Flow resistance and temperature distribution testing device for low-temperature fluid inside heat insulating corrugated pipes

A low-temperature fluid and flow resistance technology, which is applied in the field of low-temperature fluid flow and heat transfer characteristic test equipment, and low-temperature fluid flow resistance and temperature distribution test equipment in adiabatic bellows. Change performance measurement and other issues to achieve the effect of simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

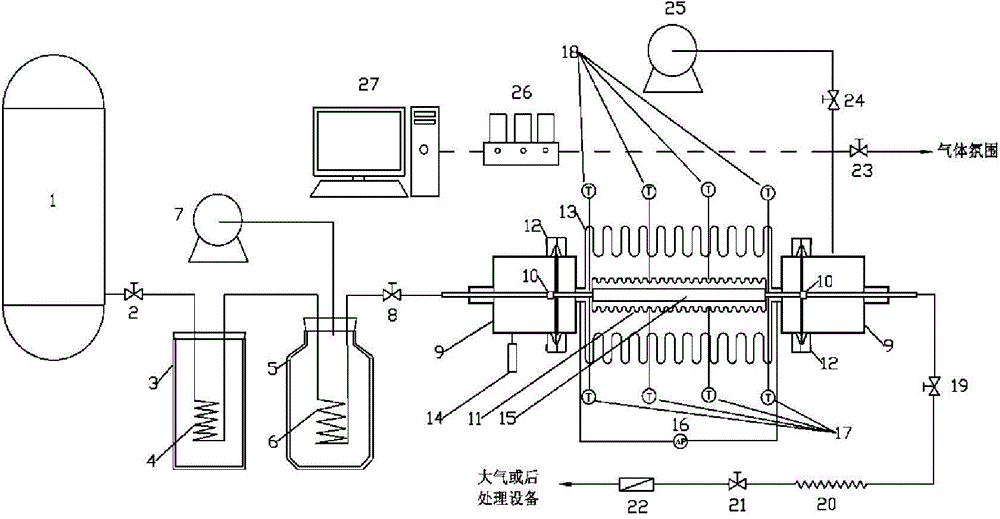

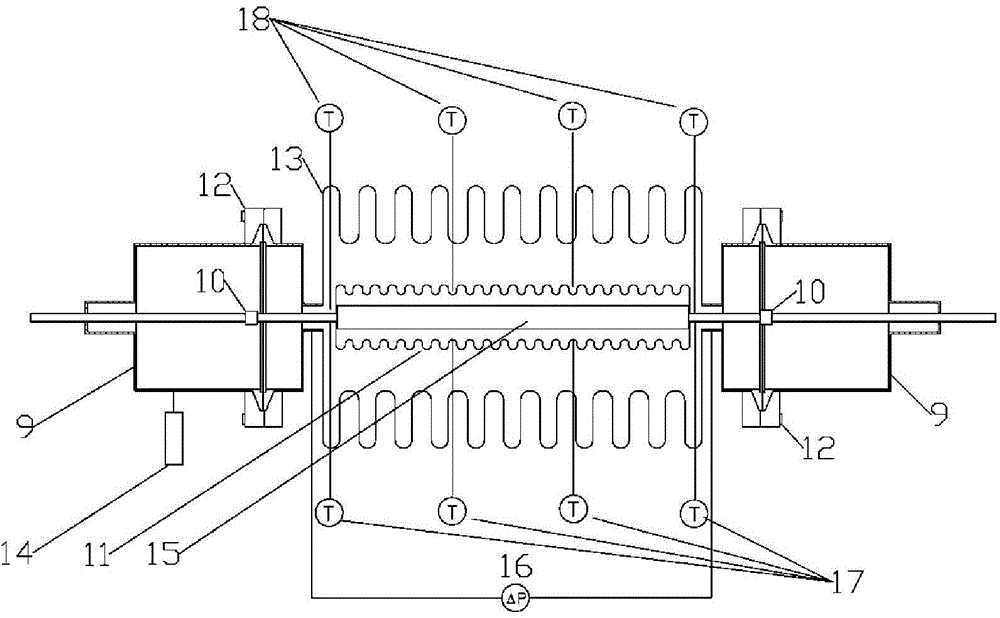

[0026] A device for testing the flow resistance and temperature distribution of low-temperature fluid in a thermally insulated bellows, such as figure 1 , figure 2 As shown, the test device includes a low-temperature self-pressurized storage tank 1, a two-stage subcooler, a bellows experimental section, a vaporizer 20, and a gas flow meter 22 connected by a metal hose. A pressure regulator is provided on the metal hose. Valve 2, flow regulating valve 8, back pressure regulating valve 19 and switch valve 21, pressure regulating valve 2 is located between low temperature self-pressurizing storage tank 1 and two-stage subcooler, flow regulating valve 8 is located in two-stage subcooling Between the evaporator and the experimental section of the bellows, the back pressure regulating valve 19 is provided between the experimental section of the evaporator and the vaporizer 20, and the switch valve 21 is provided between the vaporizer 20 and the gas flow meter 22.

[0027] The two-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com