Exhaust pipe for motor vehicle

A technology for exhaust pipes and motor vehicles, which is applied in the direction of exhaust devices, machines/engines, mechanical equipment, etc. It can solve the problems that the exhaust pipe is not suitable for changing the exhaust direction flexibly, and achieves simple manufacturing process, convenient use, and device The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

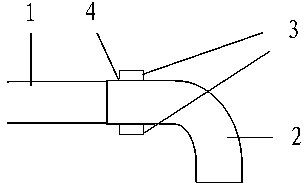

[0009] Such as figure 1 As shown, a motor vehicle exhaust pipe includes an exhaust pipe 1, a metal hose 2 and a screw 3, and the exhaust pipe 1 and the metal hose 2 are fixedly connected by the screw 3. The end of the exhaust pipe 1 is provided with two corresponding perforations 4 for passing through the screws 3 so that the exhaust pipe 1 and the metal hose 2 are fixedly connected. Exhaust pipe 1 is a cast iron pipe. The front end of the metal hose 2 is provided with two corresponding perforations 4 , which coincide with the two corresponding perforations 4 at the end of the exhaust pipe 1 . The metal hose 2 is an aluminum foil hose, which is convenient to twist and change the exhaust gas discharge direction. The metal hose 2 is sleeved on the end of the exhaust pipe 1 . The screw 3 passes through the perforation 4 and the exhaust pipe 1 and the metal hose 2 are fixedly connected. When snow and ice appear on the road surface, twist the metal hose 2 so that its end faces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com