Air compressor residual-heat utilization system and method

A technology of air compressors and heat exchange systems, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., which can solve the problems of incomplete utilization of waste heat of air compressor waste heat utilization equipment, so as to improve efficiency and application Range, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

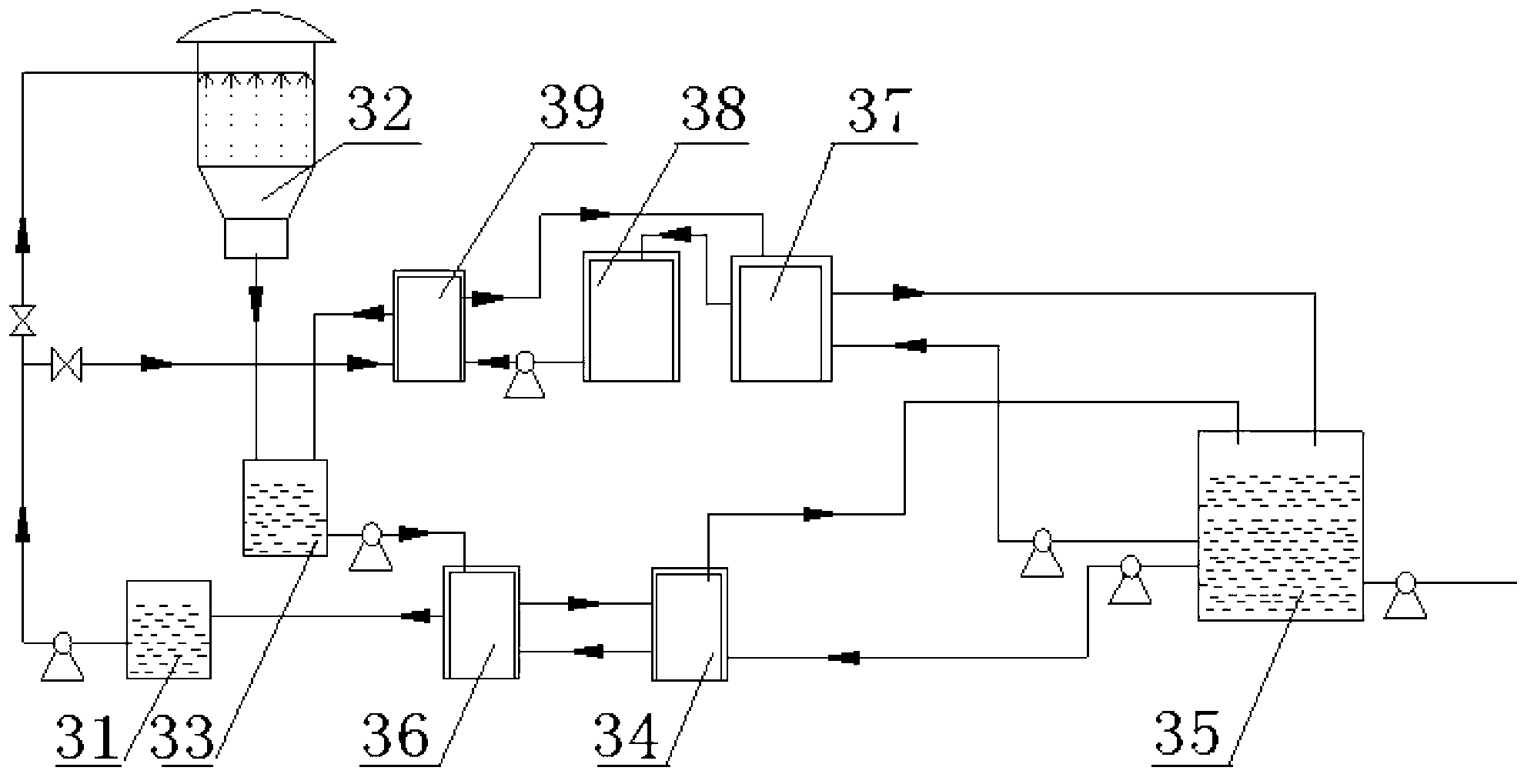

[0056] image 3 It is a structural schematic diagram of the air compressor waste heat utilization system of the present invention.

[0057] This embodiment provides an air compressor waste heat utilization system, such as image 3 As shown, it includes a water storage tank 35, a computer control system, a first heat exchange system and a second heat exchange system that respectively realize heat exchange with an air compressor;

[0058] The computer control system is electrically connected with the water storage tank, the first heat exchange system and the second heat exchange system, and is used to realize the automatic monitoring and computer management of the water storage tank, the first heat exchange system and the second heat exchange system;

[0059] The air compressor 36 is two sets of screw air compressors and four centrifugal air compressors arranged side by side; the primary cooler of the screw air compressor is provided with a water cooling device; the primary coo...

Embodiment 2

[0086] The air compressor waste heat utilization method disclosed in this embodiment takes the air compressor waste heat utilization system shown in Embodiment 1 as an example, and the air compressor is a screw air compressor and a centrifugal air compressor connected in parallel.

[0087] Before the air compressor is running, the water in the storage tank is pumped from the cold fluid inlet of the air compressor waste heat recycling device into the air compressor waste heat recycling device;

[0088] When the air compressor is running, the water in the cold water pool enters the water cooling device through the cold fluid inlet of the water cooling device, and is combined with the primary cooler of the screw air compressor and / or the primary cooler of the centrifugal air compressor and / or the centrifugal air compressor. The secondary cooler of the air compressor exchanges heat; the temperature of the water from the cold water pool increases after heat exchange and enters the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com