Low temperature adsorption method for continuously producing ultra-pure gas

A production method and low-temperature technology, applied in the field of ultra-pure gas production by low-temperature adsorption method, can solve the problems of large loss of liquid nitrogen, difficulty in large-scale production, continuous production, complicated operation process, etc., so as to reduce regeneration operation and cooling loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following takes the preparation of hydrogen as an example to describe in detail, but the present invention can be applied to the preparation of ultrapure gases such as hydrogen, deuterium, tritium, helium, neon, argon, nitrogen, oxygen, carbon monoxide or methane.

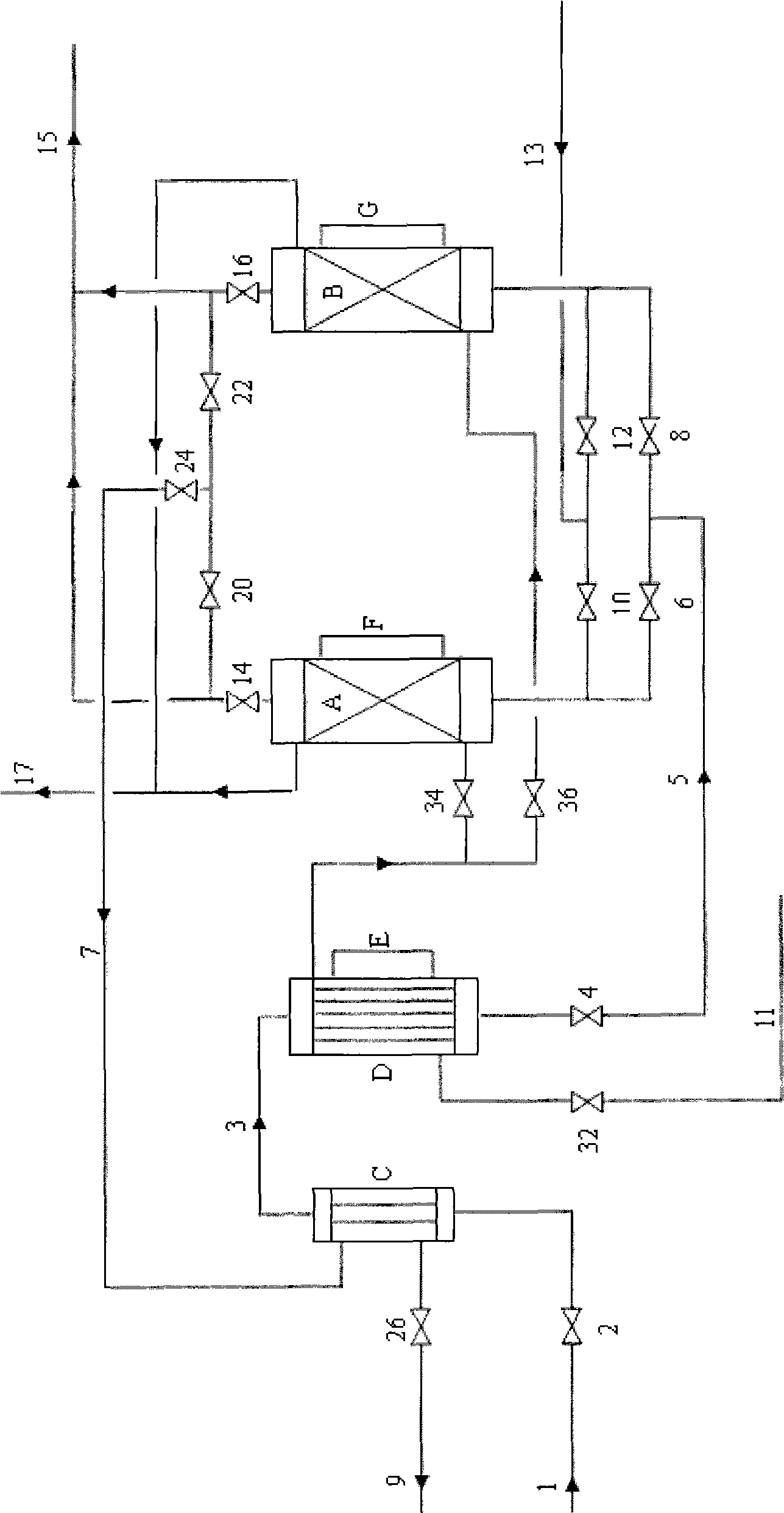

[0024] The raw material hydrogen is electrolytic hydrogen or industrial hydrogen containing low-boiling impurities such as nitrogen, oxygen, argon, carbon monoxide, and carbon dioxide. First, it is deoiled, dehydrated, and high-boiling components are removed, and then it is further purified by low-temperature adsorption. The low temperature adsorption process of the present invention is in figure 1 in the process shown. on the whole, figure 1 Including cooling system and adsorption system two parts.

[0025] figure 1 The cooling system shown is a pre-cooling heat exchanger C, a liquid nitrogen evaporator D and its level gauge E; however, multiples of each device of the present invention may be used. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com