Swing stamping mechanism

A stamping mechanism and stamping machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of many corner waste, low production efficiency, waste of raw materials, etc., to reduce the cutting process, improve production efficiency, reduce The effect of corner scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

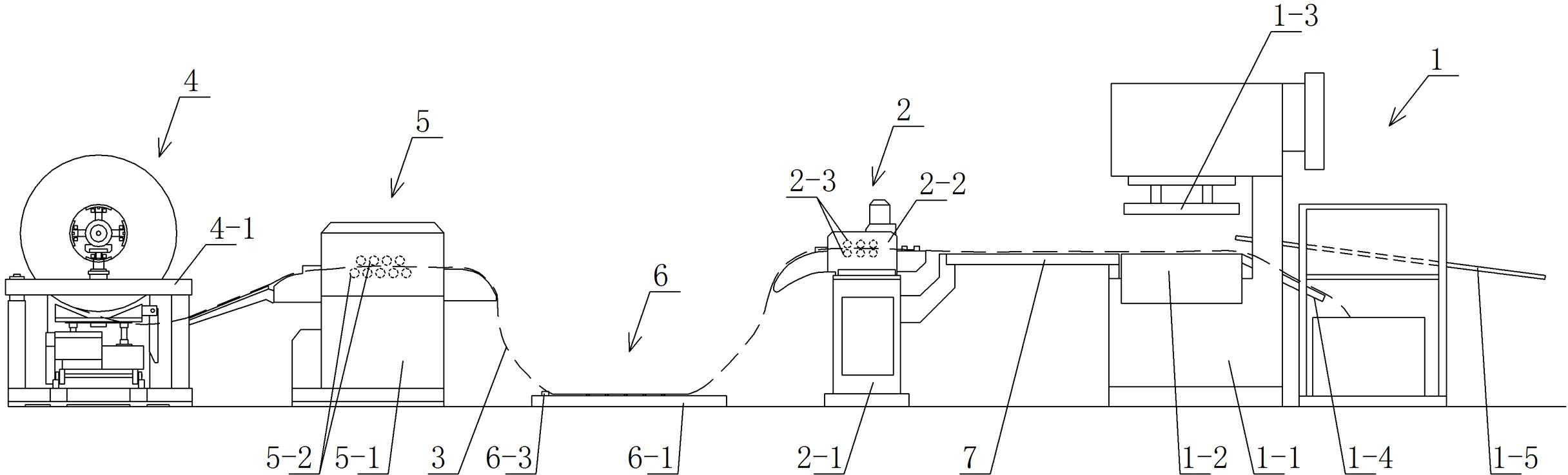

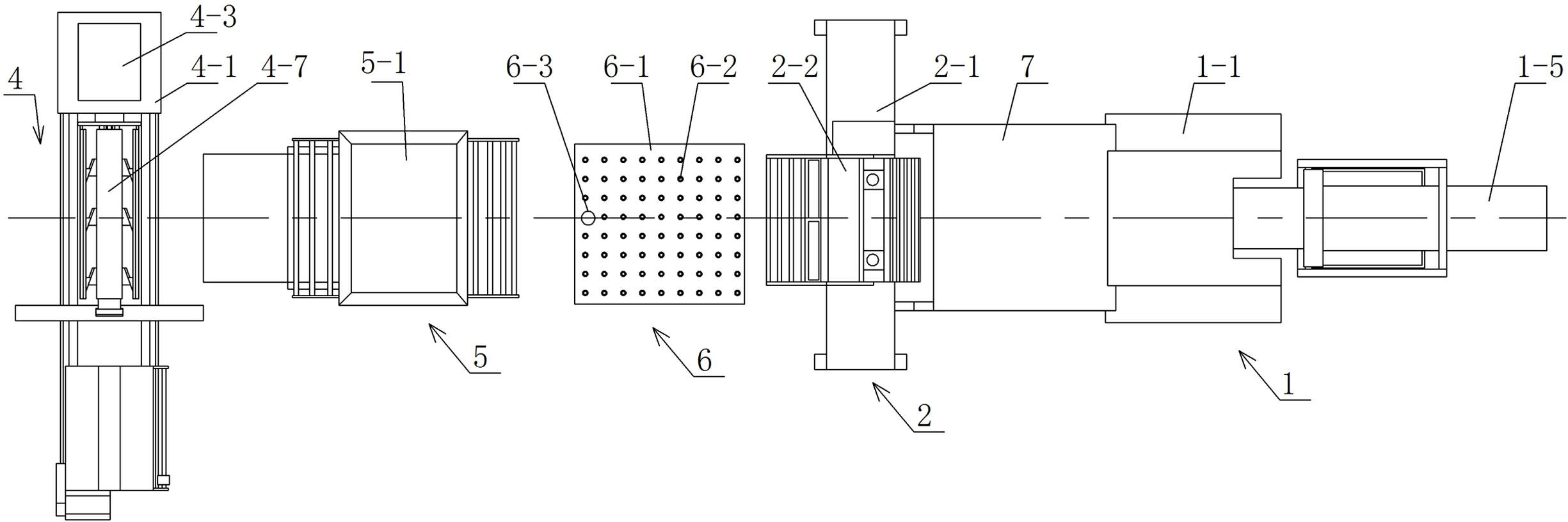

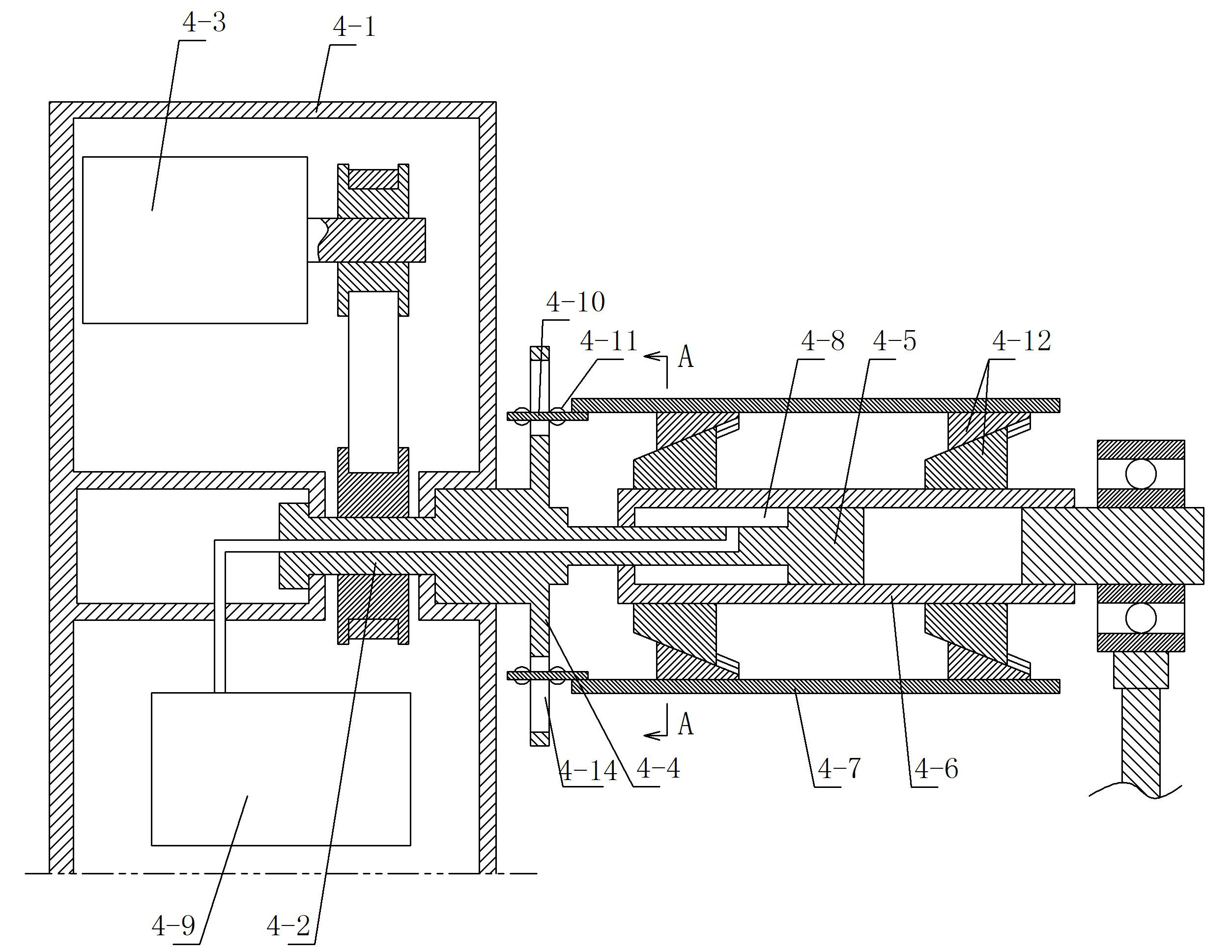

[0030] Such as Figure 1-Figure 5 Shown is a swing stamping mechanism provided by the present invention, which includes a stamping machine 1, the stamping machine includes a punch frame 1-1, a lifting stamping die installed on the punching frame 1-1, and is used to drive the lifting stamping die to carry out The lifting control device for punching work is characterized in that it also includes a numerical control device and a yaw feeder 2 arranged on the rear side of the punching machine 1. The yaw feeder 2 includes a fixed bracket 2-1, which is installed on the fixed bracket The movable frame 2-2 on the frame 2-1 and capable of translating laterally relative to the fixed bracket 2-1 along the direction perpendicular to the advancing direction of the material (such as a steel strip), is connected to the fixed bracket 2-1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com