Cutting equipment capable of conveniently cutting off flexible pipe

A technology for cutting equipment and hoses, which is applied in the direction of shearing equipment, metal processing equipment, measuring/indicating equipment, etc. It can solve the problems of burrs left, difficult to guarantee the length, easy to scratch fingers, etc., to achieve uniform length and convenient cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

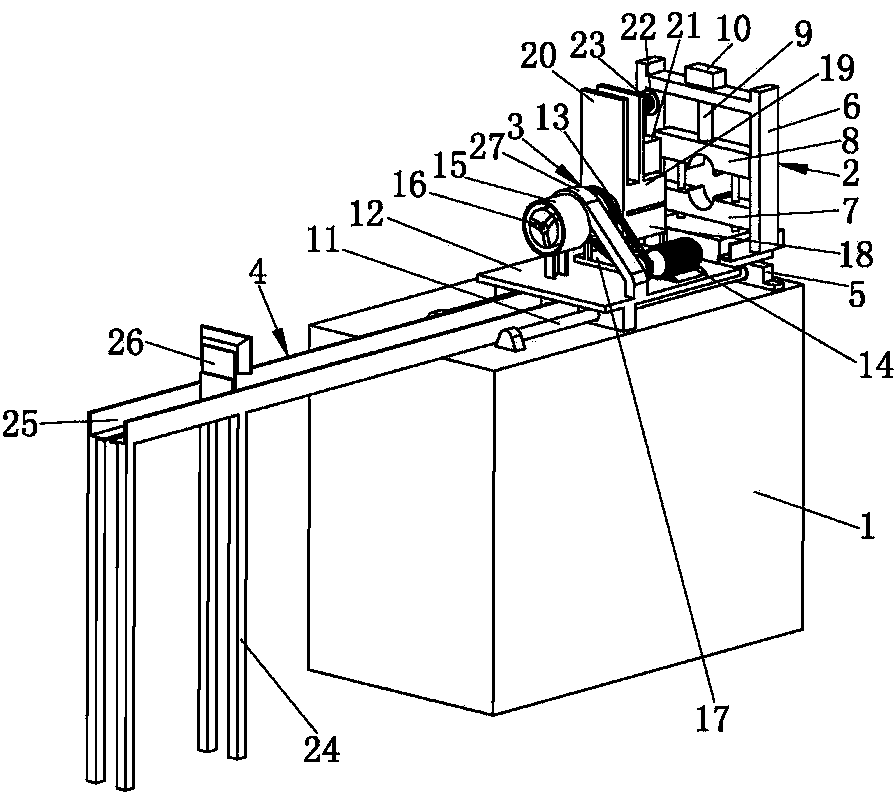

[0026] The present invention is described further below with embodiment, is not to limit the scope of implementation of the present invention hereto.

[0027] Such as figure 1 As shown in the figure, a cutting device for cutting off flexible pipes includes a frame 1, a clamping device 2 is provided at the upper right part of the frame 1, and a cutting device 3 correspondingly connected with the clamping device 2 is provided at the middle part of the upper end of the frame 1. One end of the cutting device 3 is correspondingly provided with a measuring device 4; when the present invention is used, the length of the metal hose to be cut is preset, and the metal hose is clamped by the clamping device 2 and the clamping device, so that the metal hose One end is fixed on the clamping device 2, while the other end is against the measuring device 4, and then the motor 14 drives the cutting roller 15 to rotate, and the metal hose is rotated and cut off by the cutting blade 16 in the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com