Method and system for measuring reverse friction of vehicle steering system

A technology of steering system and reverse friction, which is applied in the direction of vehicle steering/bump performance, can solve the problems of high cost and complicated operation of measurement methods, and achieve the effect of low cost, strong operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An inverse friction measurement system for a vehicle steering system of the present invention, its basic composition and connection method are: at least one power device for providing steering torque, a turntable for driving the wheels to rotate synchronously, and for measuring the rotation angle of the wheels and measuring The power device is a measurement unit for outputting driving torque, and a processing operation unit for processing the data collected by the measurement unit, and the power device drives and connects the turntable.

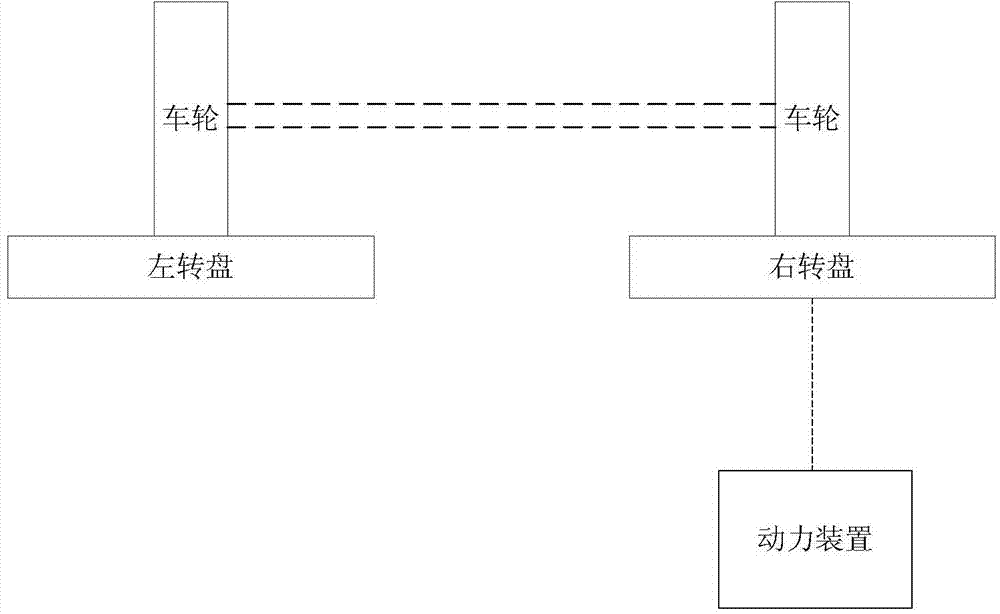

[0030] Such as figure 1 As shown, it mainly includes two turntables corresponding to the wheels on the same axle of the vehicle to be tested, and a power unit. The power unit is connected to the left turntable or right turntable.

[0031] First, the power unit is driven and connected to one of the turntables, and the other turntable can rotate freely, placing the front wheels of the vehicle on the left and right turntables respectively...

Embodiment 2

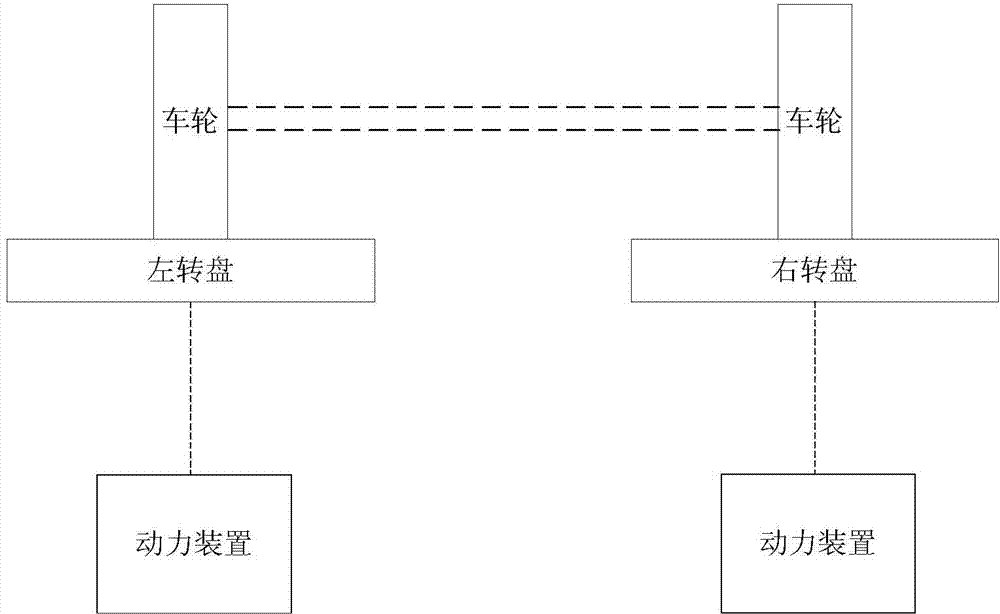

[0040] Such as figure 2 As mentioned above, the only difference from Embodiment 1 is that it includes two power units and left and right turntables corresponding to the left and right wheels on the same axle of the vehicle to be tested, and each power unit is respectively driven and connected to the left and right turntables.

[0041] The specific implementation process is similar to that of Embodiment 1, and the similar parts will not be repeated here.

[0042] Specifically, compared with the calculation formula of the reverse friction torque in embodiment 1, the calculation formula of the reverse friction torque in embodiment 2 also needs to be changed correspondingly, the reverse friction torque: M=i*η*(M0 左 +M0 右 )-f*G*r.

Embodiment 3

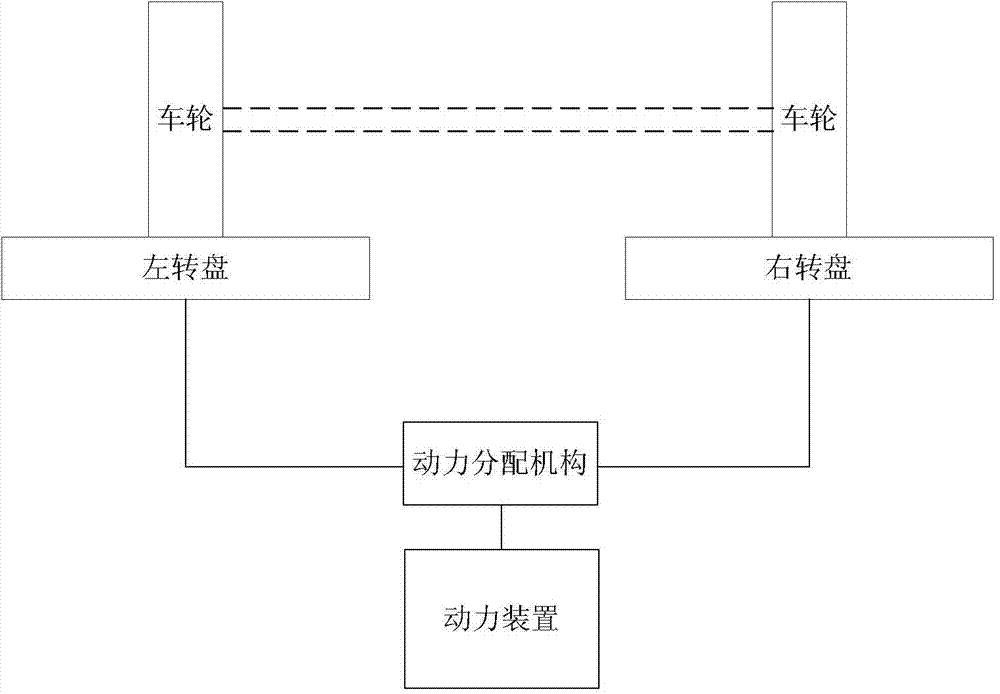

[0044] Such as image 3 As mentioned above, the only difference from Embodiment 1 is that it includes a power unit and left and right turntables corresponding to the left and right wheels on the same axle of the vehicle to be tested, and the power unit is connected to the two turntables through a power distribution mechanism.

[0045] The specific implementation process is similar to the first embodiment, and the similar parts will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com