Lever type mechanical downward pushing device of mechanical press

A technology of mechanical press and ejector device, applied in forging/pressing/hammer device, forging/pressing/hammering machinery, push-out equipment, etc., can solve problems such as increasing production cost, reducing production efficiency, and small ejecting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

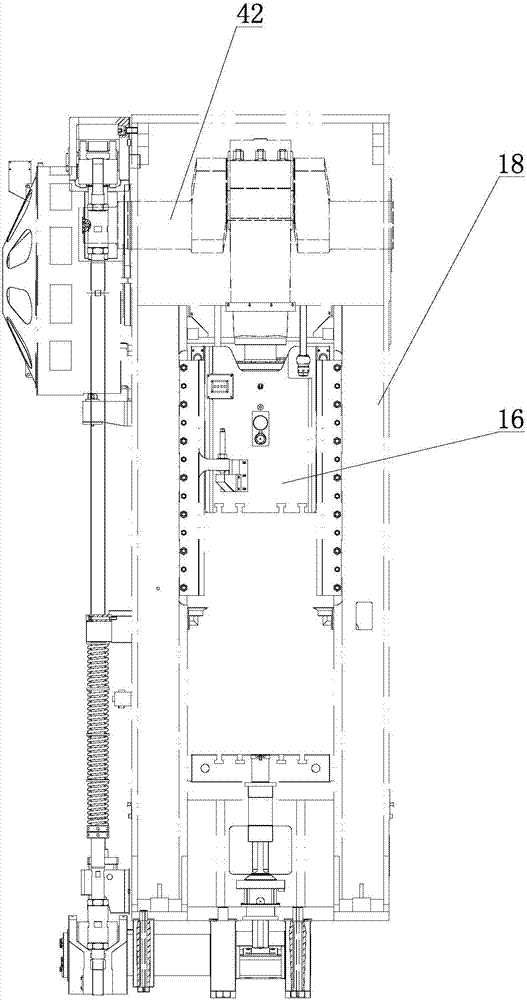

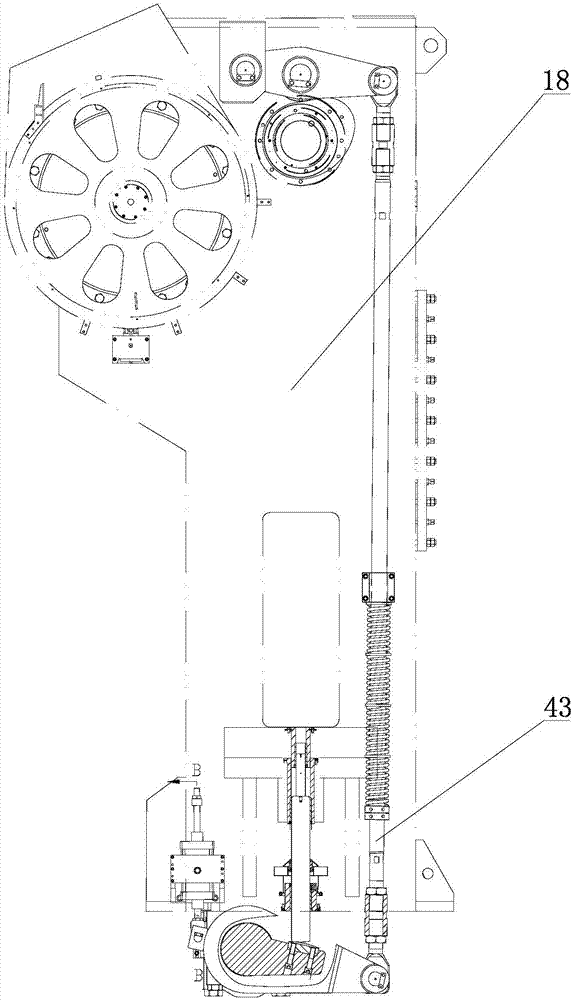

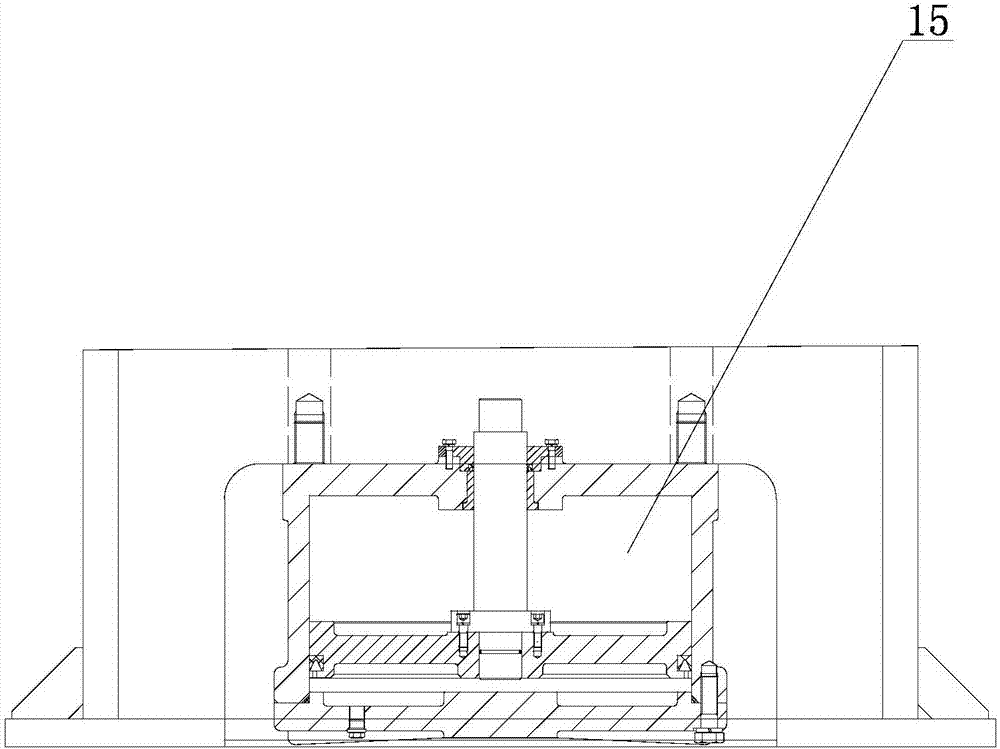

[0039] Such as Figure 4-9As shown, a mechanical press lever type mechanical lower material jacking device includes a slide block 16 installed on the fuselage 18, the two sides of the slide block 16 are respectively provided with brackets 4 connected with the vertical upper pull rod 3, and the upper pull rod 3 passes through The adjustment nut 6 is connected with the pull-down rod 7, the lower end of the pull-down rod 7 is fixedly connected with the pull rod joint 12, the pull rod joint 12 is connected with the outer end of the horizontally arranged lever 14 by turning and sliding, the middle part of the lever 14 is connected with the fulcrum seat 10 arranged on the fuselage 18 Rotationally connected, the other end of the lever 14 is rollingly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com