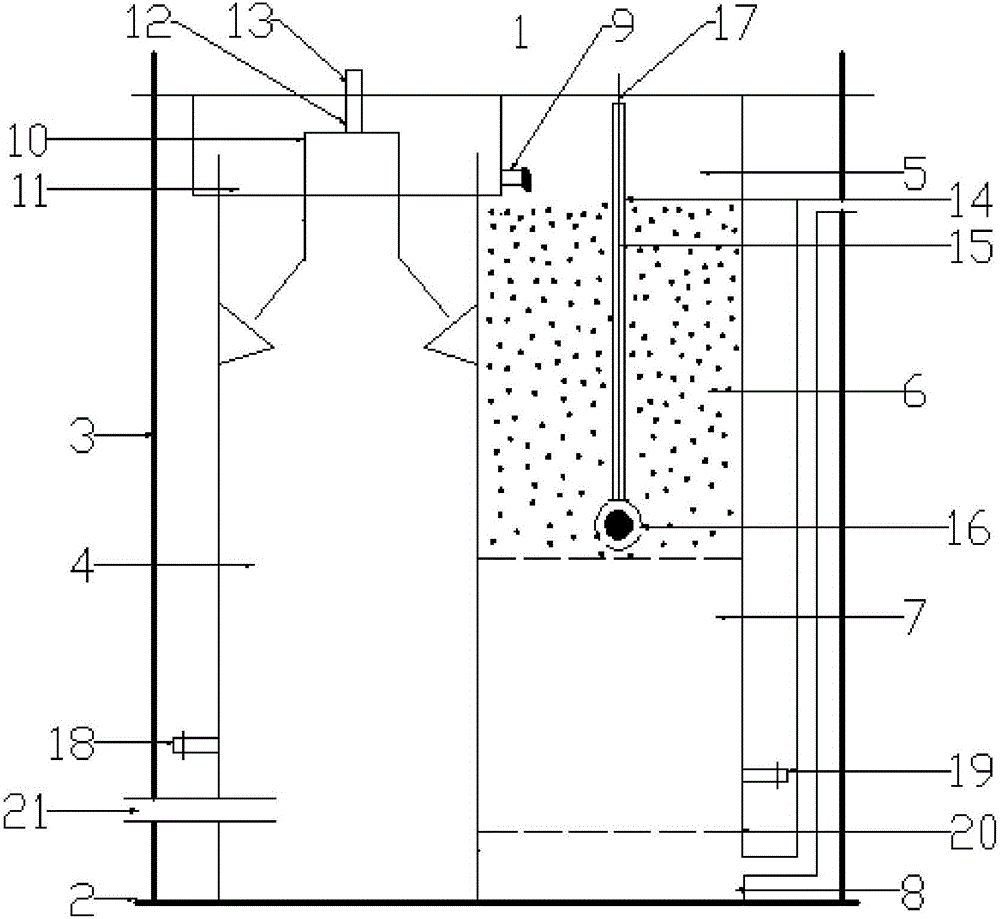

[0016] Further illustrate the present invention below in conjunction with accompanying drawing

[0017] Referring to the attached picture:

[0018] An integrated carbon and denitrification bioreactor according to the present invention includes a reactor body 1, a base 2, a bracket 3 arranged on the periphery of the reactor body 1, a water outlet main pipe, and a water inlet main pipe for communicating with external water sources , the reactor body 1 and the bracket 3 are installed on the base 2, the water inlet main pipe and the water outlet main pipe are erected on the bracket 3, and the reactor The inner cavity of the body 1 is separated into an independent first cavity and a second cavity by a vertical partition, and the first cavity and the second cavity are communicated through the second water inlet pipe 9; the first cavity is used for filling Anaerobic digestion unit 4 for anaerobic granular sludge; the second chamber is sequentially divided from top to bottom into a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com