Method for simultaneously preparing indocalamus leaf volatile oil, total flavone and total polysaccharide

A technology of volatile oil and total flavonoids is applied in the field of biological active ingredients, which can solve the problems of single extraction, high extraction cost, low resource utilization rate, etc., and achieve the effects of avoiding resource waste, reducing cost and improving resource utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

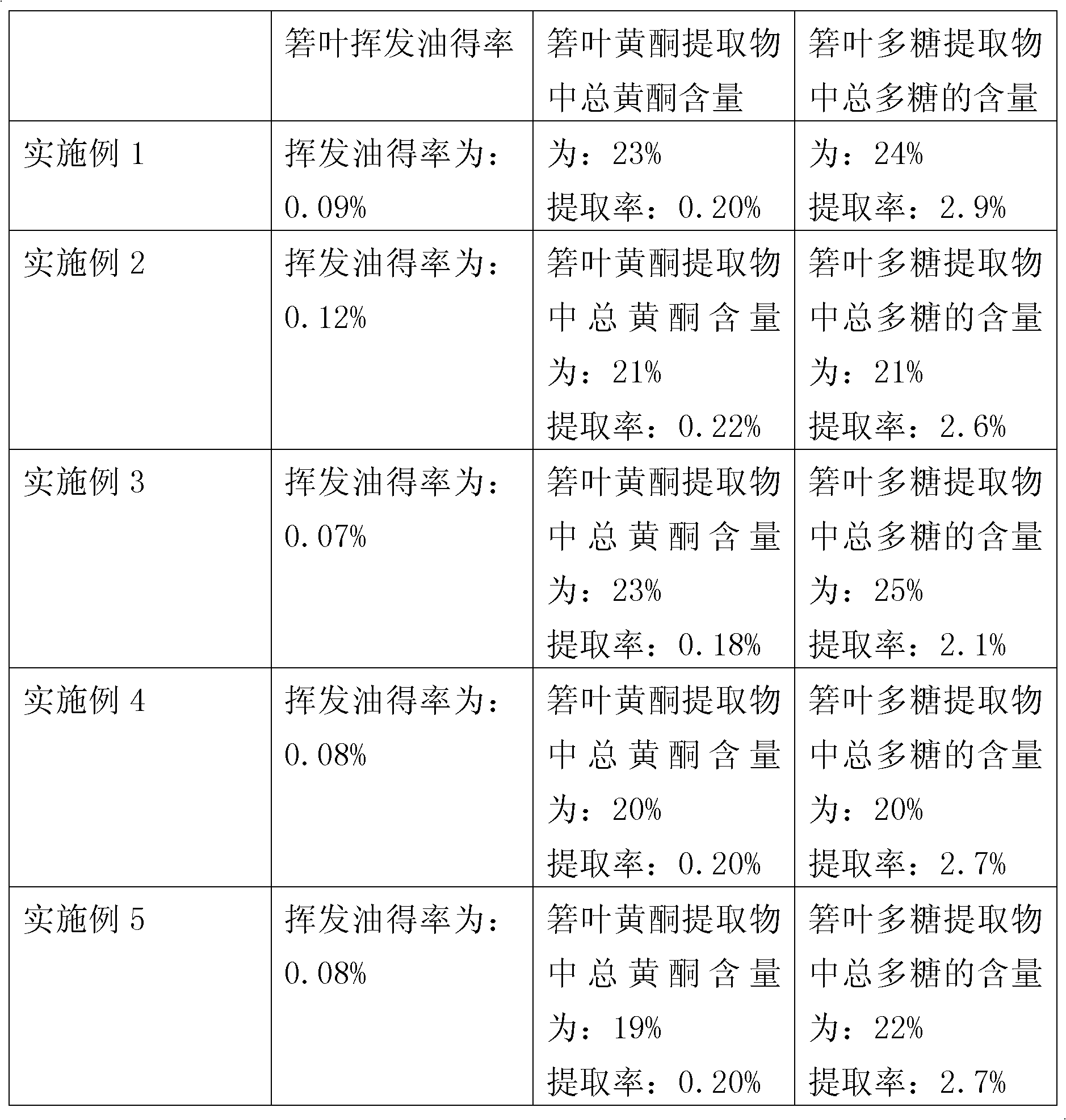

Embodiment 1

[0027] Take 2 kg of Ruoye leaf powder, add 8 times the amount of water, soak for 2 hours, extract by steam distillation for 7 hours, and obtain volatile oil; after extracting the volatile oil, keep the medicinal solution, add 9 times the amount of crude drug to the medicinal residue, and extract 30% ethanol under reflux time, each time 1.0h, filter, after extracting liquid decompression recovery ethanol, combine each extracting liquid and medicinal liquid after extracting volatile oil, decompress and concentrate, obtain extract, add water to disperse and dissolve, make the concentration of loading sample liquid in terms of crude drug amount 0.7g / ml, passed through the AB-8 macroporous resin, the adsorption flow rate was 2BV / h, and the diameter-height ratio of the resin column was 1:6. Precipitate and dry to obtain the total polysaccharide extract of Ruoye leaves; then elute 3BV with 70% ethanol at an elution flow rate of 1.5BV / h, concentrate the eluate and dry to obtain the tot...

Embodiment 2

[0029] Take 5 kg of Ruoye leaf powder, add 5 times the amount of water, soak for 4 hours, extract by steam distillation for 12 hours, and obtain the volatile oil; after extracting the volatile oil, keep the medicinal liquid for use, add the dregs to 12 times the amount of the crude drug, and extract with 40% ethanol under reflux for 3 time, each time 1.5h, filter, after extracting liquid decompression recovery ethanol, combine each extracting liquid and medicinal liquid after extracting volatile oil, decompress and concentrate, obtain extract, add water to disperse and dissolve, make the concentration of loading sample liquid in terms of crude drug amount It is 1.0g / ml, through HP-20 macroporous resin, the adsorption flow rate is 3BV / h, and the resin column diameter-to-height ratio is 1:8. Precipitate and dry to obtain the total polysaccharide extract of Ruoye leaves; then elute 4BV with 70% ethanol at an elution flow rate of 2BV / h, concentrate the eluate and dry to obtain the ...

Embodiment 3

[0031] Take 2kg of Ruoye leaf powder, add 12 times the amount of water, soak for 0h, extract by steam distillation for 4h, and obtain the volatile oil; after extracting the volatile oil, keep the medicinal liquid for use, add the dregs to 6 times the amount of the crude drug, and extract 30% by reflux with 40% ethanol time, each time 1.0h, filter, after extracting liquid decompression recovery ethanol, combine each extracting liquid and medicinal liquid after extracting volatile oil, decompress and concentrate, obtain extract, add water to disperse and dissolve, make the concentration of loading sample liquid in terms of crude drug amount 0.8g / ml, passed through D-101 macroporous resin, the adsorption flow rate was 2BV / h, and the resin column diameter-to-height ratio was 1:7. Precipitate and dry to obtain the total polysaccharide extract of Ruoye leaves; then elute 3BV with 70% ethanol at an elution flow rate of 1BV / h, concentrate the eluate and dry to obtain the total flavonoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com