Metal shell forming method and device

A technology of metal shells and metal sheets, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as cost, damage or strain, and failure to form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

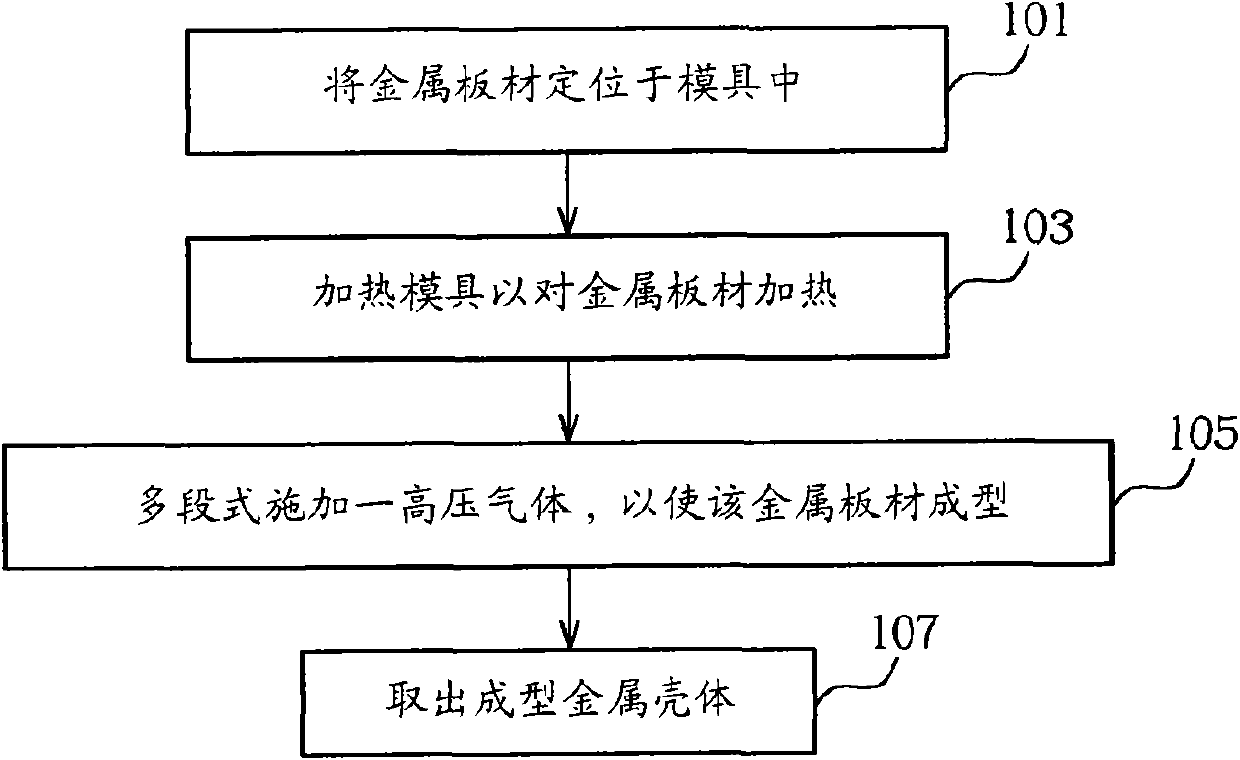

[0031] figure 1 A flowchart showing a method for high pressure forming of a metal shell according to the present invention. Firstly, step 101 is performed to position a metal plate in a mold. The mold includes an upper mold, a lower mold, and a mold kernel. The sheet metal is positioned on the mold core. Next, proceed to step 103 , using a heating device to heat the mold to heat the metal plate. Then, proceed to step 105 , apply a high-pressure gas to the metal plate in a multi-stage manner, forcing the metal plate to be pressed against the surface of the mold core to form a metal shell. Step 107 is further performed to take out the formed metal shell.

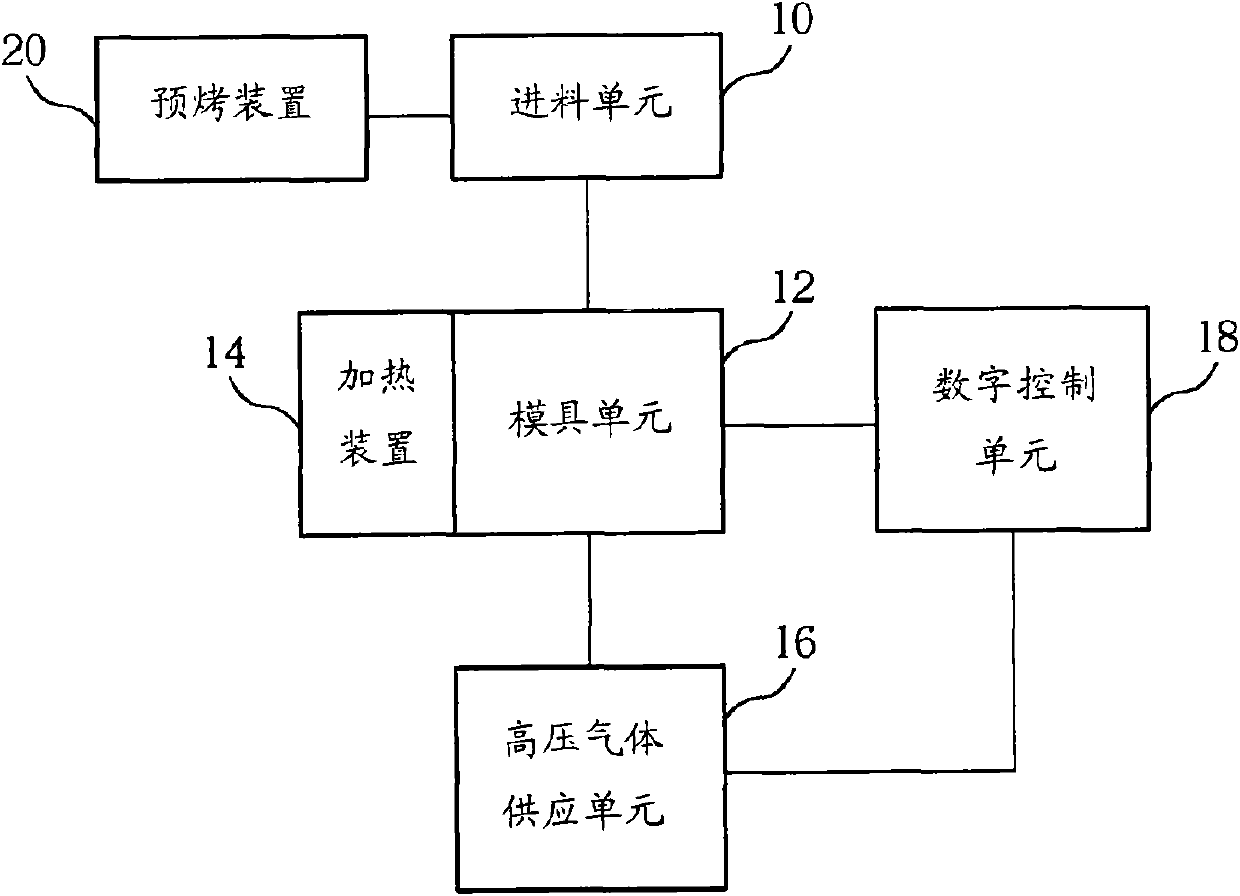

[0032] Metal casing high pressure forming device according to the present invention such as figure 2 As shown in a schematic diagram of an embodiment of the present invention, a feeding unit 10 is used to move a sheet metal to a mold. The mold unit 12 is used for carrying the metal plate. The metal sheet may include, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com