Combined type thin-gauge skin moulding surface trimming cut flexibility multi-supporting equipment

A multi-point support and skin-type technology, which is applied in the direction of shearing device, auxiliary device, workpiece clamping device, etc., can solve the problems of too many physical molds, poor reusability of tooling, long tooling manufacturing time, etc., and achieve cost reduction , reduce special fixtures and tooling, and reduce the effect of coordination links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

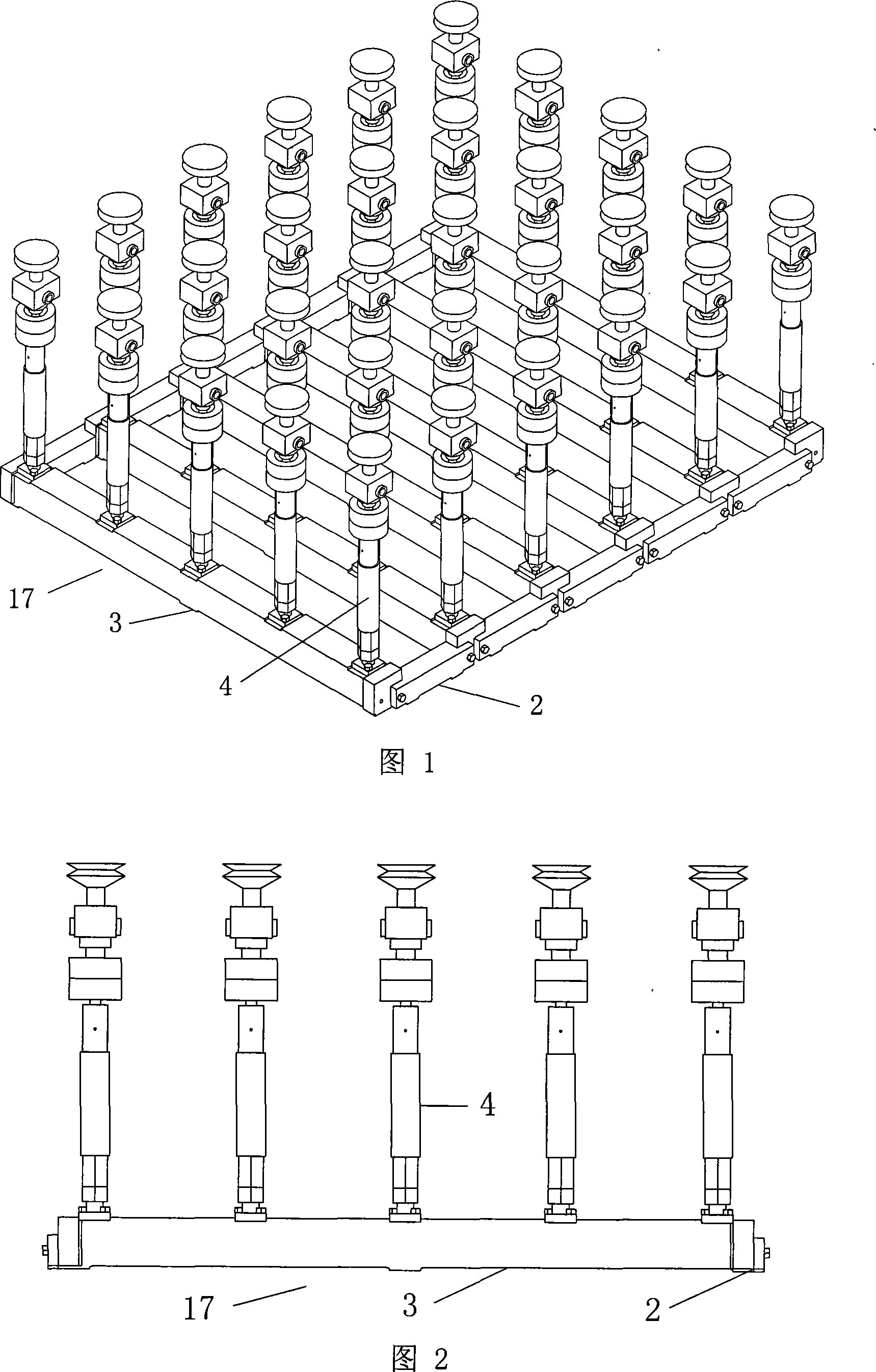

[0039] The present invention is a kind of flexible multi-point support device for trimming of combined skin profile, which adopts the modular design concept, as shown in Fig. 1, is composed of several positioning plates 2, several base pillows 3 and nail height adjustment units The shape-adjusting assembly 17 of 4 forms constitutes.

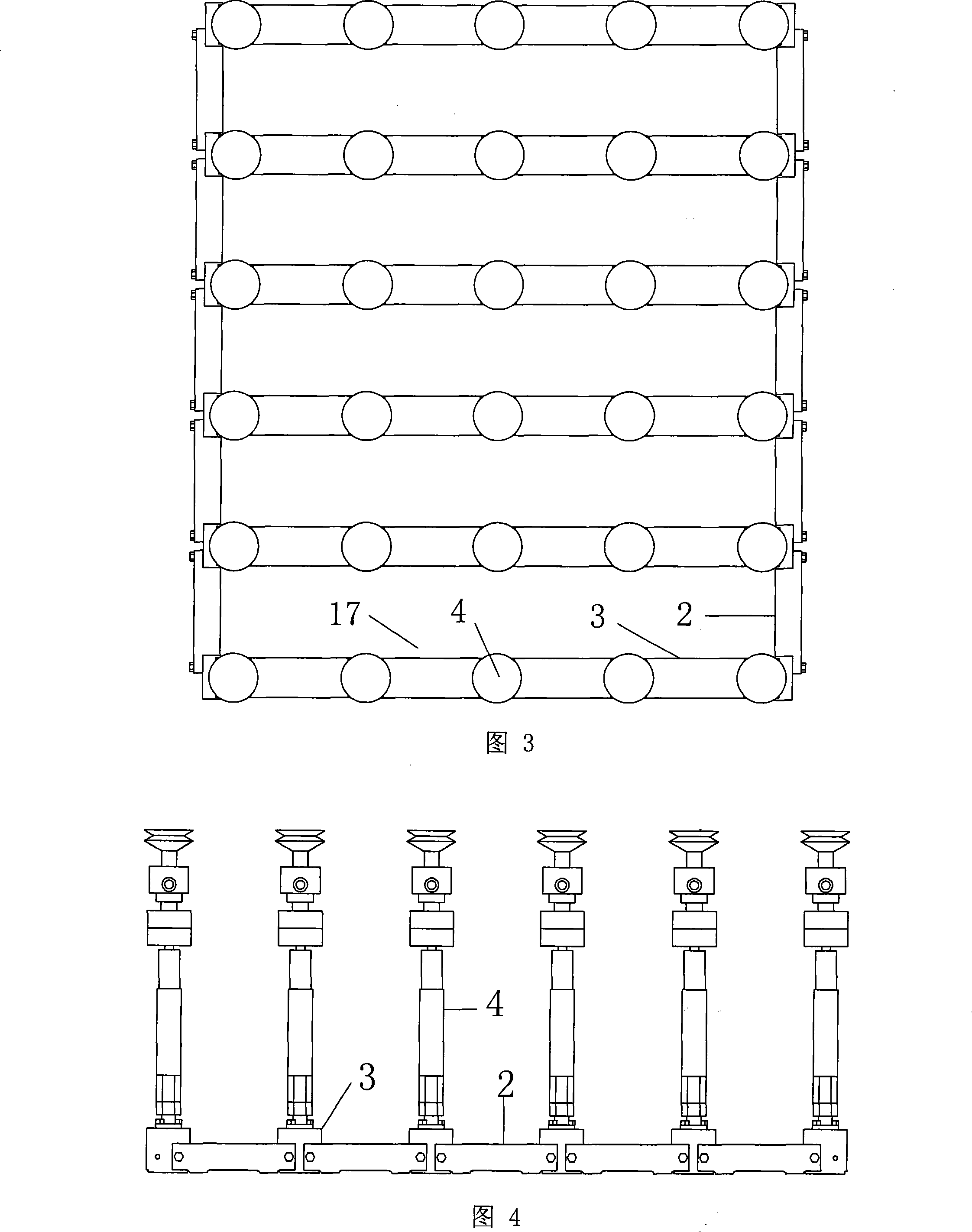

[0040] Among Fig. 2, Fig. 3, Fig. 4: the one placed horizontally is the shape-adjusting assembly 17, and the one placed vertically is the positioning plate 2.

[0041] The positioning plate 2 is a flat "T" shape, on which a threaded hole and a mating surface 20 are provided.

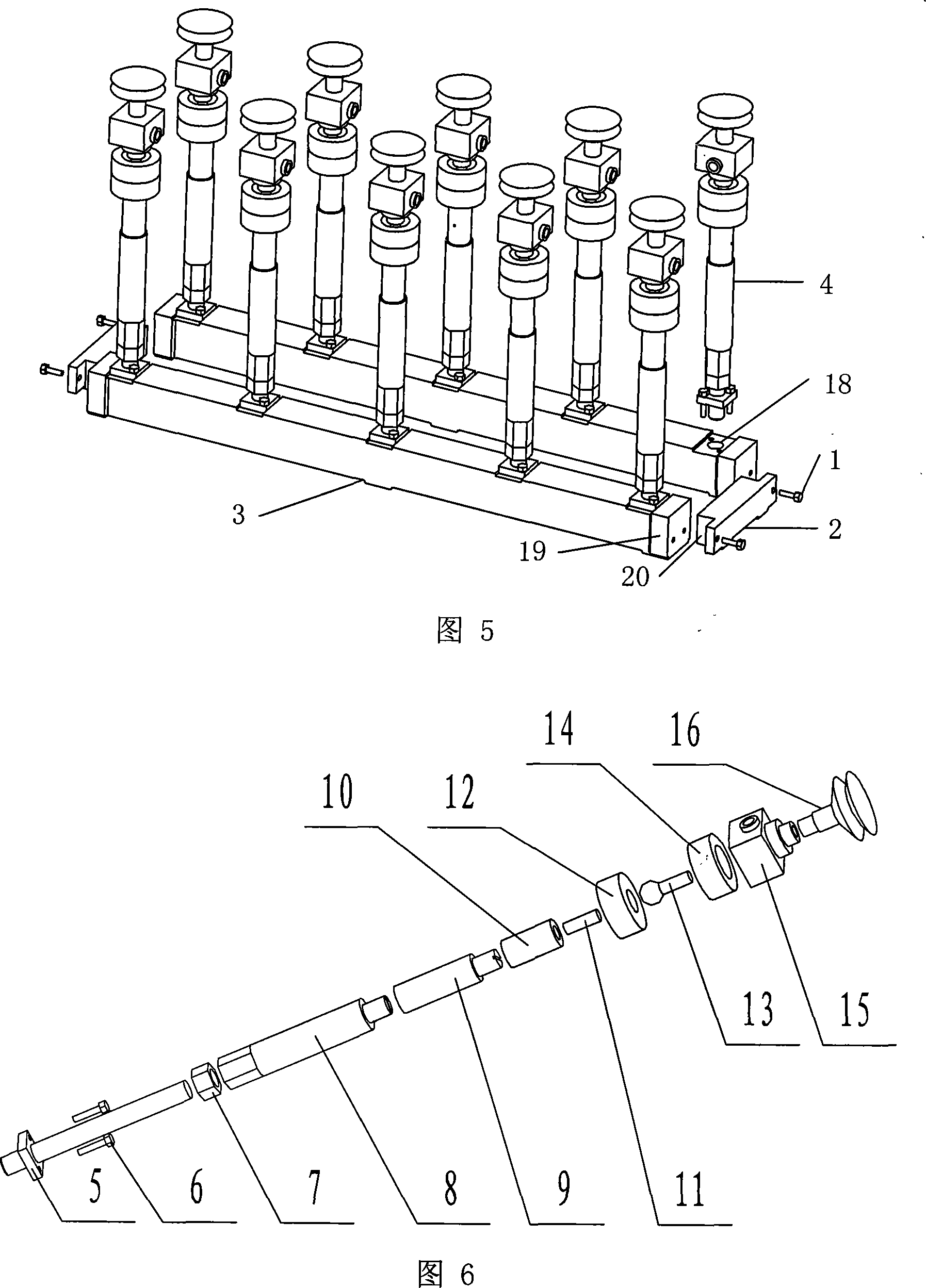

[0042] As shown in FIG. 5 , the shape adjusting assembly 17 is composed of a base pillow 3 and a nail height adjusting unit 4 .

[0043] The base pillow 3 is a cuboid, on which there are positioning holes 18, threaded holes, mating surfaces and the like. Five positioning holes are evenly distributed in a line on the base pillow, and the nail height adjustment units 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com