Full-recovery shield tunnel enter and exit water stop device

A technology of water stop device and access hole, which is applied in shaft equipment, wellbore lining, tunnel lining, etc. It can solve the problems of not meeting construction conditions and anti-risk requirements, high requirements for ring pipe processing and embedding, and increased difficulty in construction operations, etc. , to achieve the effects of simple structure, improved construction efficiency, and convenient overall assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

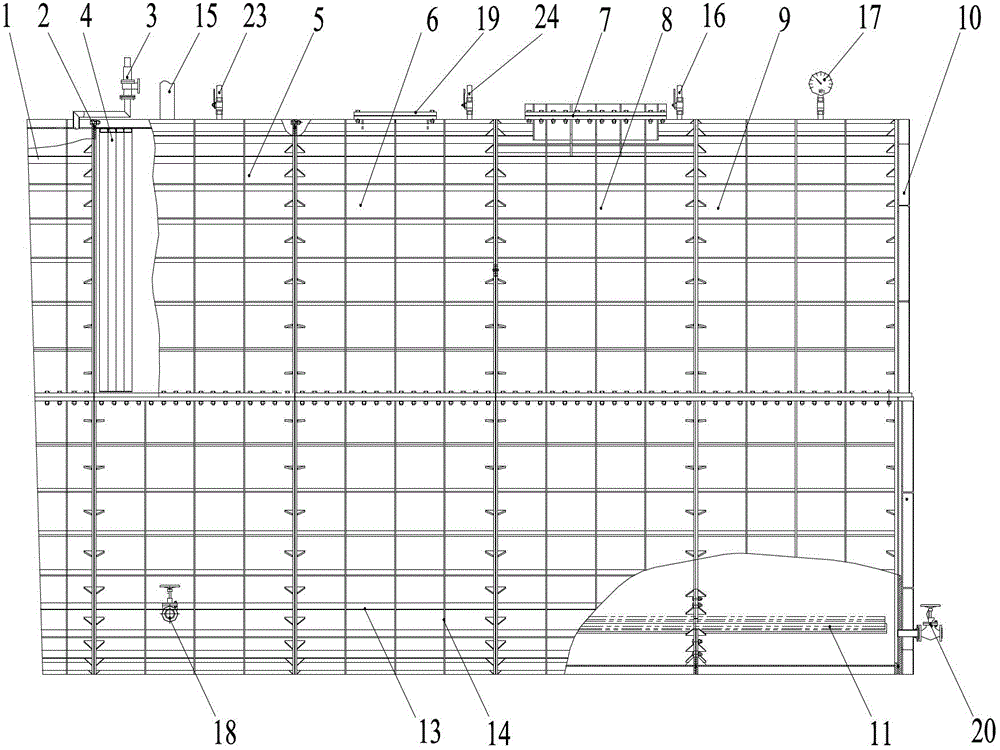

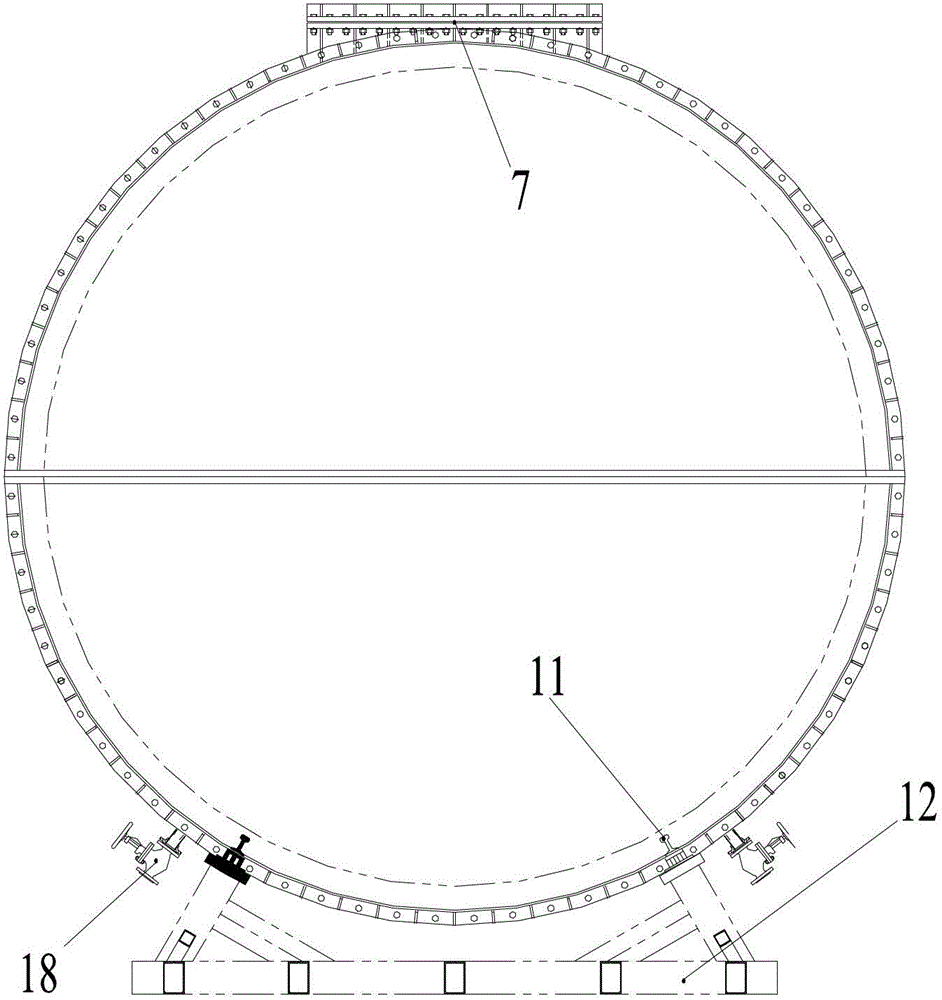

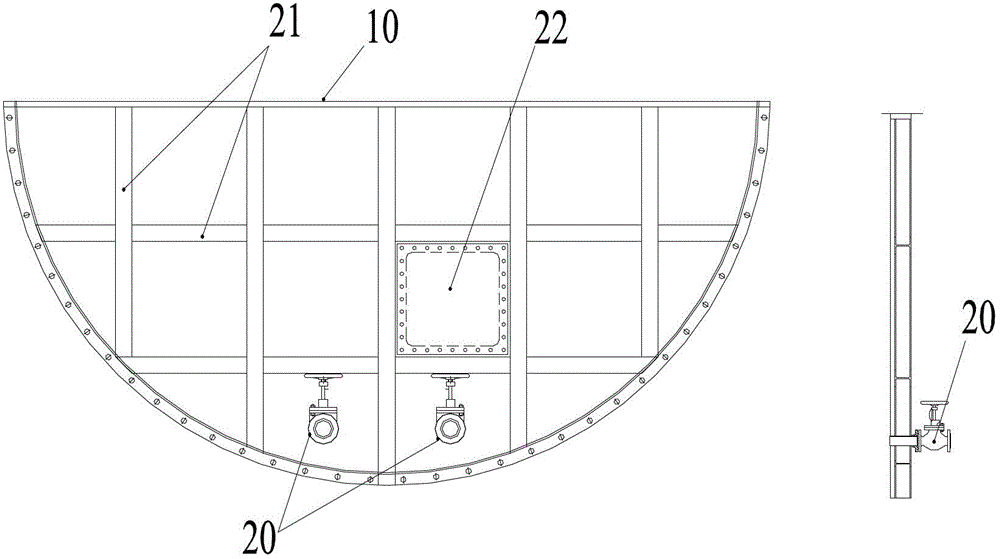

[0028] As a water stop device for the exit of the shield tunnel.

[0029] Step 1: Install the base 12 of the device. During the installation process of the device, a steel pad is used to level the base 12 and the standard cylinder group, so that the axes of the cylinders of the whole device are consistent.

[0030] The second step: air bag installation and grouting pipe installation. Install a circle of airbags in the hole close to the ground wall, and weld a circle of patterned steel plates on the outside of the airbags to narrow the gap between the hole circle and the shield; insert grouting pipes at the seams of the airbags to It is used for blocking the hole door.

[0031] The third step: installation of the transition cylinder 1 and the first standard cylinder 5 . Assemble the transition cylinder 1 and the first standard cylinder 5 on the ground, and the assembly adopts a horizontal assembly method. The specific method is to firstly assemble the upper and lower half cy...

Embodiment 2

[0036] Receive water stop device as shield tunneling.

[0037] Step 1: Install the base 12 of the device. During the installation process of the device, a steel pad is used to level the base 12 and the standard cylinder group, so that the axes of the cylinders of the whole device are consistent.

[0038] The second step: pre-cutting the door. The thickness of the connecting wall of the shield working well is 1.2m, and the shield is placed on the underground diaphragm wall, and the 80cm thick underground diaphragm wall is first cut out.

[0039] The third step: air bag installation and grouting pipe installation. Install a circle of airbags in the hole close to the ground wall, and weld a circle of patterned steel plates on the outside of the airbags to narrow the gap between the hole circle and the shield; insert grouting pipes at the seams of the airbags to It is used for blocking the hole door.

[0040] Step 4: Install the transition cylinder 1 and the first standard cyl...

Embodiment 3

[0046] As a water stop device for the exit of the shield tunnel.

[0047] Step 1: Install the base 12 of the device. During the installation process of the device, a steel pad is used to level the base 12 and the standard cylinder group, so that the axes of the cylinders of the whole device are consistent.

[0048] The second step: air bag installation and grouting pipe installation. Install a circle of airbags in the hole close to the ground wall, and weld a circle of patterned steel plates on the outside of the airbags to narrow the gap between the hole circle and the shield; insert grouting pipes at the seams of the airbags to It is used for blocking the hole door.

[0049] The third step: installation of the transition cylinder 1 and the first standard cylinder 5 . Assemble the transition cylinder 1 and the first standard cylinder 5 on the ground, and the assembly adopts a horizontal assembly method. The specific method is to firstly assemble the upper and lower half cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com