System and method used for preparing glycol via hydrogenation of oxalic ester

An oxalate and ethylene glycol technology, applied in chemical instruments and methods, hydroxyl compound preparation, sustainable manufacturing/processing, etc., to reduce system energy consumption, avoid heat exchange, and improve reaction yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

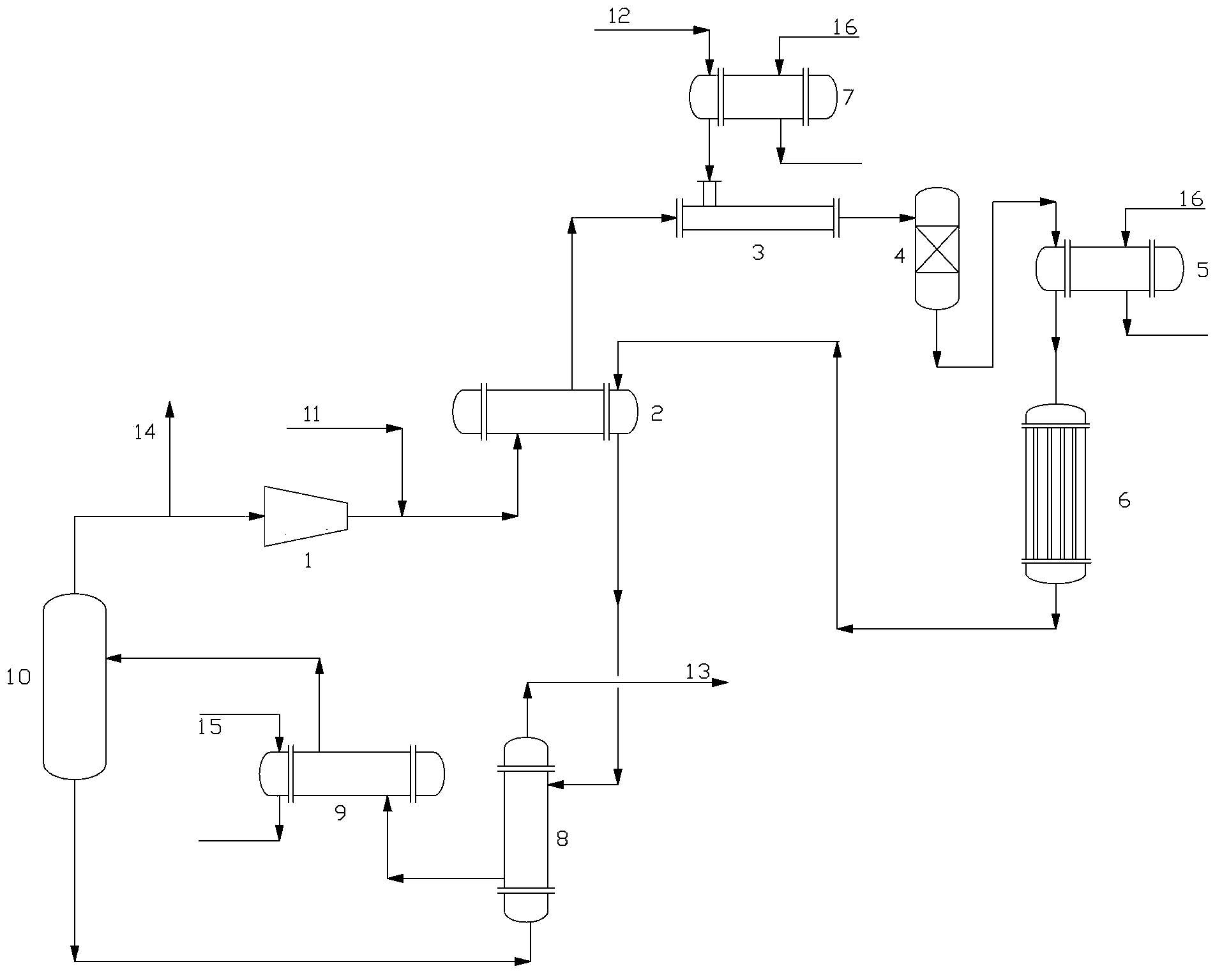

[0061] Such as figure 1 As shown, a system for hydrogenating oxalate to ethylene glycol includes: circulating hydrogen compressor 1, inlet and outlet heat exchanger 2, mixer 3, feed guard bed 4, circulating hydrogen heater 5, hydrogenation Reactor 6, raw material preheater 7, reaction product intermediate heat exchanger 8, reaction discharge cooler 9 and gas-liquid separation tank 10;

[0062] The inlet and outlet heat exchanger 2 is sequentially connected to the mixer 3, the feed guard bed 4 and the circulating hydrogen heater 5, the raw material preheater 7 is connected to the mixer 3; the outlet of the circulating hydrogen heater 5 is connected to the inlet of the hydrogenation reactor 6, and the hydrogen gas enters The material 11 enters the hydrogenation reactor 6 through the inlet and outlet heat exchanger 2, the mixer 3, the feed guard bed 4 and the circulating hydrogen heater 5; Material guard bed 4;

[0063] The outlet of the hydrogenation reactor 6 is sequentially ...

Embodiment 2

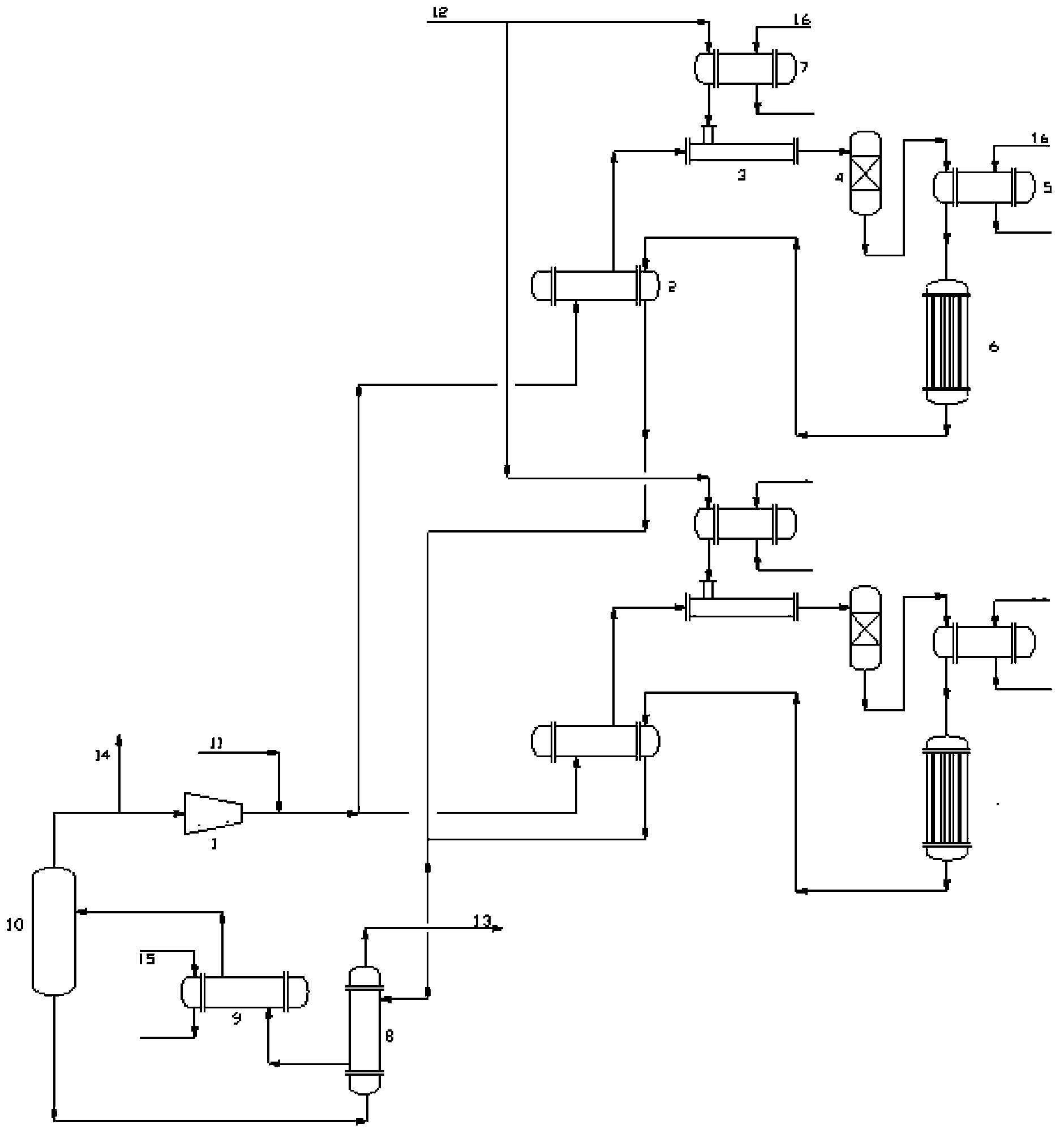

[0078] The system is the same as in Example 1, the difference is only that the inlet and outlet heat exchanger 2, the mixer 3, the circulating hydrogen heater 5, and the hydrogenation reactor 6 are two in parallel: as figure 2 shown.

[0079] Using oxalate ester hydrogenation catalyst, the catalyst weight space velocity is 0.1~0.5h -1 , The maximum temperature rise of the bed is less than 10°C.

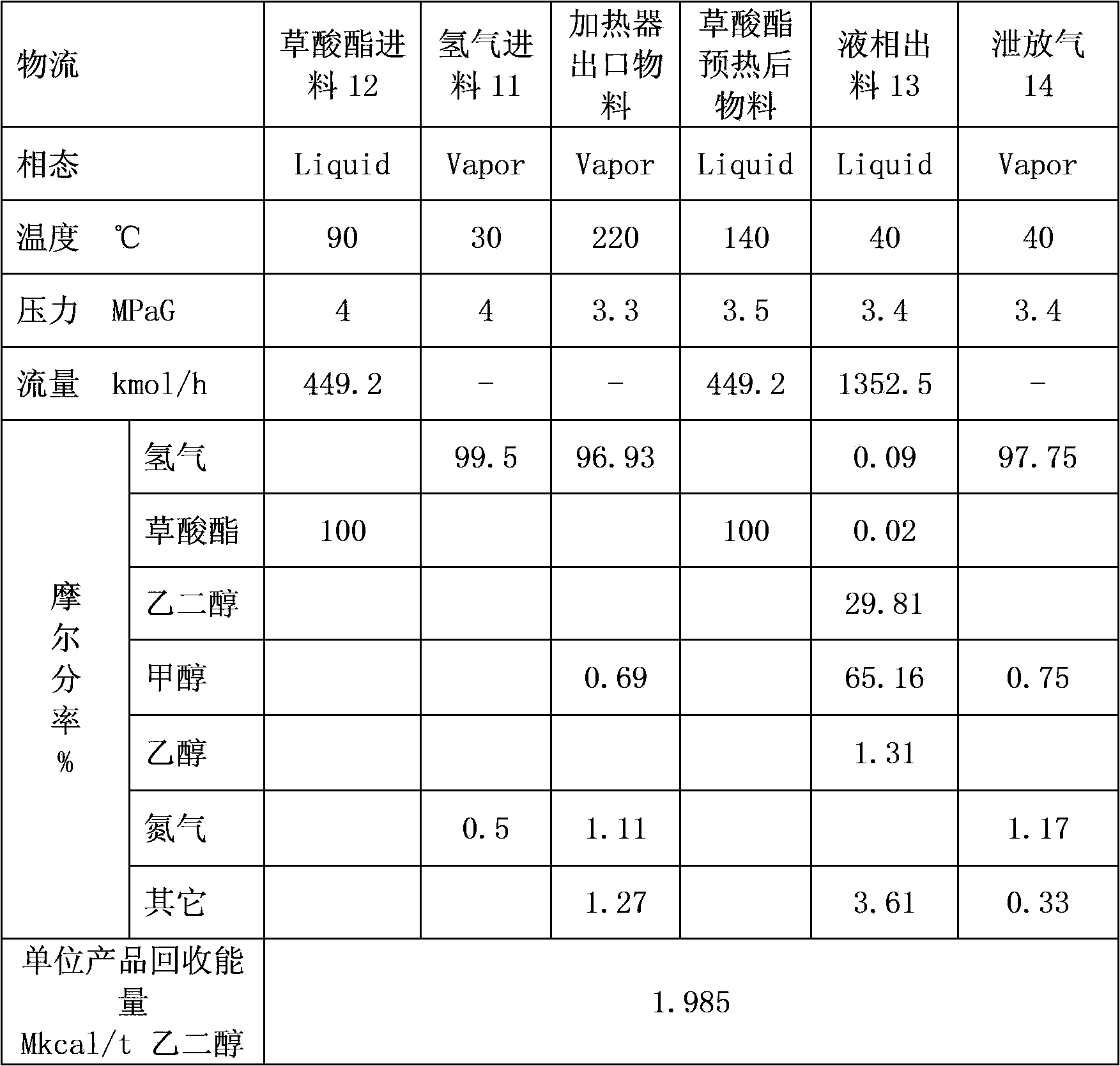

[0080] use as figure 2 Shown flow process, obtain the result of table 2.

[0081] The results show that, adopting the system and method of the present invention to prepare ethylene glycol, the maximum temperature rise of the isothermal reactor bed can be controlled within 10°C, the conversion rate of oxalate is greater than 98%, and the selectivity of ethylene glycol is greater than 90mol%. The heat removal and heat exchange network recovers energy, and the recovered energy is 1.985Mkcal / t ethylene glycol.

[0082] Table 2

[0083]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com