Hydrogen and helium gas mixture separation and recovery device

A technology of mixed gas and recovery device, applied in hydrogen separation, separation method, dispersed particle separation, etc., can solve the problem of not seeing and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

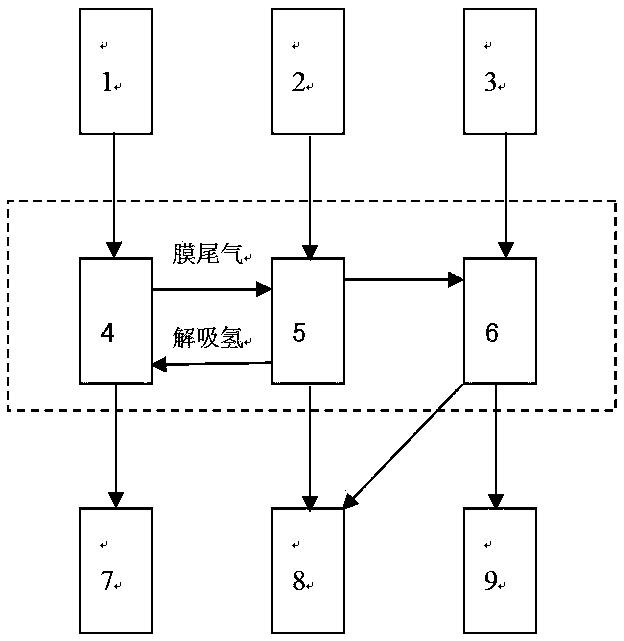

[0018] Example 1 Separation and recovery of high-concentration hydrogen-helium mixed gas

[0019] The high-concentration hydrogen-helium mixed gas directly enters the membrane separator. After membrane separation, the hydrogen-permeable end gas is introduced into the hydrogen storage tank, and the membrane tail gas enters the low-temperature adsorption bed. After entering the helium storage tank, the water produced by oxidation is collected in the water storage tank; there is still a certain amount of helium in the desorbed hydrogen, which is returned to the membrane separator for further separation to obtain high-purity hydrogen and a small amount of hydrogen-helium mixed gas, and the hydrogen-helium mixed gas enters again Low-temperature adsorption bed, so that both high-purity hydrogen and high-purity helium can be obtained.

[0020] The membrane used in this example is a palladium-silver alloy membrane, the raw material gas is hydrogen-helium mixed gas containing 96% hyd...

Embodiment 2

[0023] Example 2 Separation and recovery of high-concentration hydrogen-helium mixed gas

[0024] The difference between this embodiment and embodiment 1 is that the following parameters are different, and all the other are the same as embodiment 1

[0025] The raw material gas is a hydrogen-helium mixture containing 92% hydrogen, and the inlet flow rate is controlled at 1.5L / min; the catalytic oxidation bed is a silver oxide column, and the reaction temperature is 260°C. Hydrogen with a purity of 99.5% is obtained at the hydrogen permeable end, and the hydrogen recovery rate reaches 97.4%; the volume concentration of hydrogen in the helium flowing out of the cryogenic adsorption bed is less than 20ppm, and the hydrogen volume concentration in the helium flowing out of the catalytic oxidation bed is less than 10ppm.

Embodiment 3

[0026] Example 3 Separation and recovery of hydrogen-helium mixture gas in the middle hydrogen concentration range

[0027] The medium-concentration hydrogen-helium mixed gas is connected to the low-temperature adsorption bed, and the helium gas containing trace hydrogen flowing out after low-temperature adsorption enters the catalytic oxidation bed (more needed when tritium is involved). A small amount of water is collected in the water storage tank; desorbed hydrogen contains a certain amount of helium, which enters the membrane separator for further separation to obtain high-purity hydrogen and a small amount of hydrogen-helium mixed gas, and the hydrogen-helium mixed gas enters the low-temperature adsorption bed again, so that high-purity hydrogen can be obtained , and high-purity helium can be obtained. The hydrogen volume concentration of the hydrogen-helium mixed gas is 10%, and the low-temperature adsorption bed is a 5A molecular sieve bed. The adsorption temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com