Rotary hearth furnace raw material water-washing dechlorination system and water-washing dechlorination technology thereof

A raw material water and rotary hearth furnace technology, which is applied in the water washing dechlorination system and process field, can solve the problems of equipment gas phase corrosion, thermal corrosion, crust blockage, etc., and achieve the effect of solving gas phase corrosion and thermal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

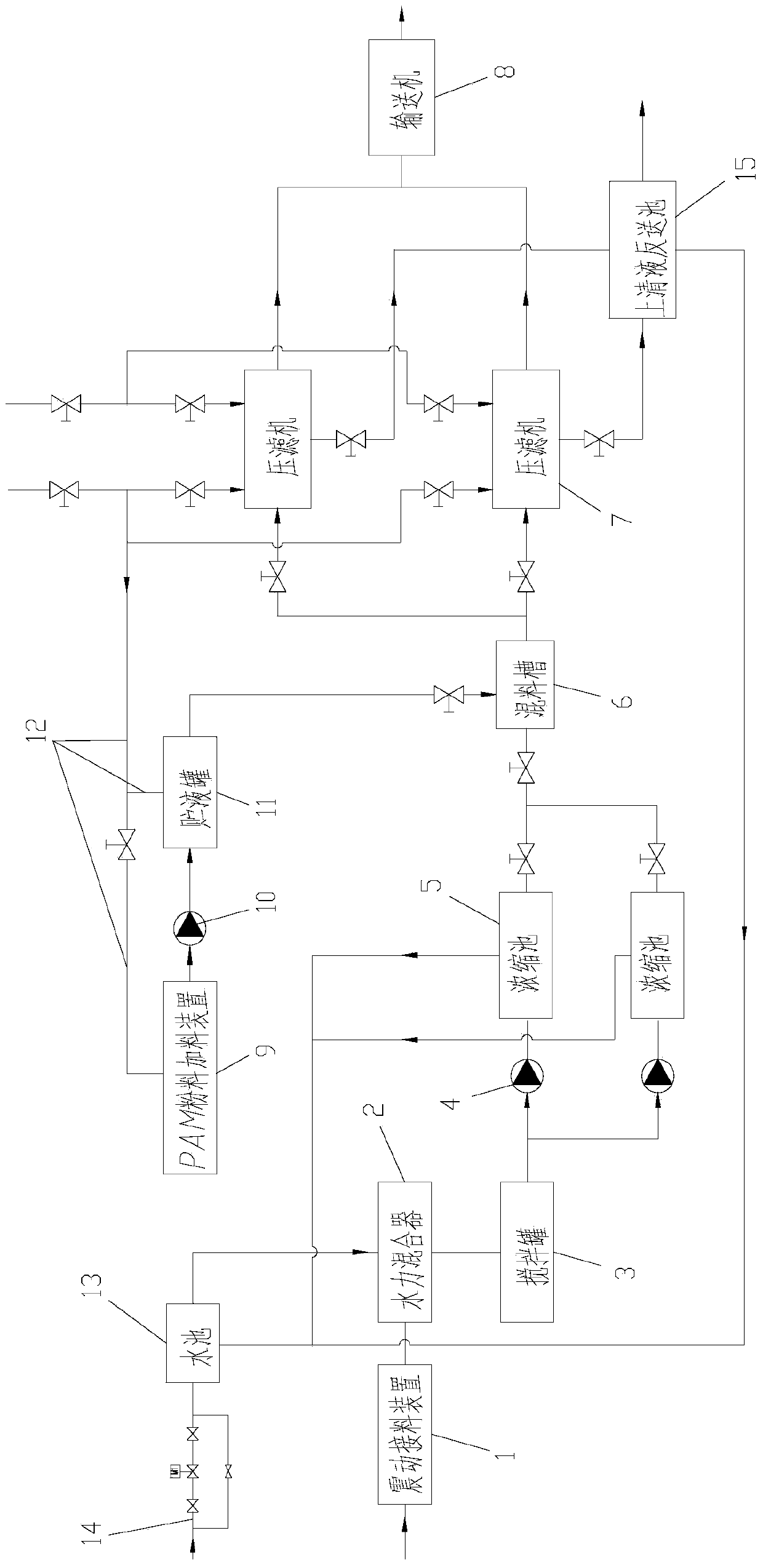

[0024] As shown in the figure, the rotary hearth furnace raw material water elution chlorine removal system in this embodiment includes a vibrating material receiving device 1, a hydraulic mixer 2, a stirring tank 3, a mud pump 4, a thickening tank 5, a mixing tank 6 and a filter press 7. It also includes a dosing system for adding PAM to the mixing tank and a water adding system for adding water to the hydraulic mixer 2, the dosing system, and the filter press 7;

[0025] The vibrating material receiving device 1 is used to loosely add materials to the hydraulic mixer 2. In this embodiment, the vibrating material receiving device 1 adopts a floating sieve filter type, which can vibrate in any direction and has a sieve filter function, which can make the next The material is loose and uniform, so as to prevent the hardened block material from entering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com