Liquid steel temperature fast response infrared continuous measuring device

A technology with fast response and molten steel temperature, which is applied in measuring devices, optical radiation measurement, radiation pyrometry, etc., and can solve problems such as poor response speed of infrared temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

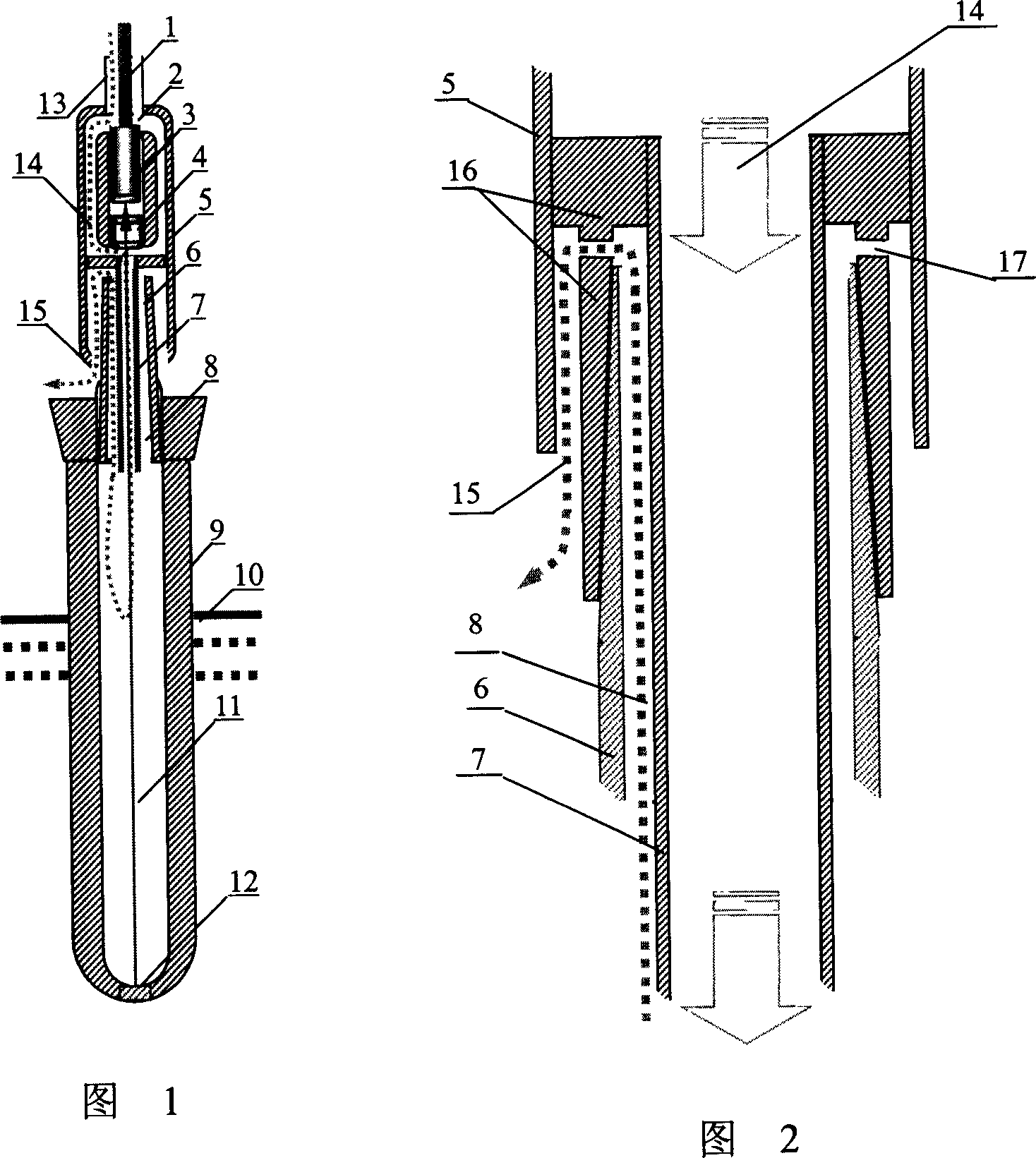

[0020] As can be seen from Fig. 1, the bottom of the present invention is a tubular temperature-measuring tube 9, the temperature-measuring tube 9 is a single-layer structure, its lower end is blind, the upper end is open, and a cylindrical taper shaft connector 6 is packaged at the upper open end; The temperature tube 9 meets the requirements of high temperature resistance, corrosion resistance, erosion resistance, thermal shock resistance, high thermal conductivity, and low density, and can be referred to as: a single-layer high-temperature-conducting temperature-measuring tube. The tube wall of the temperature measuring tube 9 is allowed to generate harmful gas substances and volatilize in its cavity, and the harmful gas phase in the molten steel is allowed to enter the cavity of the temperature measuring tube 9 through penetration and diffusion. The inner and outer surfaces of the blind end of the temperature measuring tube are designed with concentric spherical surfaces to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com