Metal system for testing outgassing property of low-temperature material

A low-temperature material and metal technology, applied in the field of metal systems, can solve problems such as inconvenient use and maintenance, large measurement errors, and fragile glass materials, and achieve the effects of improving accuracy, reliable test results, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

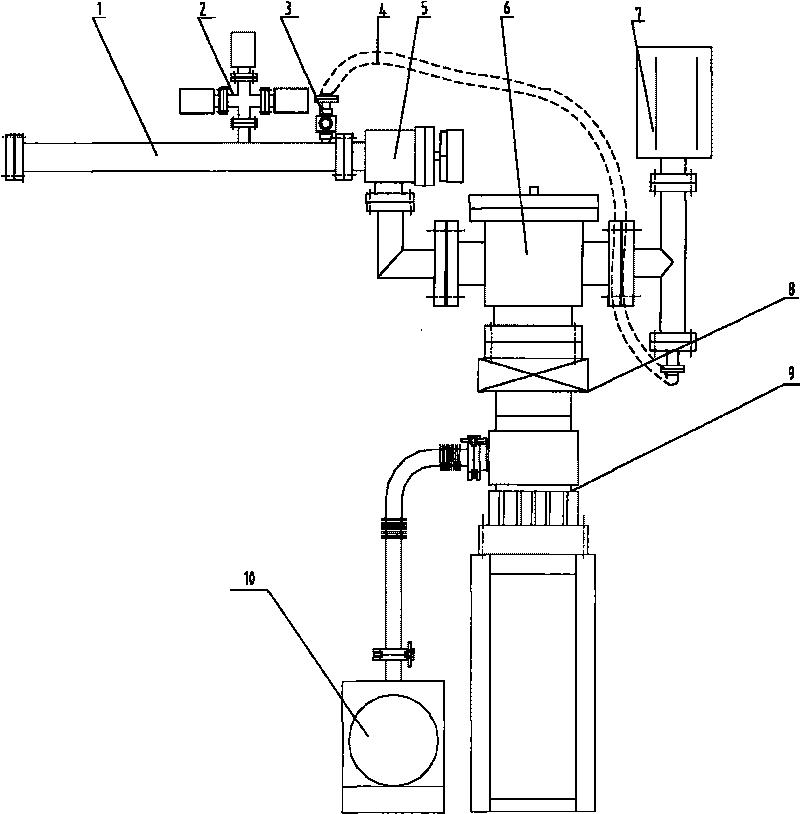

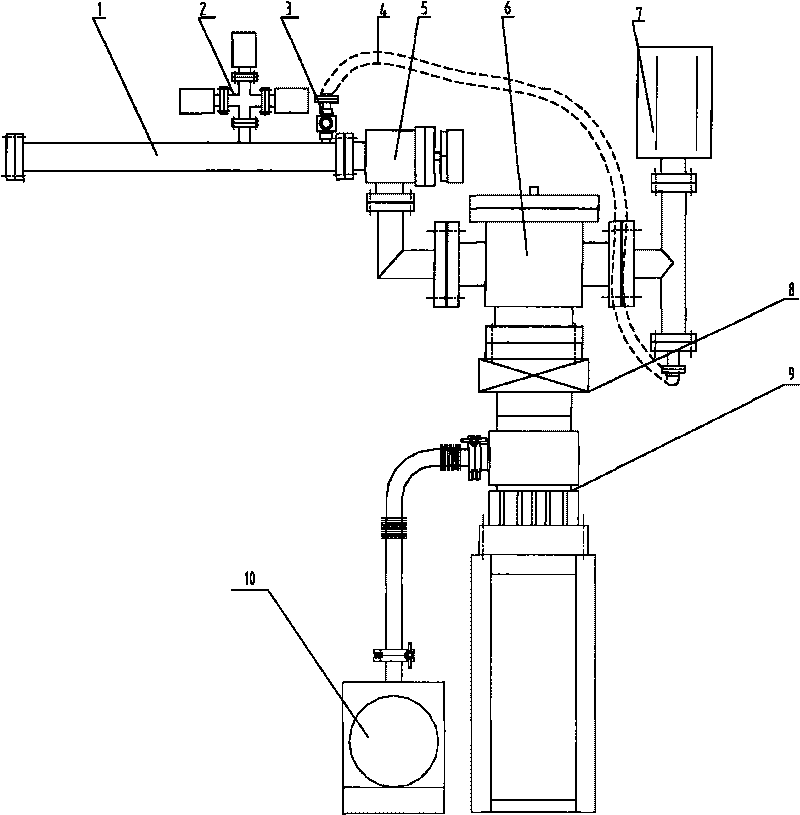

[0014] Such as figure 1 As shown, it is a structural schematic diagram of the system of the present invention, wherein, 1-sample chamber, 2-capacitance gauge, 3-trimming valve, 4-metal hose, 5-high vacuum angle valve, 6-liquid nitrogen cold trap, 7- Mass spectrometer, 8-gate valve, 9-molecular pump, 10-mechanical pump; the evacuation system composed of mechanical pump 10 and molecular pump 9 first vacuumizes the sample in the sample chamber 1, where the inner diameter of the sample chamber is Φ40mm , a cylindrical body with a wall thickness of 1.5mm and a length of 500mm. At the same time, the liquid nitrogen cold trap 6 performs low-temperature adsorption on the oil vapor generated by the system. When the pressure of the sample chamber 1 is pumped to 1×10 -3 Pa, close the high-vacuum angle valve 5 and the gate valve 8, and use the capacitance gauge 2 to test the pressure change in the sample chamber 1 within a specified time, so as to calculate the outgassing rate of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com