A kind of Portland cement clinker and its preparation method and production equipment

A Portland cement and production equipment technology, applied in cement production, etc., can solve the problems of occupying land resources, occupying large land, water pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A Portland cement clinker, the cement clinker formula includes 80-84% of limestone, 4-8% of dedusting ash, 4-8% of graphite tailings, and 4-6% of silica.

[0030] 2. A Portland cement clinker according to claim 1, characterized in that the CaO in the limestone is greater than 47%, and the SiO in the silica 2 More than 80%, Fe in dust removal ash 2 o 3 More than 40%, Al in graphite tailings 2 o 3 Greater than 17%.

[0031] The preparation method of Portland cement clinker comprises the following steps:

[0032] S1: Put the raw material prepared according to the proportion into the raw material mill for grinding, and control the amount of water spraying at 0.5-2 cubic meters per hour while grinding, and the grinding pressure at 8Mpa;

[0033] S2: drying the raw meal after grinding, wherein the comprehensive moisture content of the incoming raw meal is less than 5%, and the moisture content of the outgoing raw meal is less than 0.5%;

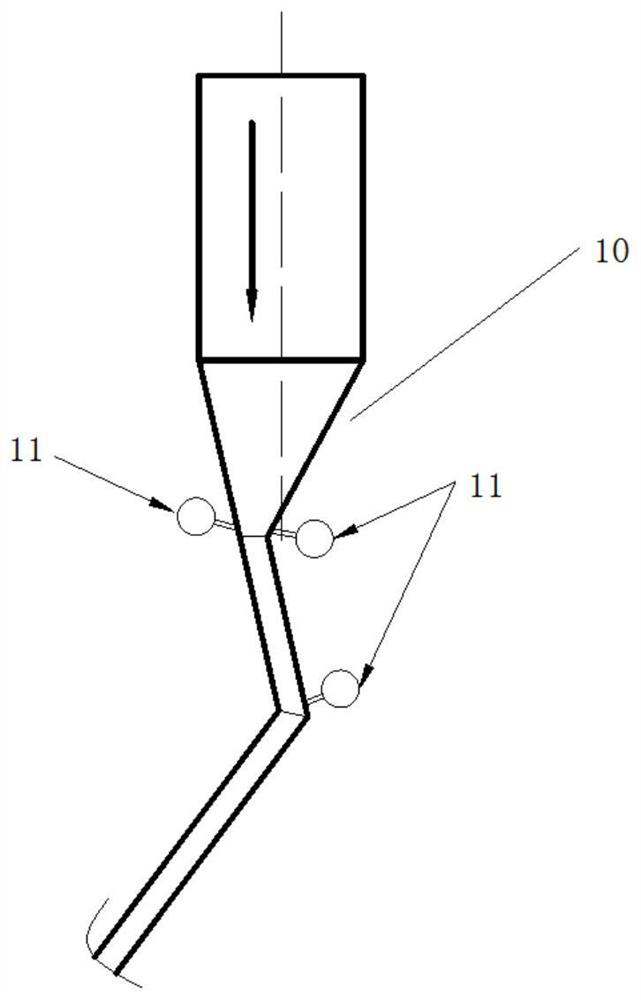

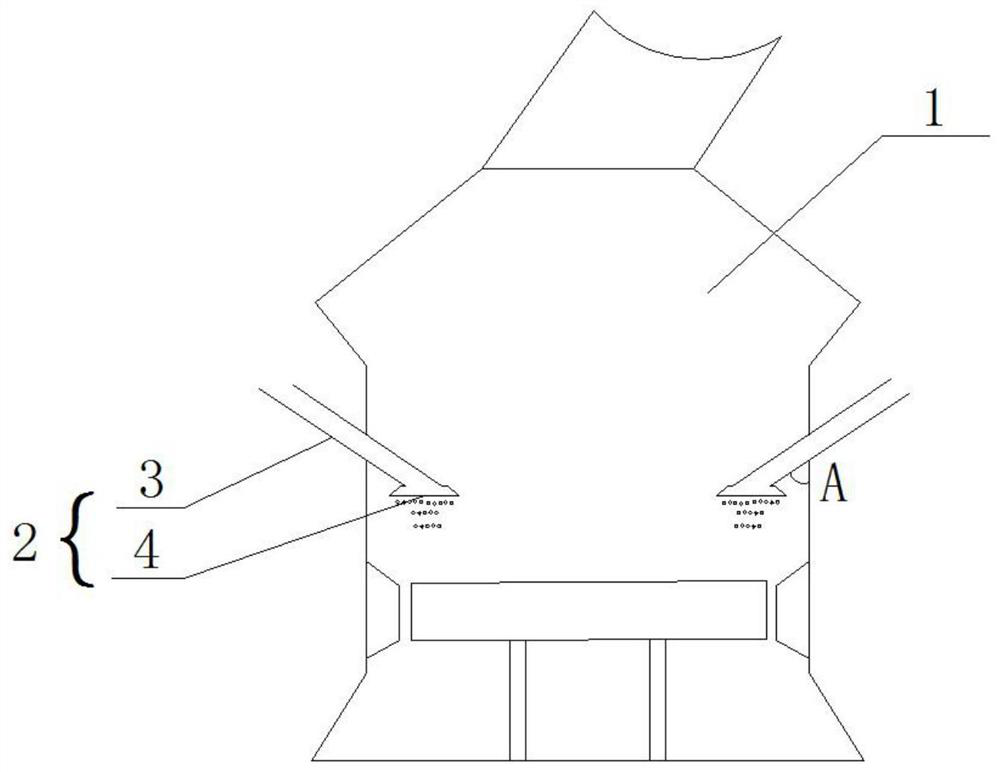

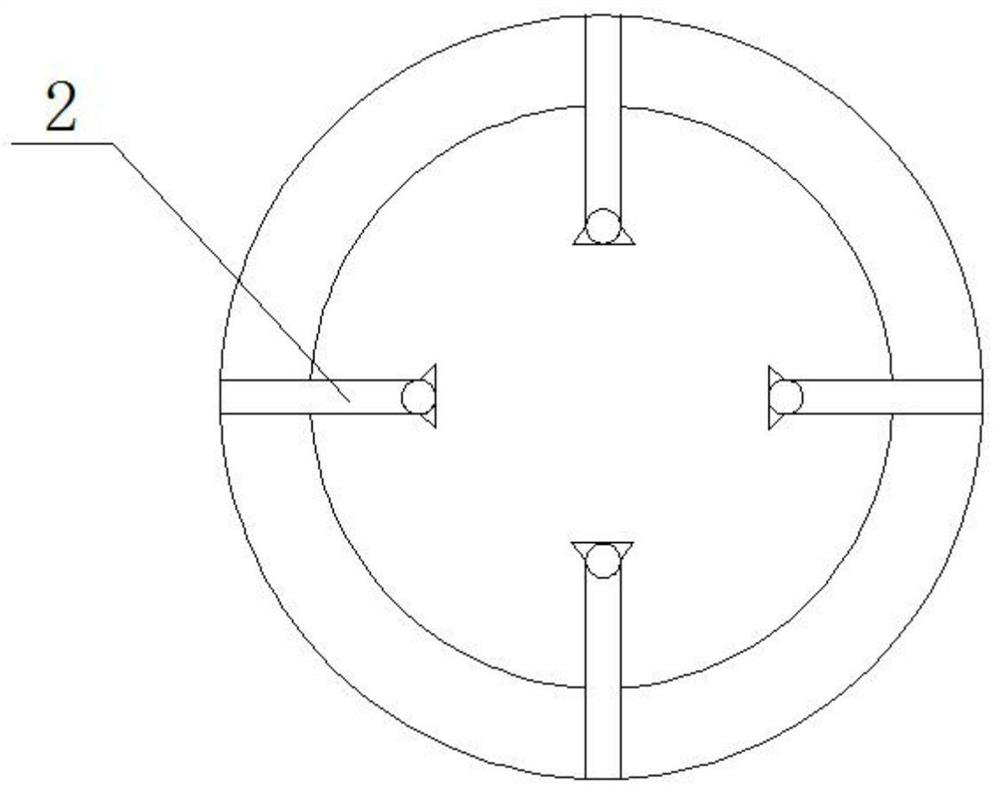

[0034] S3: pass the dried raw m...

Embodiment 2

[0046] A Portland cement clinker, the formula of the cement clinker includes 81.8% of limestone, 6.1% of dedusting ash, 6.4% of graphite tailings and 5.6% of silica. Production mode is the same as embodiment one.

Embodiment 3

[0048] A Portland cement clinker, the formula of the cement clinker includes 80.4% of limestone, 7.2% of dedusting ash, 7.4% of graphite tailings and 5% of silica. Production mode is the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com