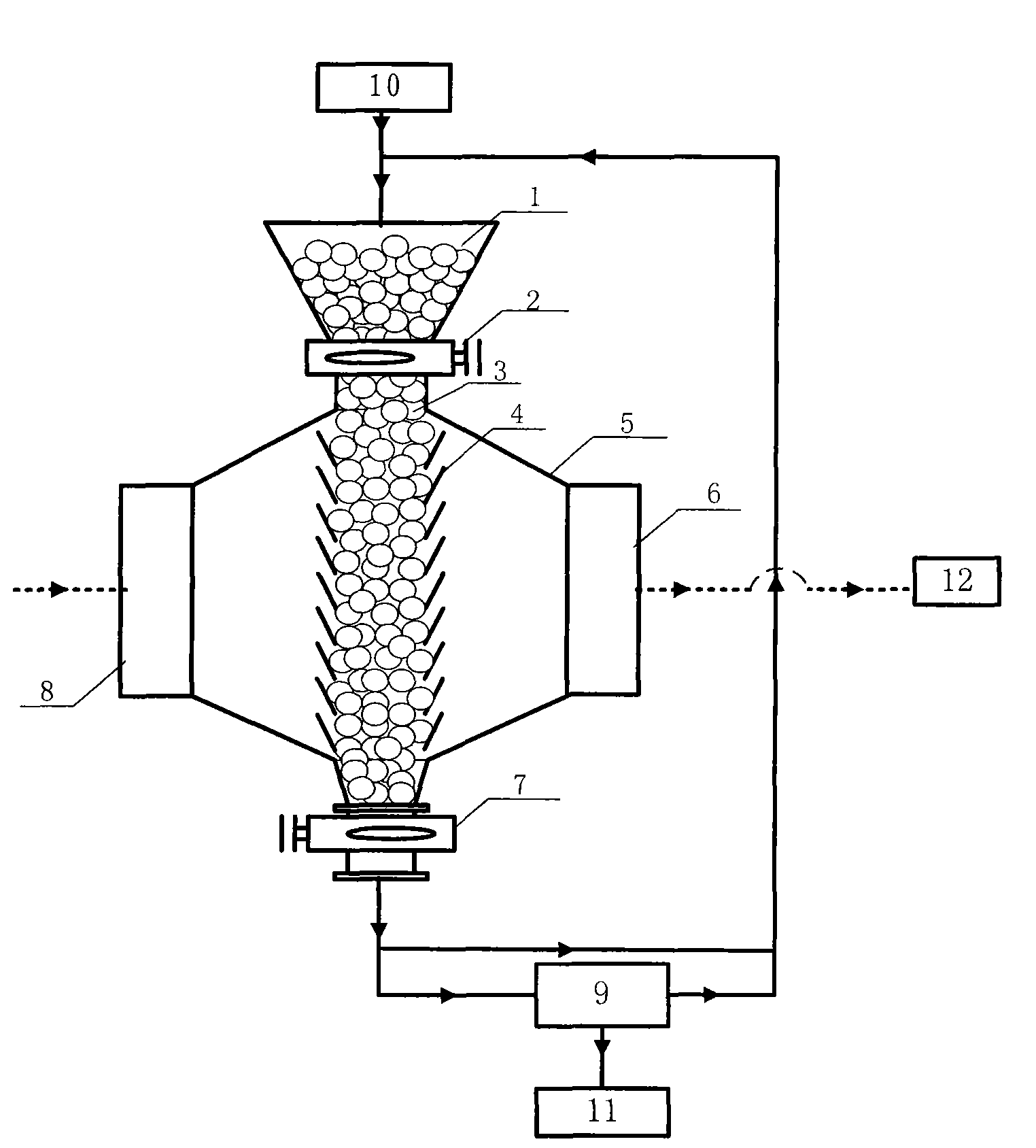

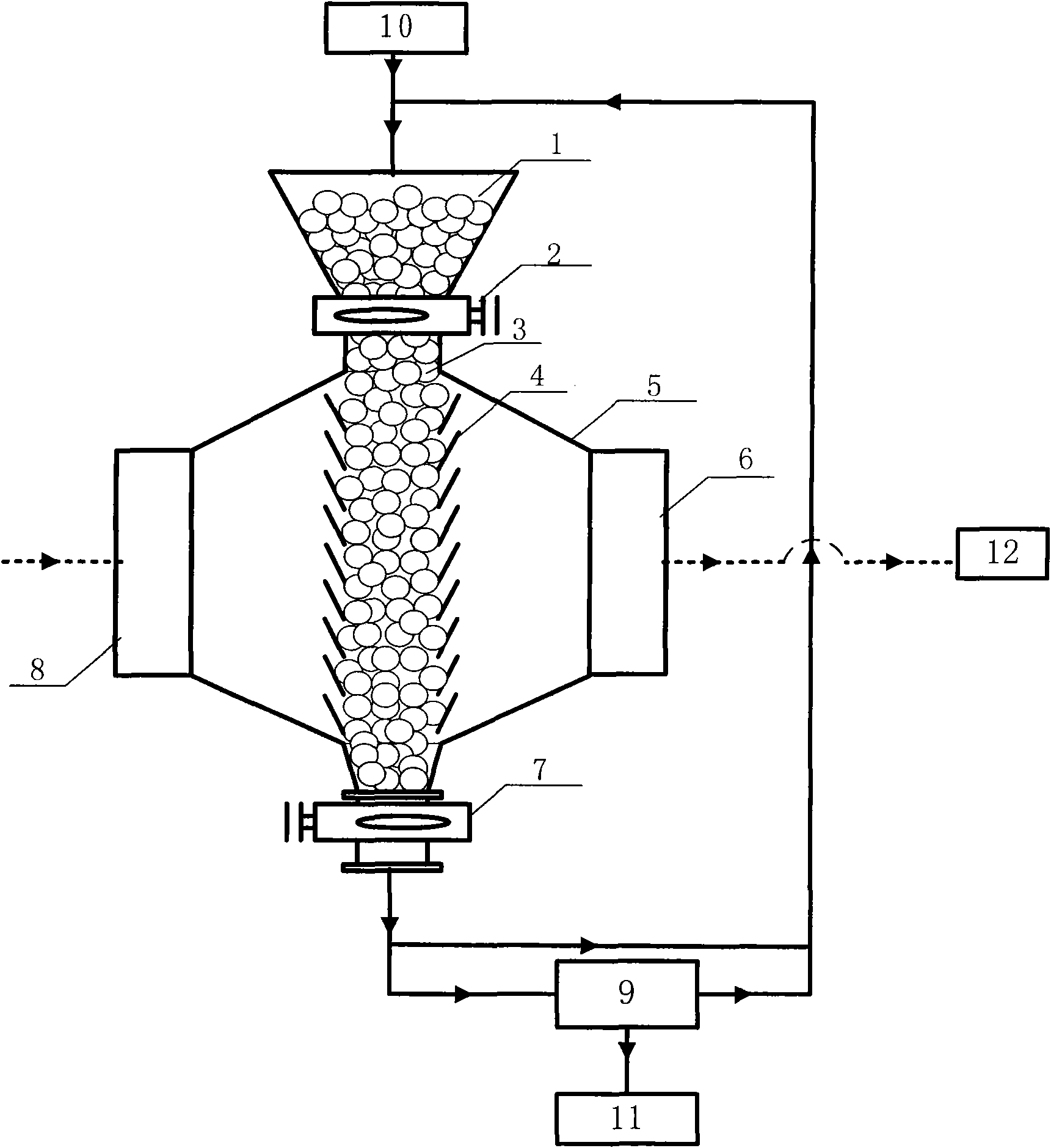

Device and method for removing harmful components from gas in cement kiln by utilizing cross-flow moving bed

A harmful component, cement kiln technology, applied in the field of sulfur, chlorine, and alkali removal in the cement clinker firing process, can solve problems such as crusting and blockage, achieve less drop in flue gas temperature, low construction cost, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1, harmful components such as alkali, chlorine, and sulfur contained in the kiln gas will condense at about 700 ° C, and then

[0037] Causing crust clogging. The exhaust gas temperature of the lowest stage cyclone separator is about 750°C, so the condensation of harmful components usually begins in the penultimate stage preheater. It is designed that the flue gas from the lowest cyclone separator passes through the cross-flow moving bed absorber, and flows cross-flow with the adsorption carrier in the cross-flow moving bed absorber. Alkali, chlorine, sulfur and other harmful components are condensed on the adsorption carrier when cold, and are discharged out of the absorption tower together with the adsorption carrier. In this way, the problem of crust blockage caused by the cyclic enrichment of harmful components such as alkali, chlorine, and sulfur is solved.

Embodiment 2

[0038] Example 2, for the preheating system that has been installed with bypass ventilation equipment, the exhaust gas can be passed through the cross-flow moving bed absorber first, and after the harmful components are removed, it can be directly sent to the raw meal preheater to heat the raw meal , recovering the heat in it, thereby reducing heat loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com