Spice for cigarettes and application thereof

A technology of tobacco spices and material ratio, which is applied in the fields of application, essential oils/flavors, tobacco, etc., to achieve obvious effects, simple and applicable process, and improve the effect of fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

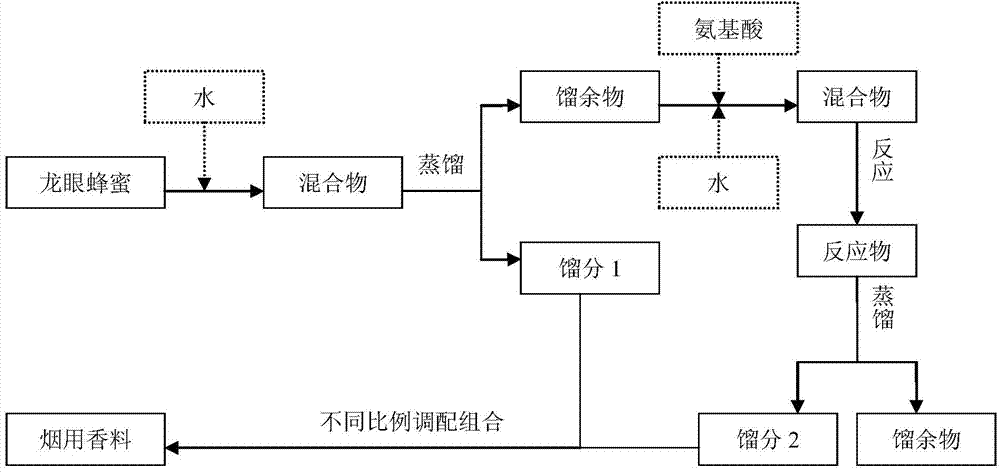

Method used

Image

Examples

Embodiment 1

[0028] Add 1L of deionized water into a constant temperature water bath, keep the temperature of the water bath at 60°C, feed longan honey and water at a ratio of 1:0.5 (g:mL), add longan honey while stirring, and control the stirring at 100rpm / min. After adding the longan honey, heat up the temperature to 90°C. At this time, a large amount of foam will be generated. After the foam is condensed, the heating rate will be increased to collect fractions. When the fractions are collected to 20% of the honey weight, stop collecting. a distillate. Add 10% glycine by weight of longan honey and 1 times the weight of water to the distillate, and react at 100°C for 1 hour to obtain the distillate Maillard reaction product. Add 1L of deionized water to a constant temperature water bath, and keep the water temperature at 65°C. ℃, the prepared distillate Maillard reactant and water are fed according to the ratio of 1: 0.5 (g:mL), and the distillate Maillard reactant is added while stirring...

Embodiment 2

[0030] Add 1L of deionized water into a constant temperature water bath, keep the temperature of the water bath at 70°C, feed longan honey and water at a ratio of 1:2 (g:mL), add longan honey while stirring, and control the stirring at 300rpm / min. After adding the longan honey, heat up the temperature to 95°C. At this time, a large amount of foam will be generated. After the foam is condensed, the heating rate will be increased to collect fractions. When the fractions are collected to 30% of the honey weight, stop collecting. a distillate. The distillate adds the water of longan honey weight 15%% alanine and 2 times of weight, reacts 3h at 105 ℃, obtains the distillate Maillard reactant, 1L deionized water is joined in the constant temperature water bath, constant The water temperature is 75°C, the prepared distillate Maillard reactant and water are fed according to the ratio of 1:2 (g:mL), and the distillate Maillard reactant is added while stirring. The stirring speed is 200...

Embodiment 3

[0032] Add 1L of deionized water into a constant temperature water bath, keep the temperature of the water bath at 65°C, feed longan honey and water at a ratio of 1:1 (g:mL), add longan honey while stirring, and control the stirring at 200rpm / min. After the longan honey is added, heat up the temperature to 95°C. At this time, a large amount of foam will be generated. After the foam is condensed, the heating rate will be increased, and the fraction will be collected. When the fraction reaches 25% of the honey weight, stop collecting, and the second product will be obtained. a distillate. Add 10% L-glutamic acid of longan honey weight and 1.5 times of weight water to the distillate, and react for 2 hours at 102°C to obtain the distillate Maillard reaction product, and add 1L of deionized water to a constant temperature water bath , constant water temperature 75 ℃, the distillate Maillard reactant and water prepared according to the ratio of 1:1 (g:mL) feed intake, add the distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com