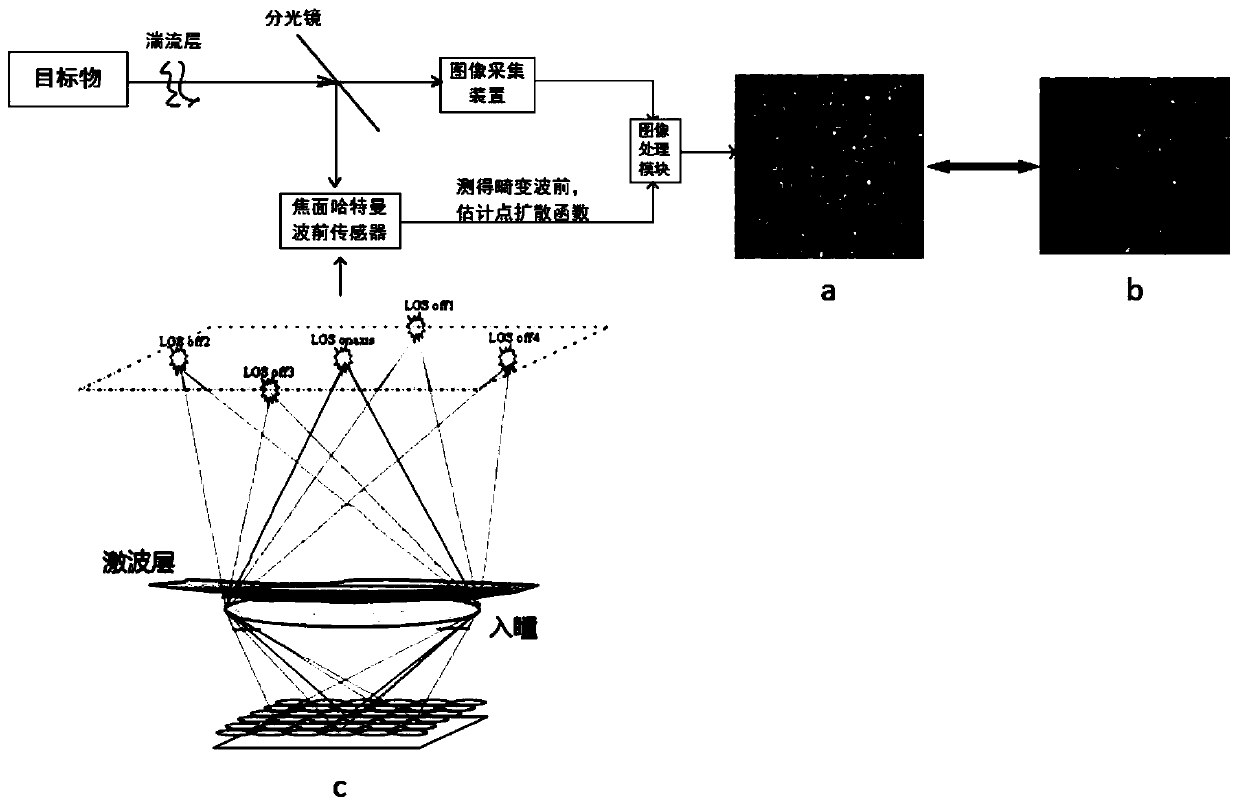

Large field of view image sharpening device and method based on focal plane Hartmann wavefront sensor

An image acquisition device and sensor technology, which is applied in the field of image processing, can solve problems such as not being able to meet the application requirements of large field of view images, and achieve the effect of increasing the image restoration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

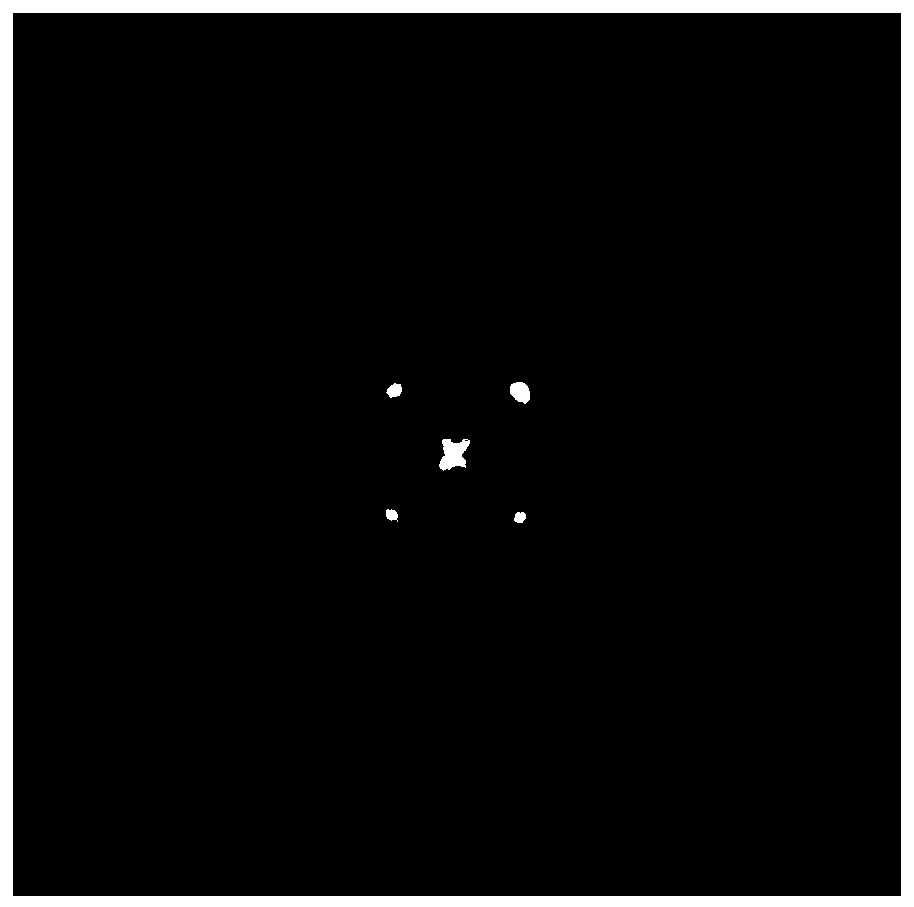

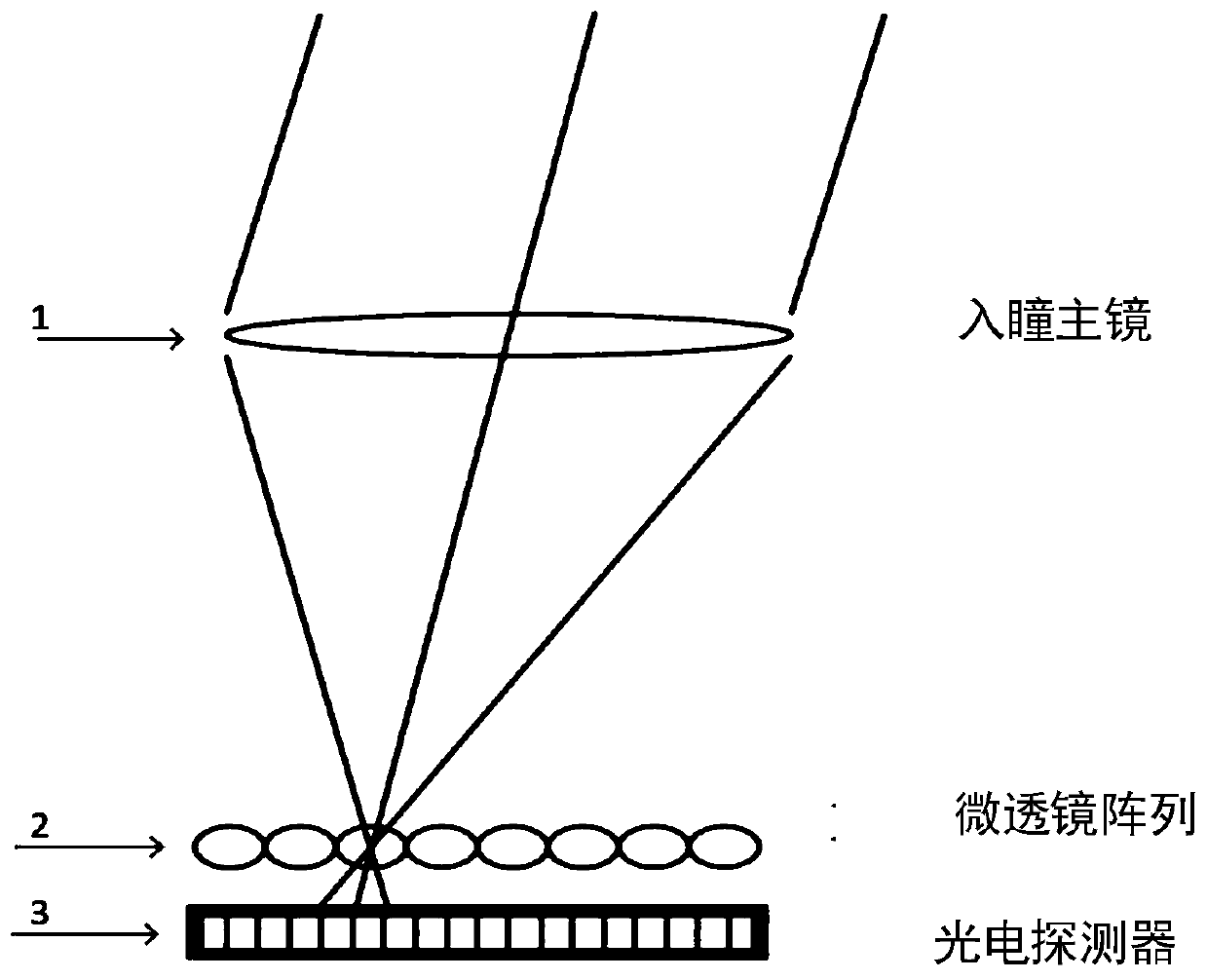

[0031] like image 3 As shown, the structure of the focal plane Hartmann wavefront sensor of the present invention is to place a microlens array on the focal plane of the entrance pupil primary mirror, place an array type photodetector on the focal plane of the microlens array, and the microlens array is to The complex amplitude of the light at the focal plane of the entrance pupil is divided into the light field, and each microlens forms a low-resolution image of the observation target at the detector, that is, a spot array is formed.

[0032] Technical steps of the present invention are specifically as follows:

[0033] Step S1: Use an aberration-free ideal planar light source to calibrate the microlens array and the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com