Leakage check device for metal hoses in batch

A metal hose, leak testing technology, applied in the directions of detecting the presence of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, and applying stable tension/pressure to test material strength, etc., can solve difficult quality problems. Traceability, low production efficiency, high labor intensity and other problems, to achieve the effect of reducing labor intensity, improving production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

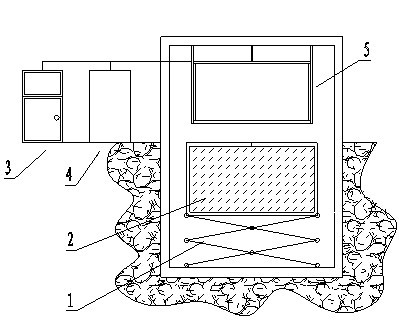

[0019] see figure 1 , the present invention is made up of control part, gas circuit part, lifting water tank 2, and hose support locking mechanism 5, and described control part is controlled by computer device testing process, and test result is recorded and displayed; Said gas circuit part It consists of a compressed air pump 4 and corresponding air pipelines, which provide air sources for the cylinder and the test air circuit; the lifting tank 2 is located at the bottom 5 of the hose support locking mechanism, and the lower part of the lifting tank is provided with a lifting frame 1.

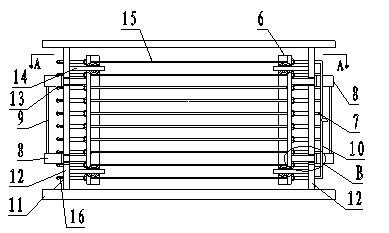

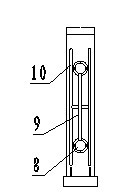

[0020] see Figure 2-5 , the hose support locking mechanism includes a hose frame 11, a pressure plate 6, and a cylinder 8. The hose frame is used to support the tested hose 15, and columns 12 are arranged symmetrically on both sides, and the cylinder 8 is fixed at the column. Two cylinders are fixed up and down by the column; the pressure plate 6 is two pieces, which are respectively arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com