Patents

Literature

101 results about "Bend Material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

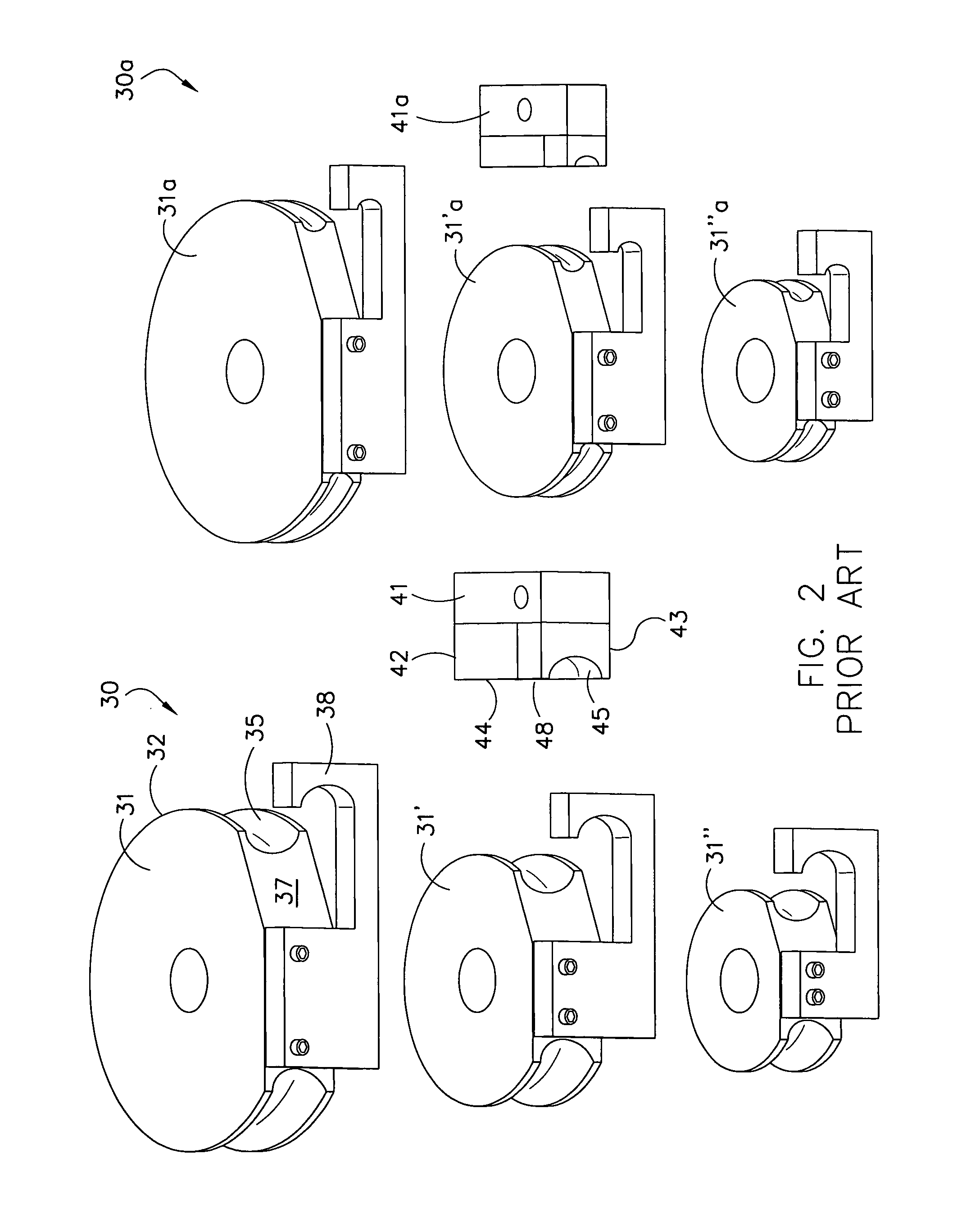

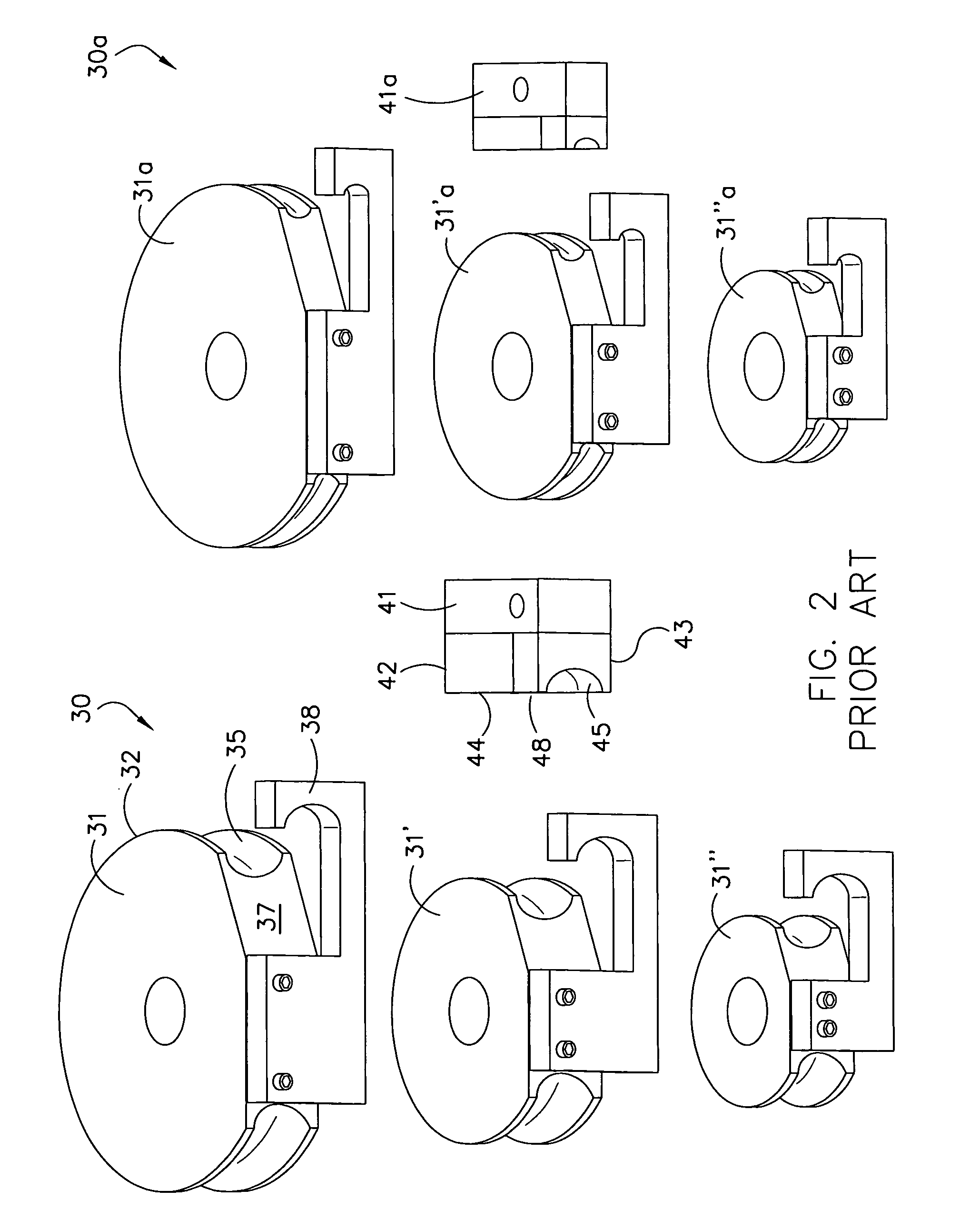

Techniques for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and sheet therefor

InactiveUS20040134250A1High precisionImprove bending strengthAdditive manufacturing apparatusConstruction materialManufacturing technologyEngineering

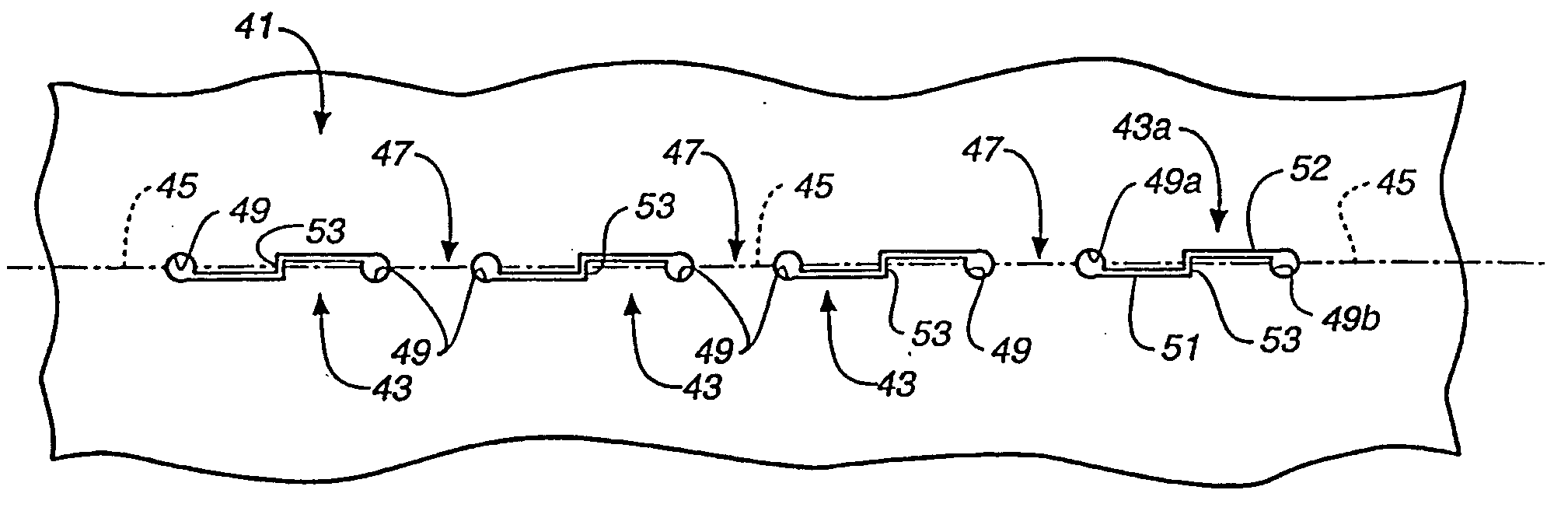

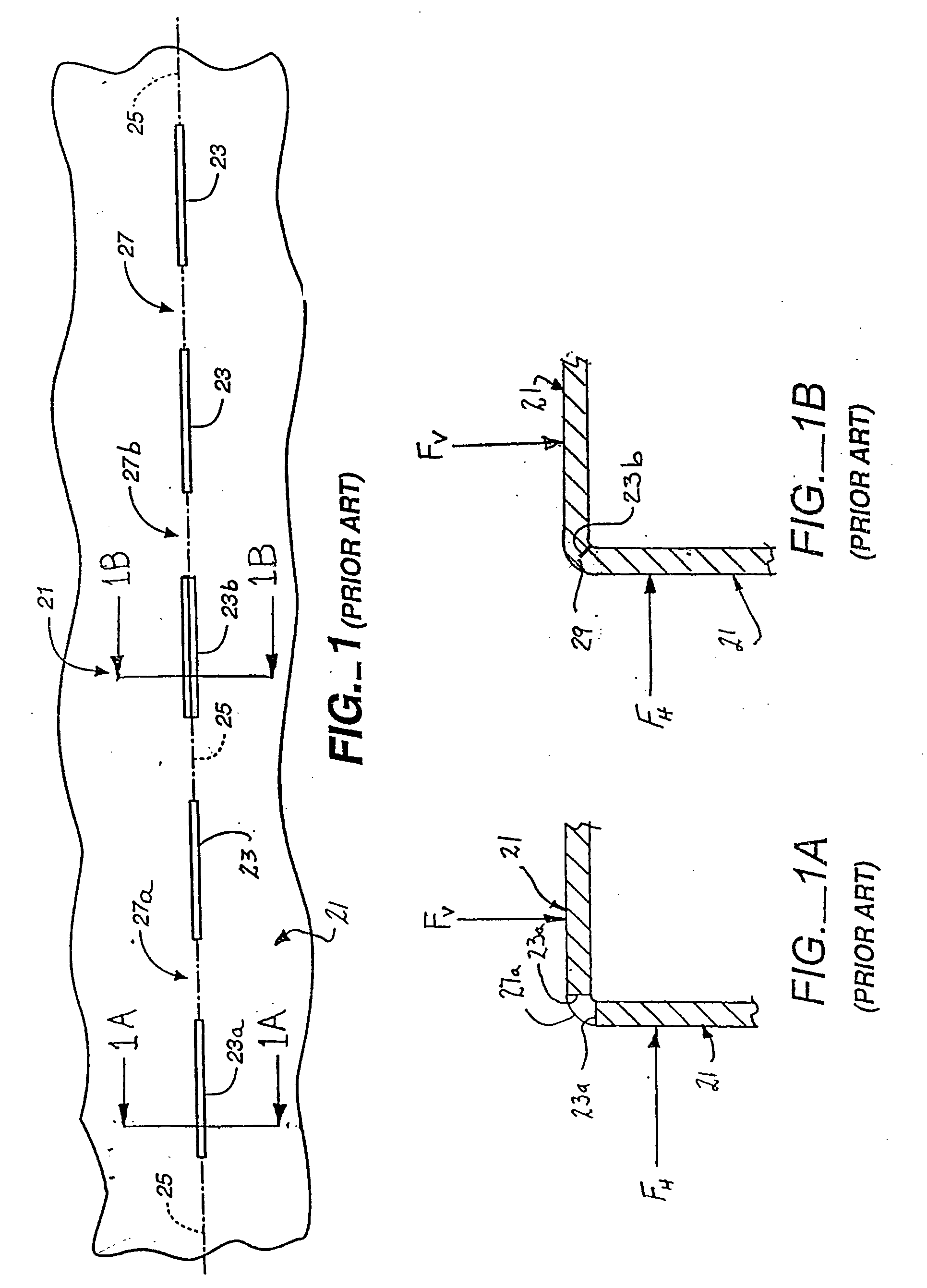

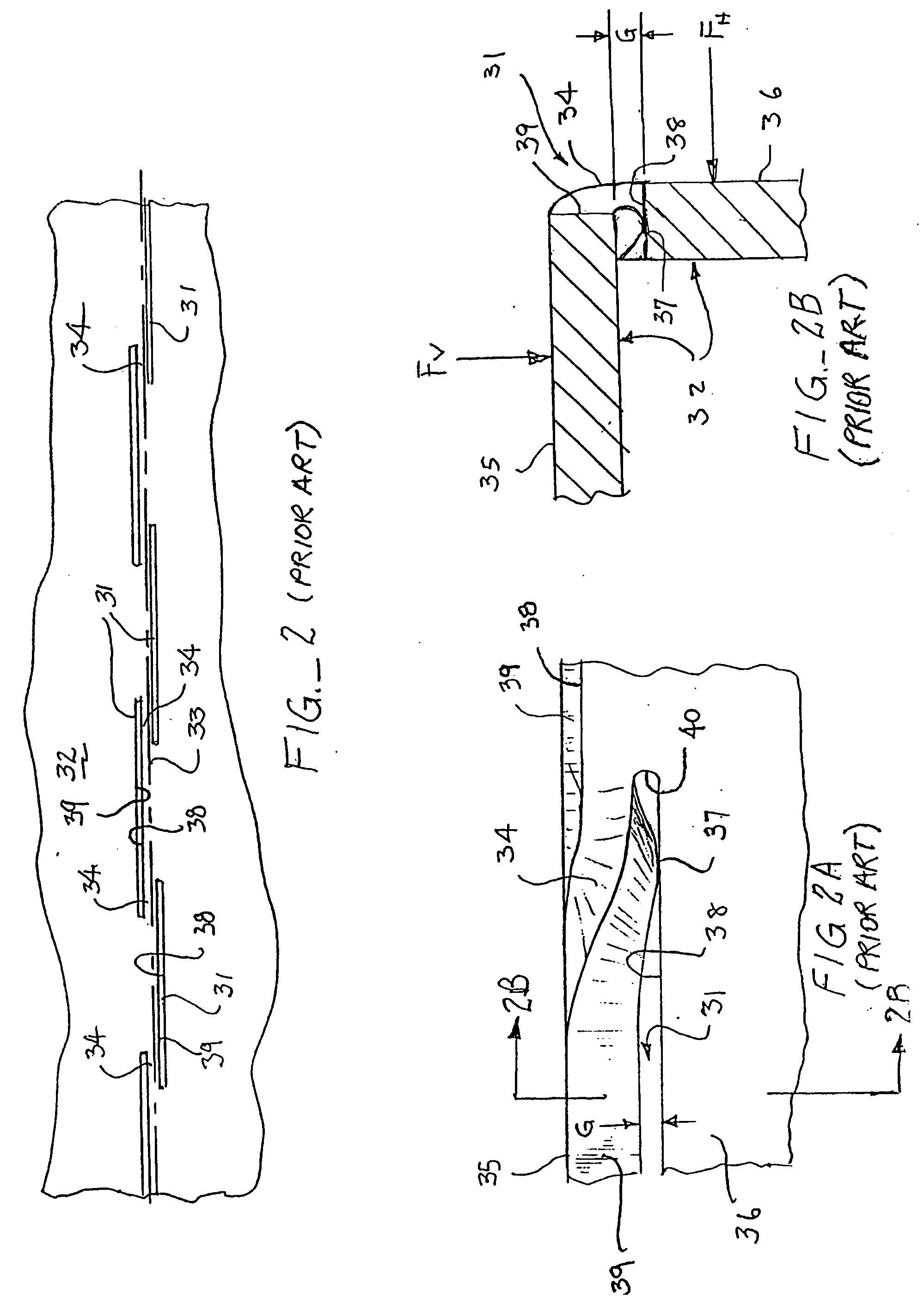

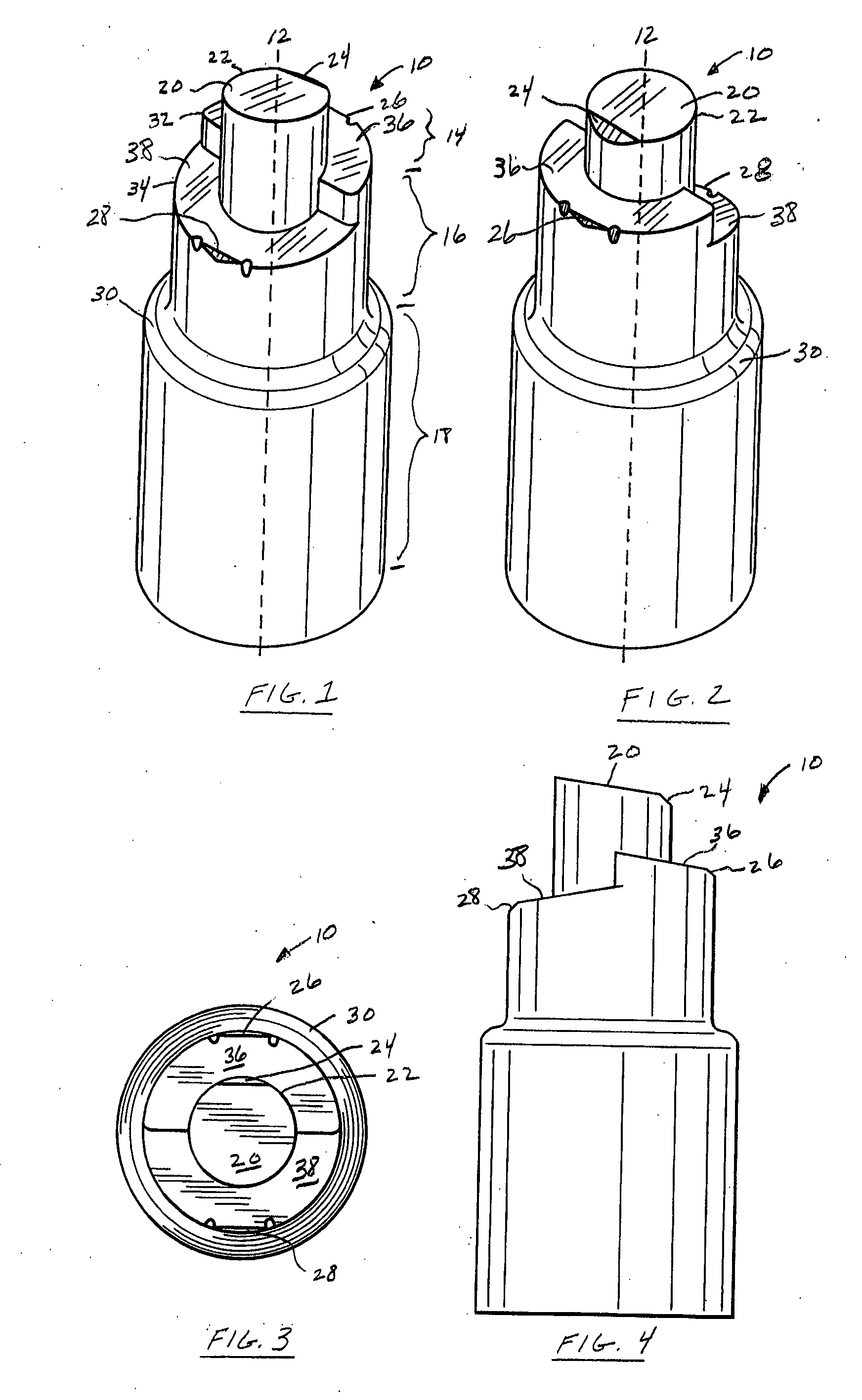

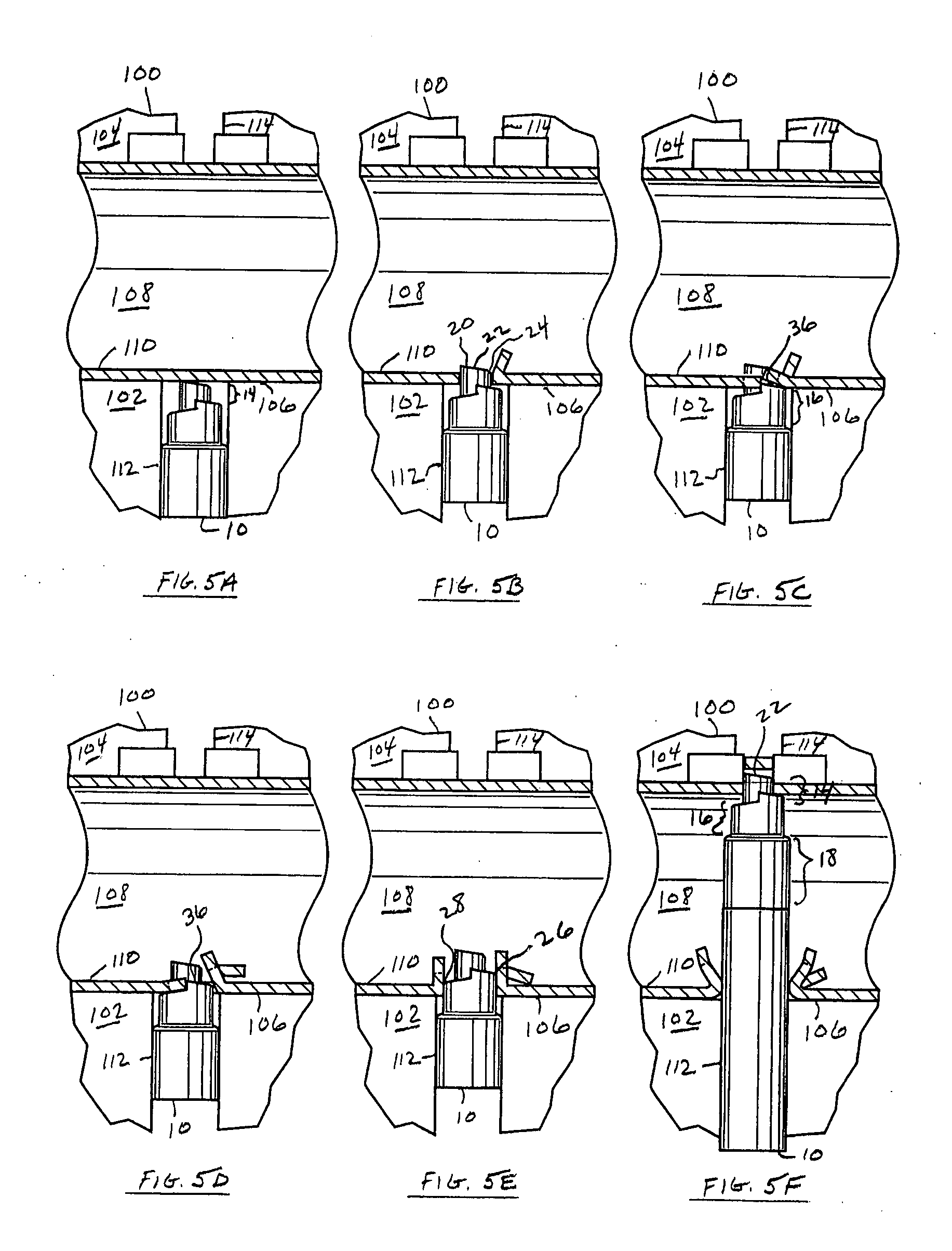

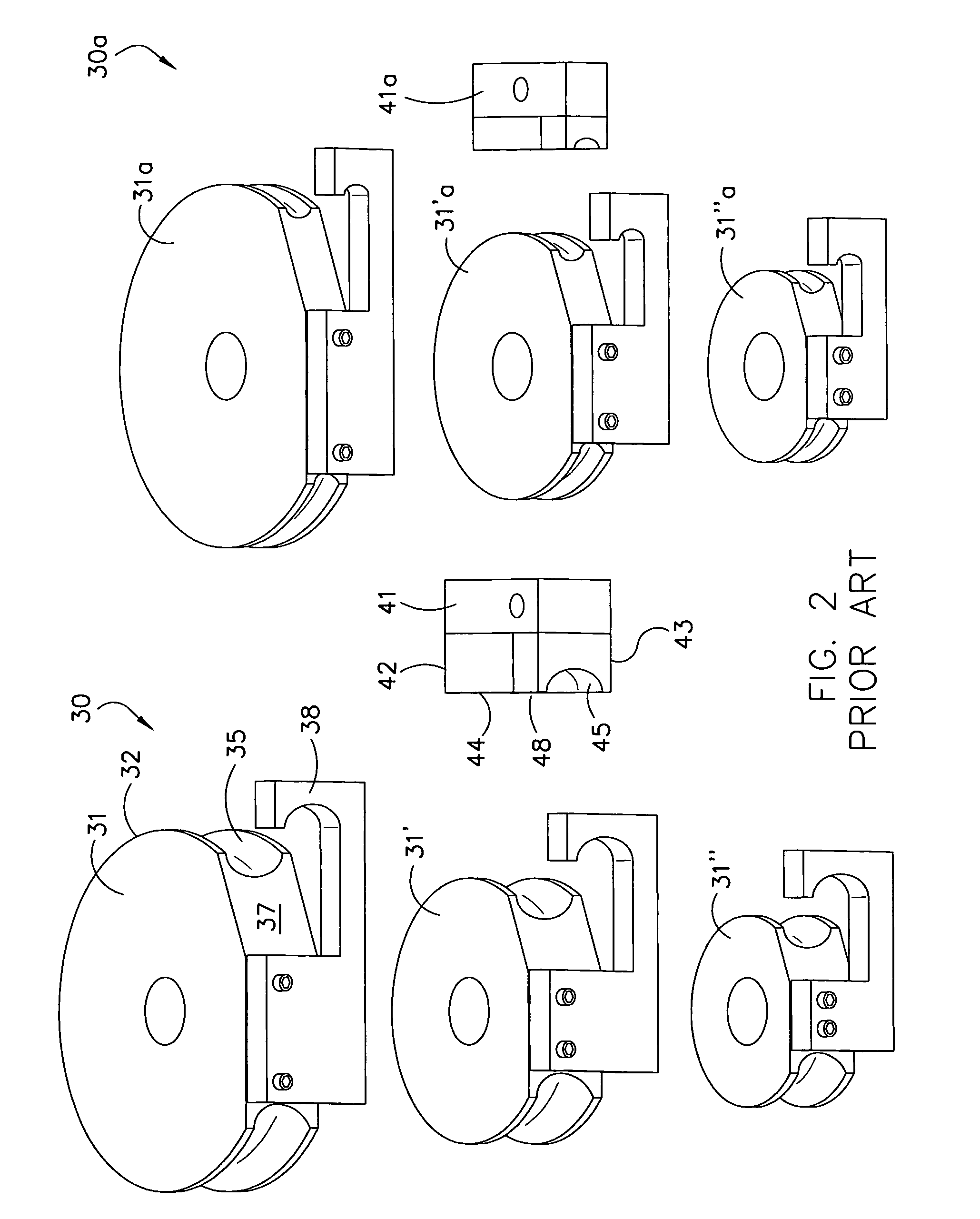

A process for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and a sheet therefore. The techniques include methods for precision bending of a sheet of material (41, 241, 341, 441, 541) along a bend line (45, 245, 345, 445,543) and a sheet of material formed with bending strap-defining structures, such as slits or grooves (43, 243, 343, 443, 542), are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves (43, 243, 343, 443, 542) through the sheet of material in axially spaced relation to produce precise bending of the sheet (41, 241, 341, 441,541) when bent along the bend line (45, 245, 345, 445, 543). The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges (257, 457) to be engaged and supported on faces (255, 455) of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line (45, 245, 345, 445, 543). Several slit embodiments (43, 243, 343, 443, 542) suitable for producing edge-to-face engagement support and precise bending are disclosed, as is the use of the slit sheets to produce various three-dimensional structures and to enhance various design and fabrication techniques.

Owner:IND ORIGAMI INC CA US

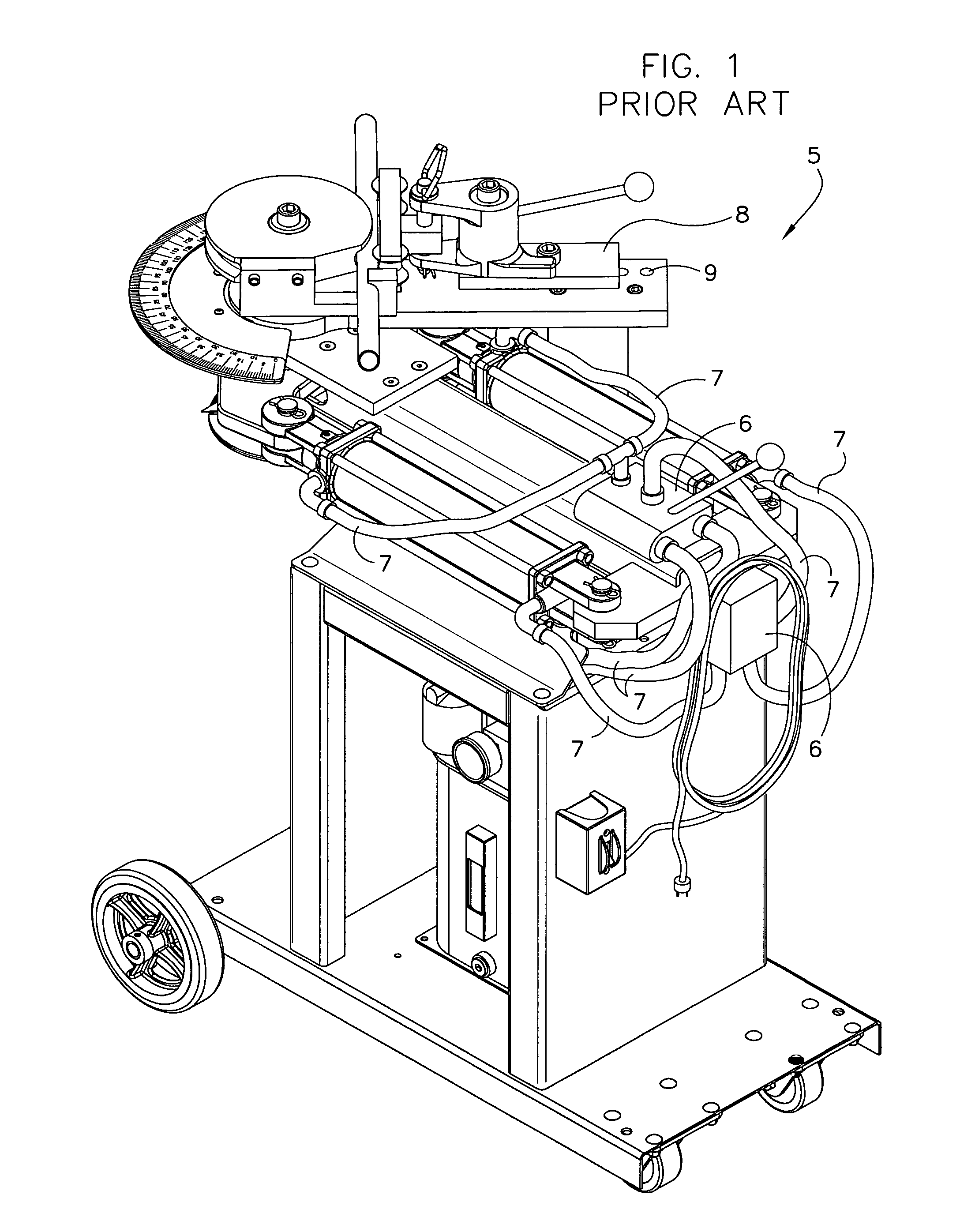

Rotary draw tube bender

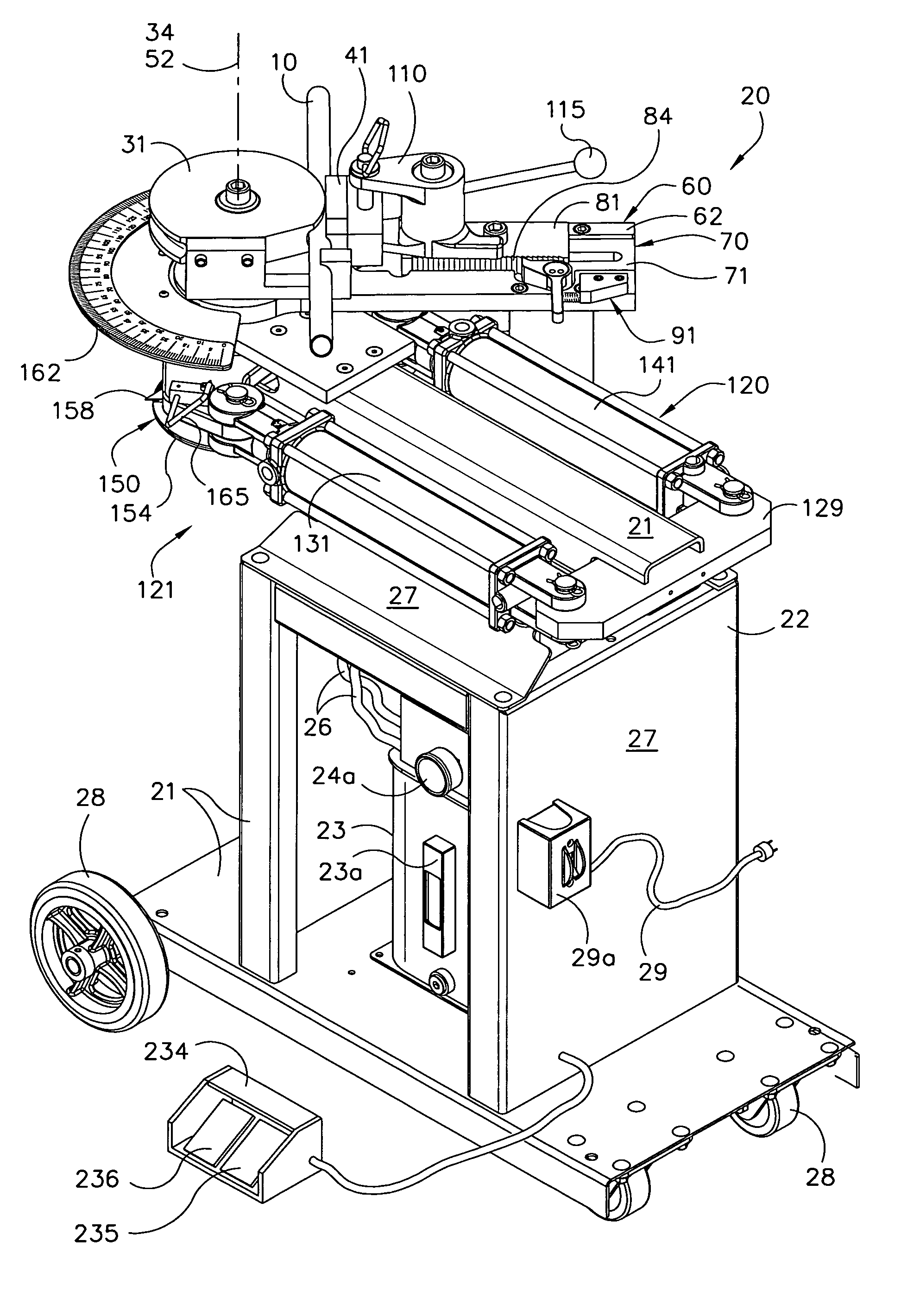

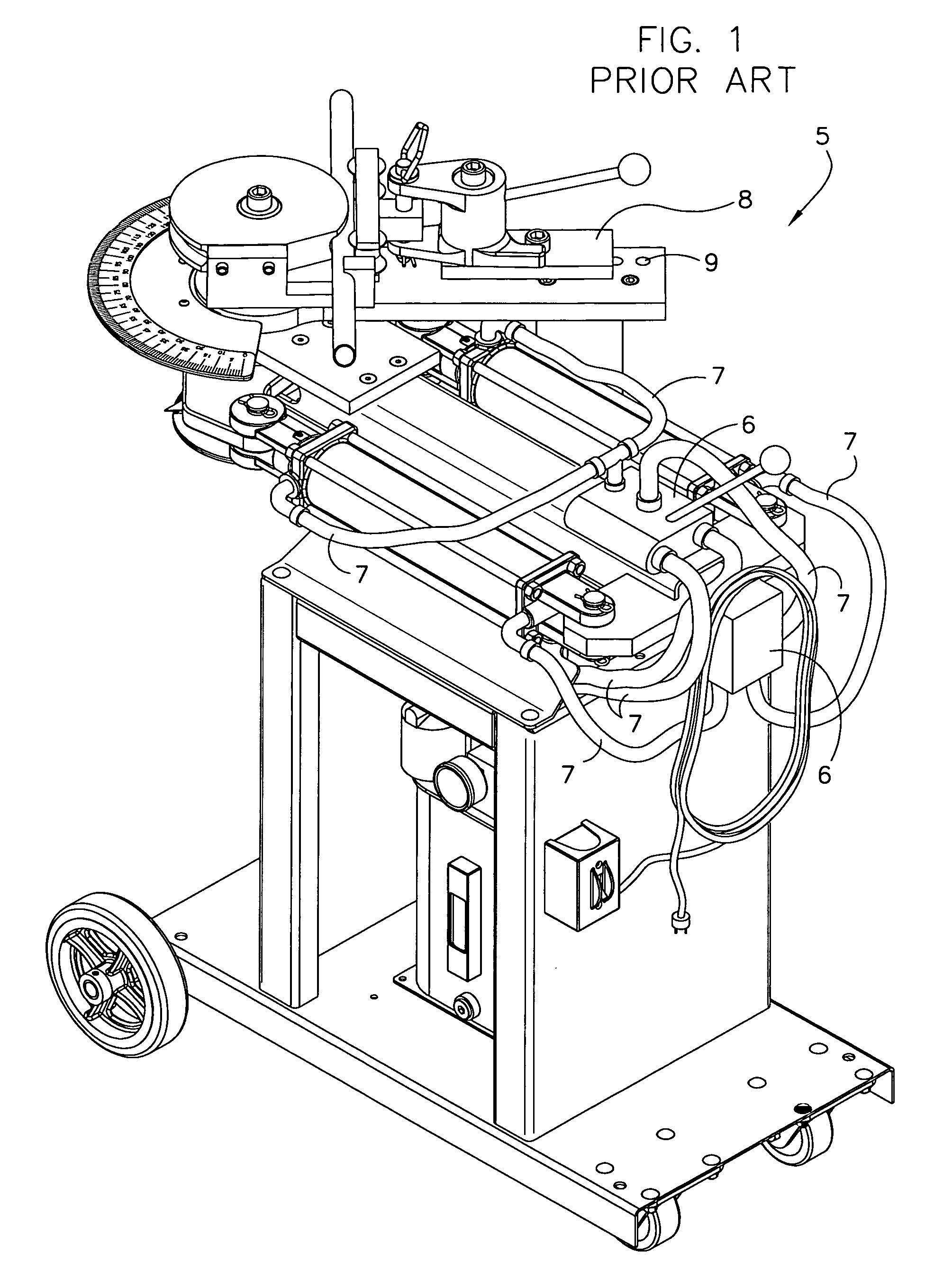

ActiveUS7380430B1Precise bendingAccurate settingShaping toolsForging/hammering/pressing machinesProtractorControl system

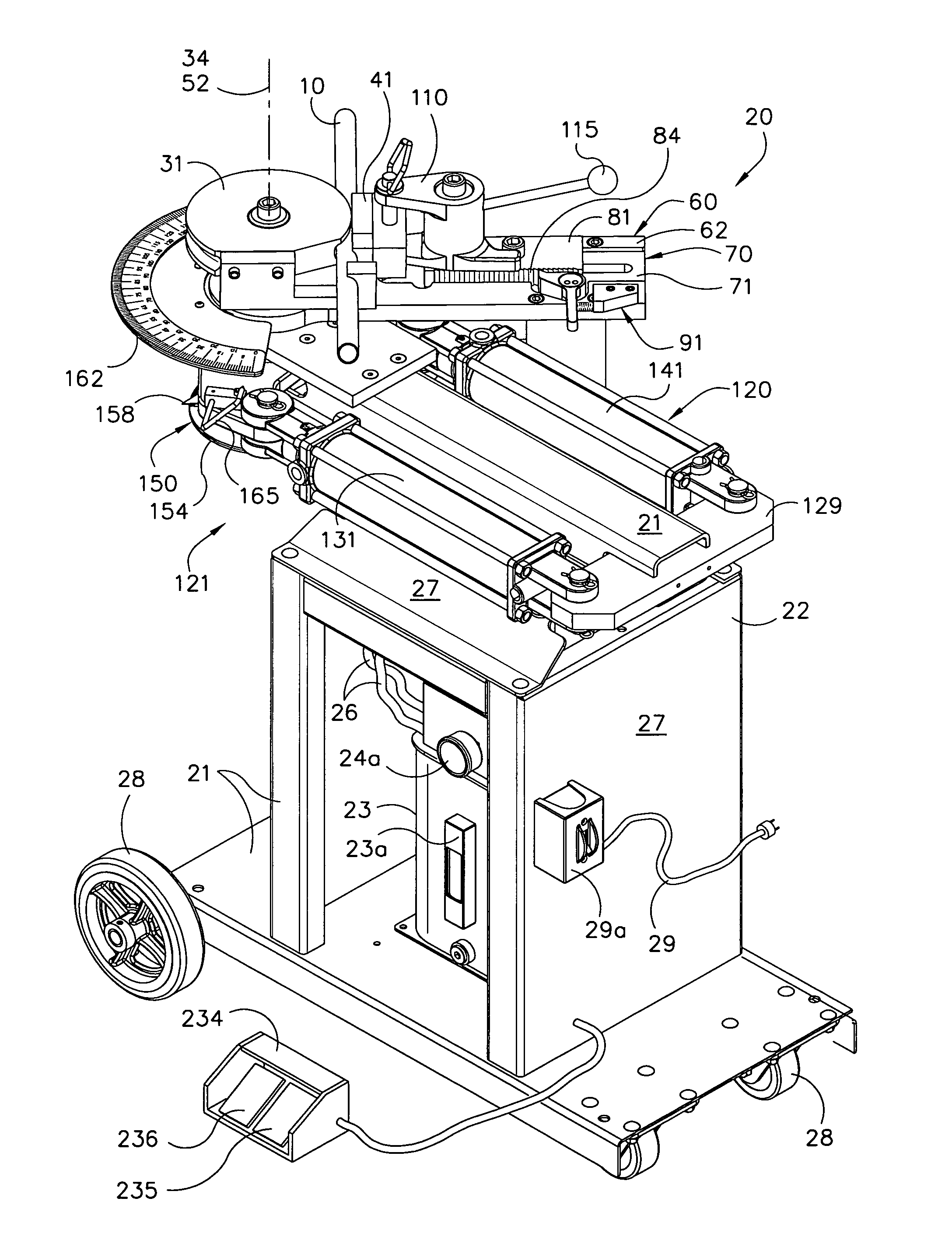

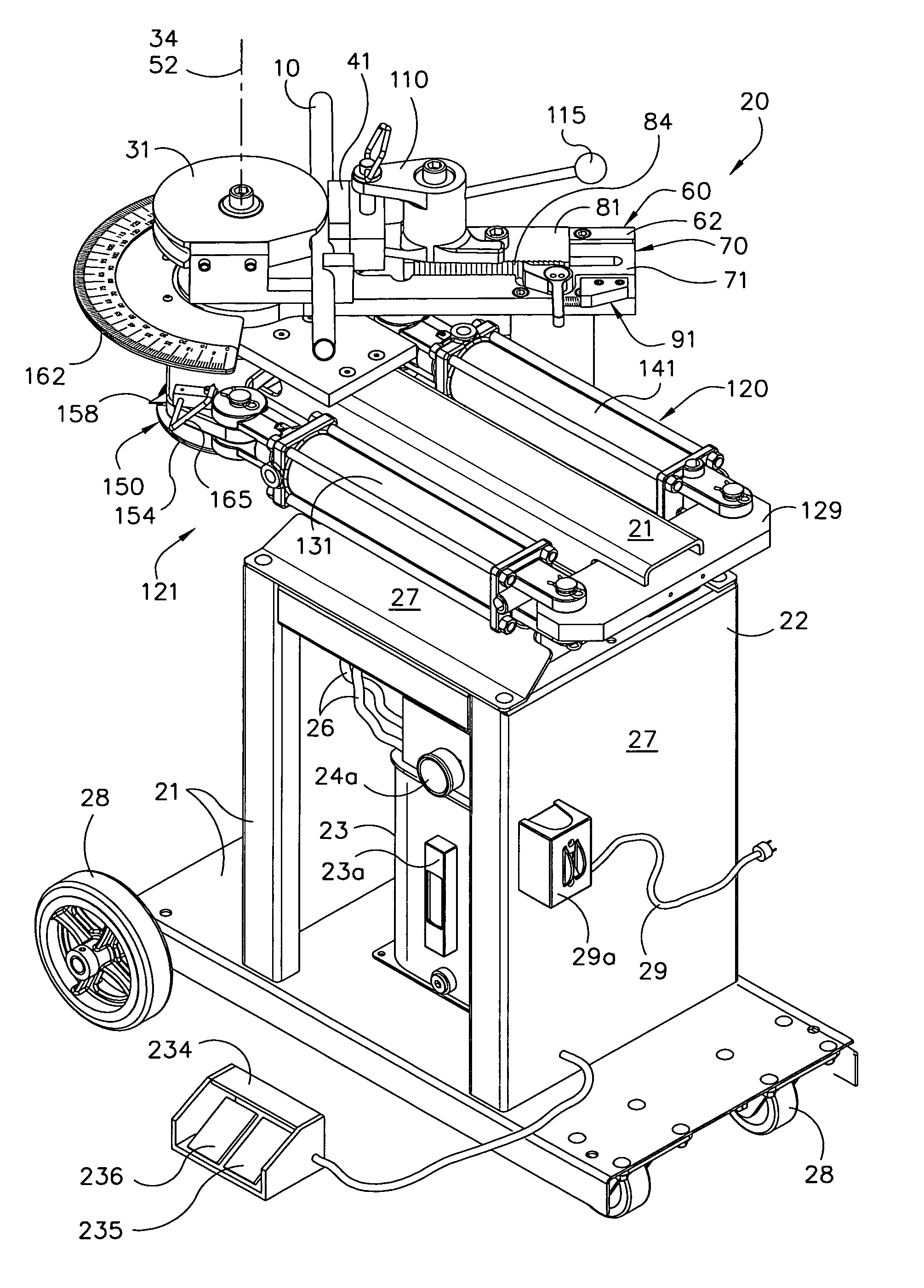

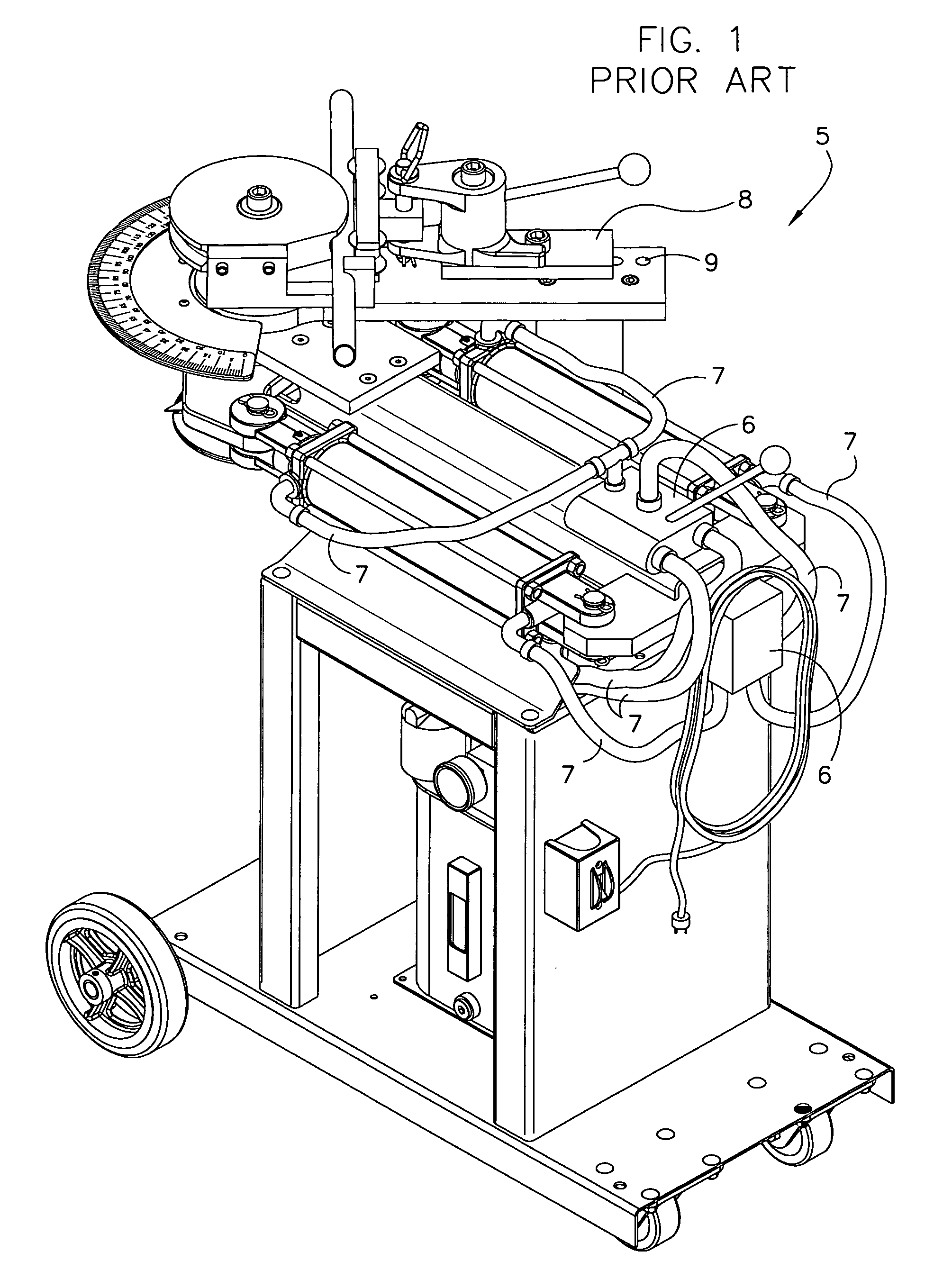

The invention is a rotary draw bending machine and process for bending materials such as tubes or pipes into precise bends. A spindle holds a bending die, and a radial arm holds a counter-die. The spindle and arm are simultaneously rotated in opposite directions by a dual hydraulic drive controlled by an electro-hydraulic control system with foot pedal controls. The bend angle is preset by a protractor-like dial and limit switch mechanism. The radial arm has a slide track to align the counter-die with the bending die. The ratchet mechanism has teeth to allow incremental advancement of the counter-die when aligning it with its bending die to accurately set the gap between the dies. The machine is used with a wide variety of dies to bend a wide variety of workpiece diameters. The ratchet mechanism preferably includes a fine tuning device to provide an infinite range of alignment positions.

Owner:JPW IND

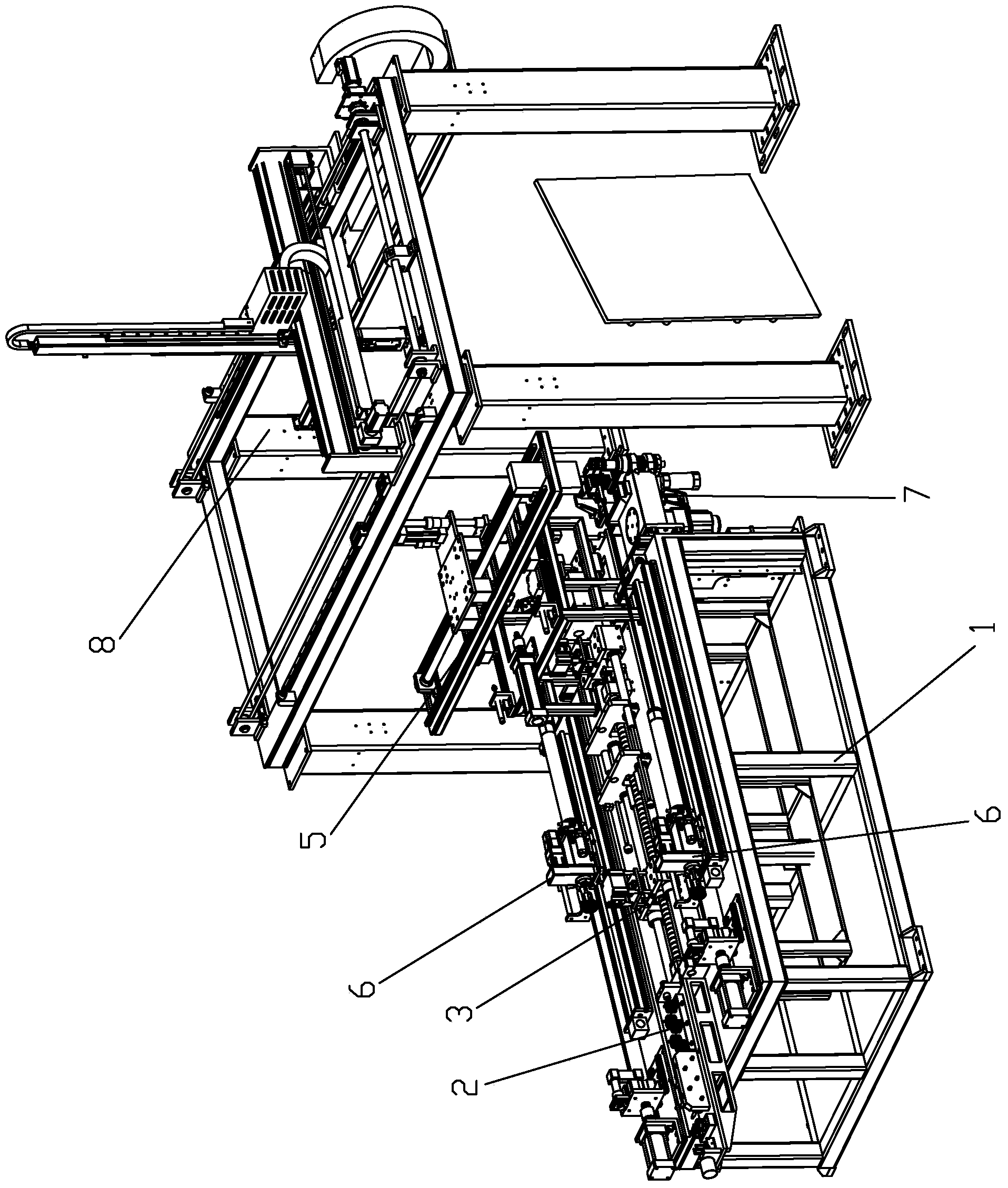

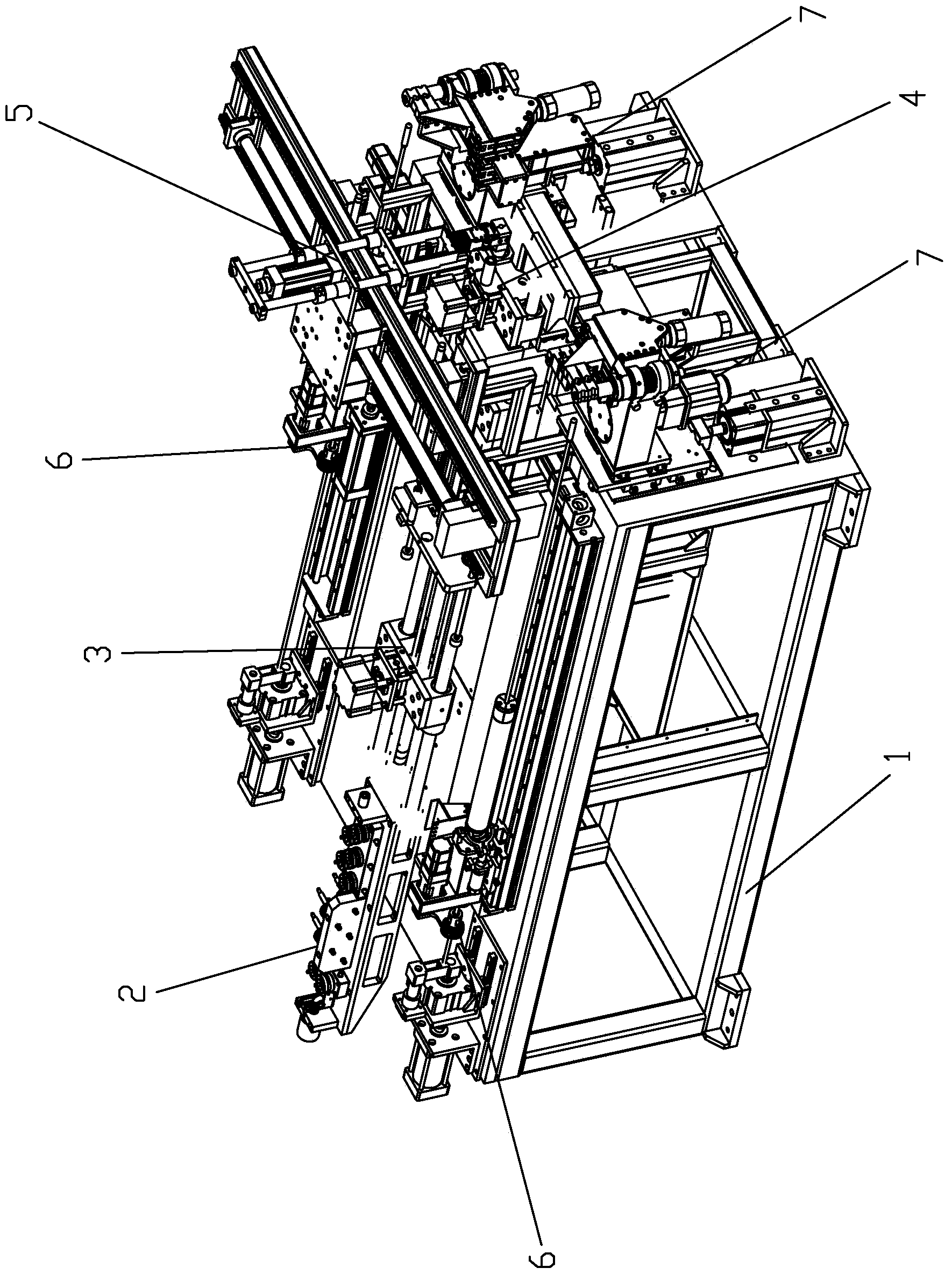

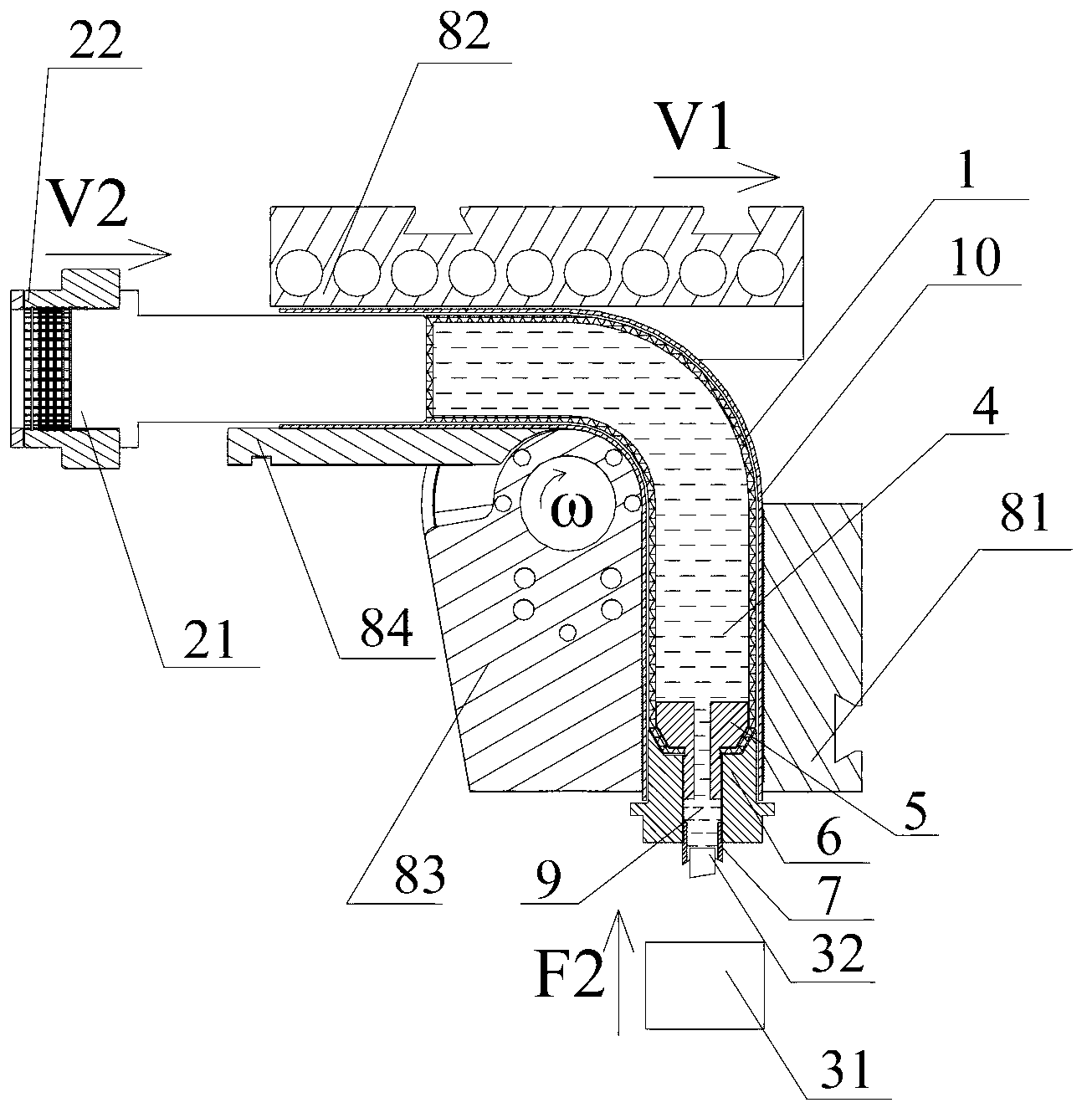

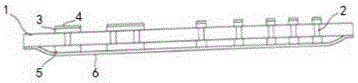

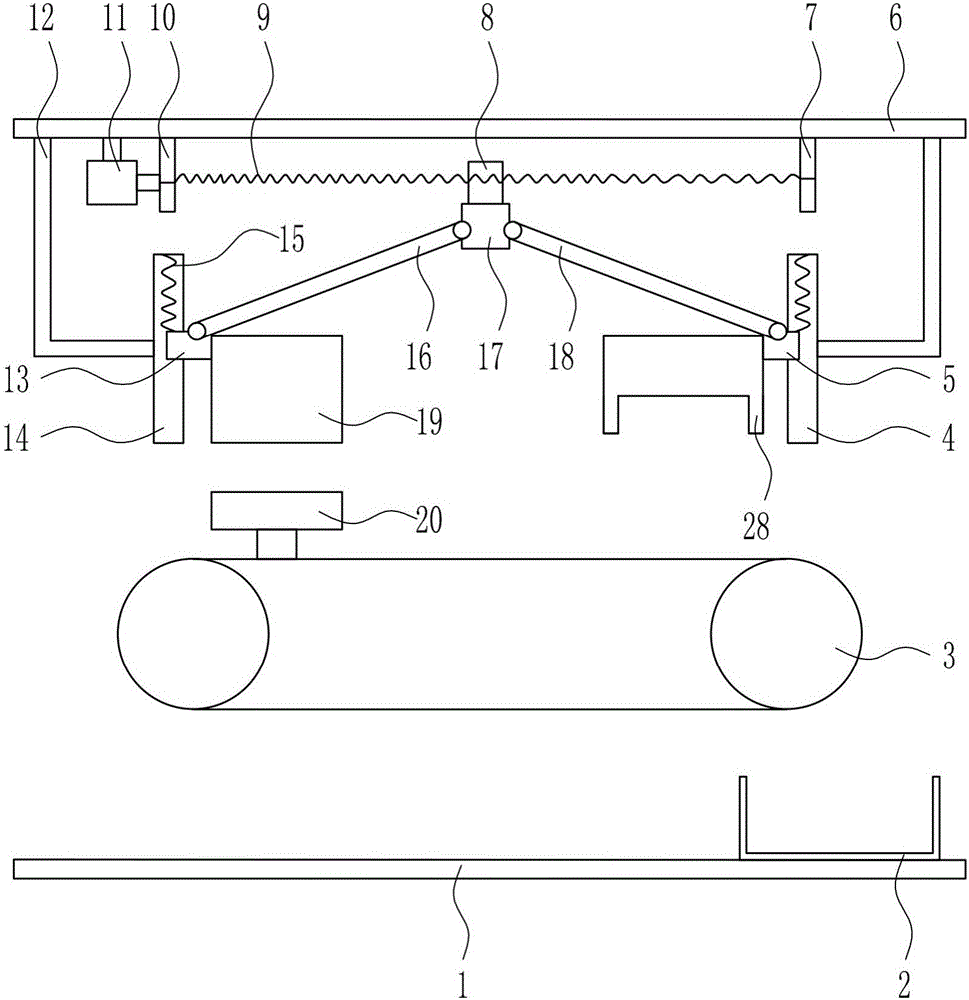

Pipe bending machine

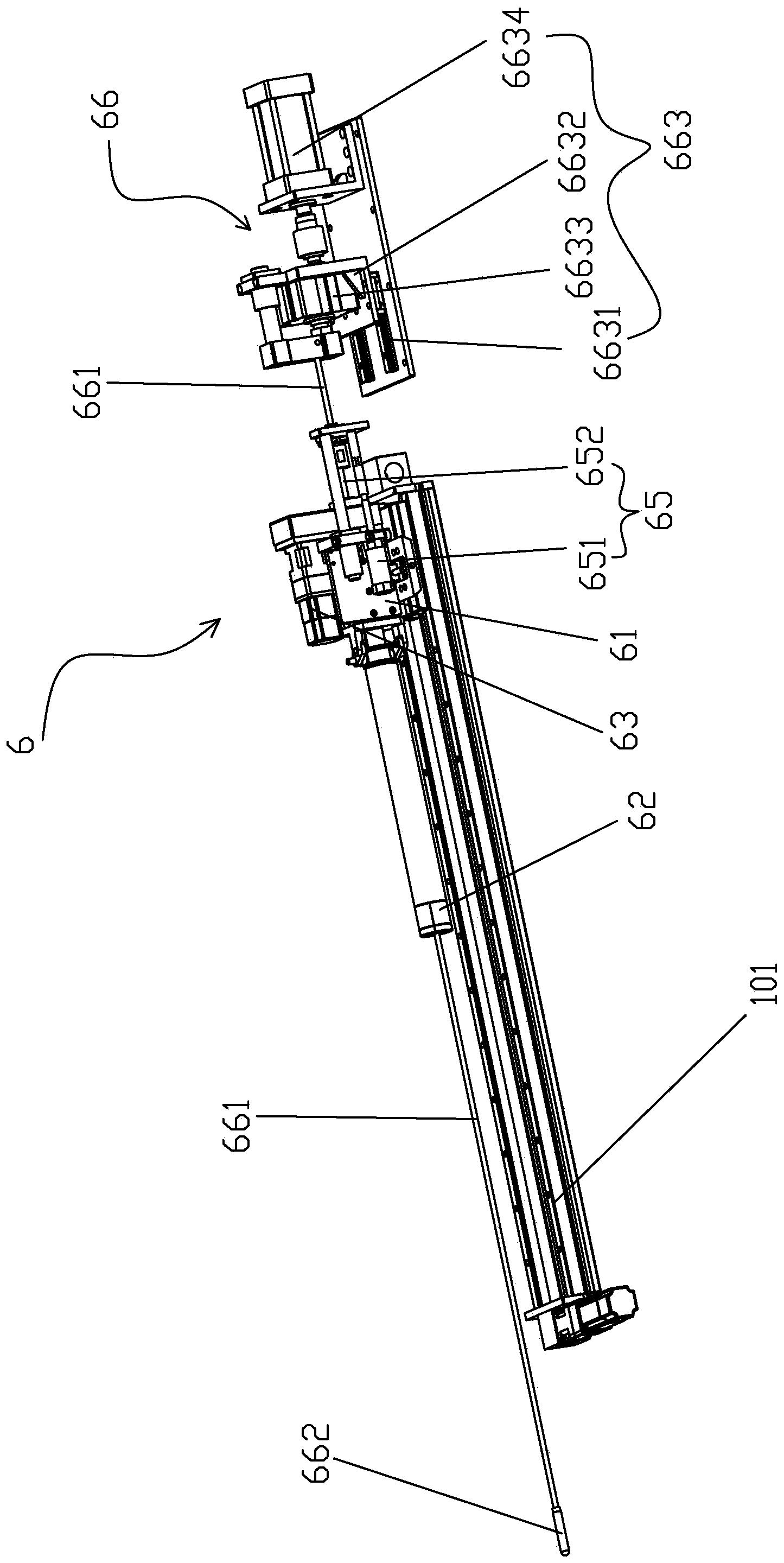

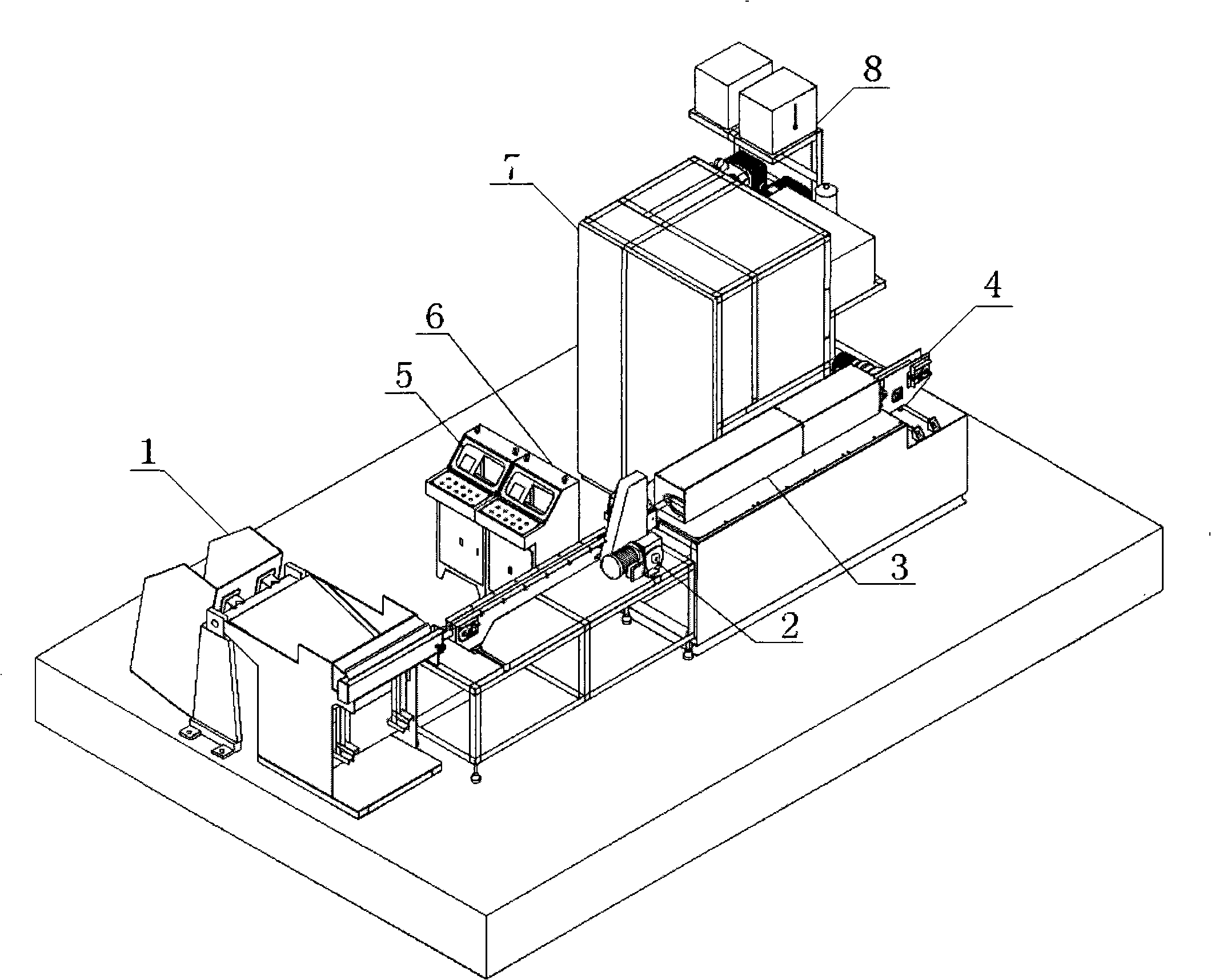

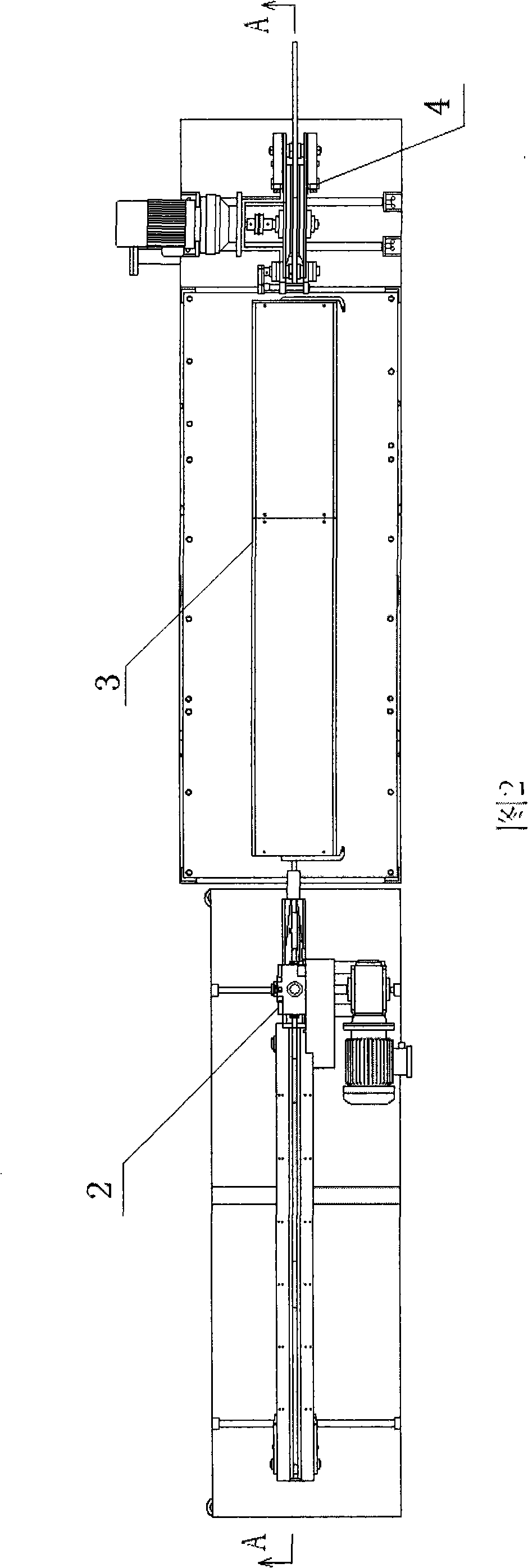

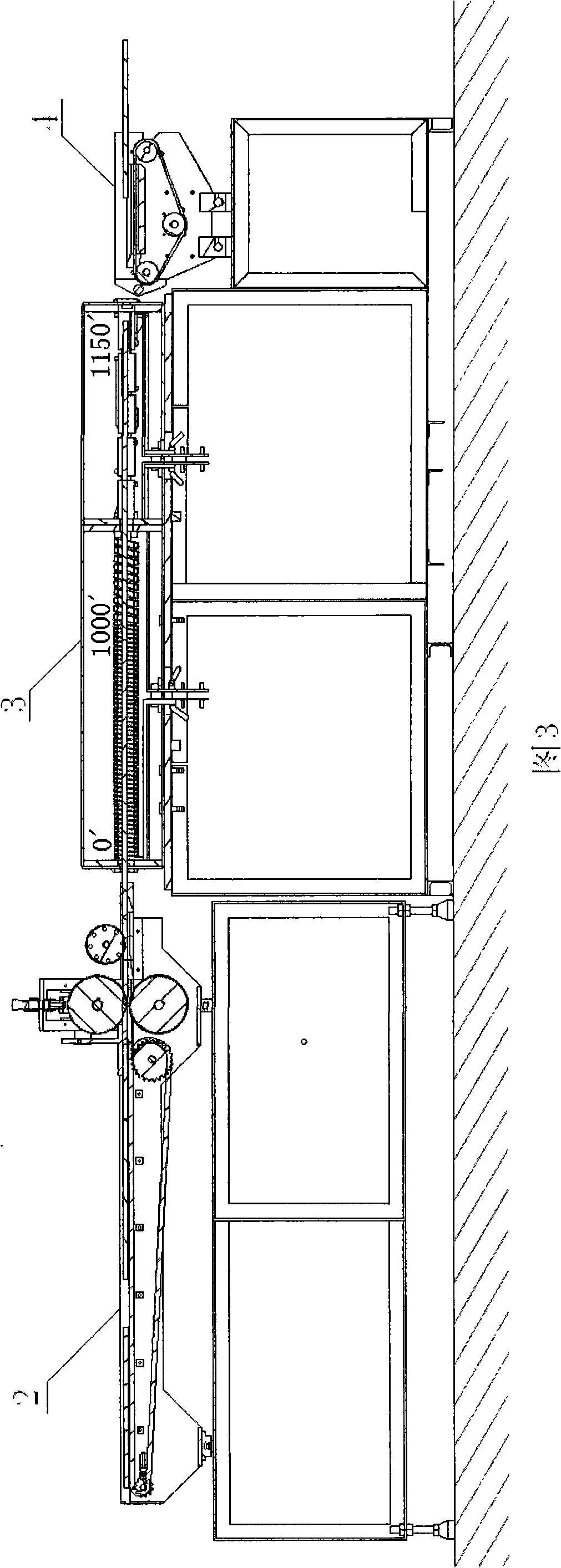

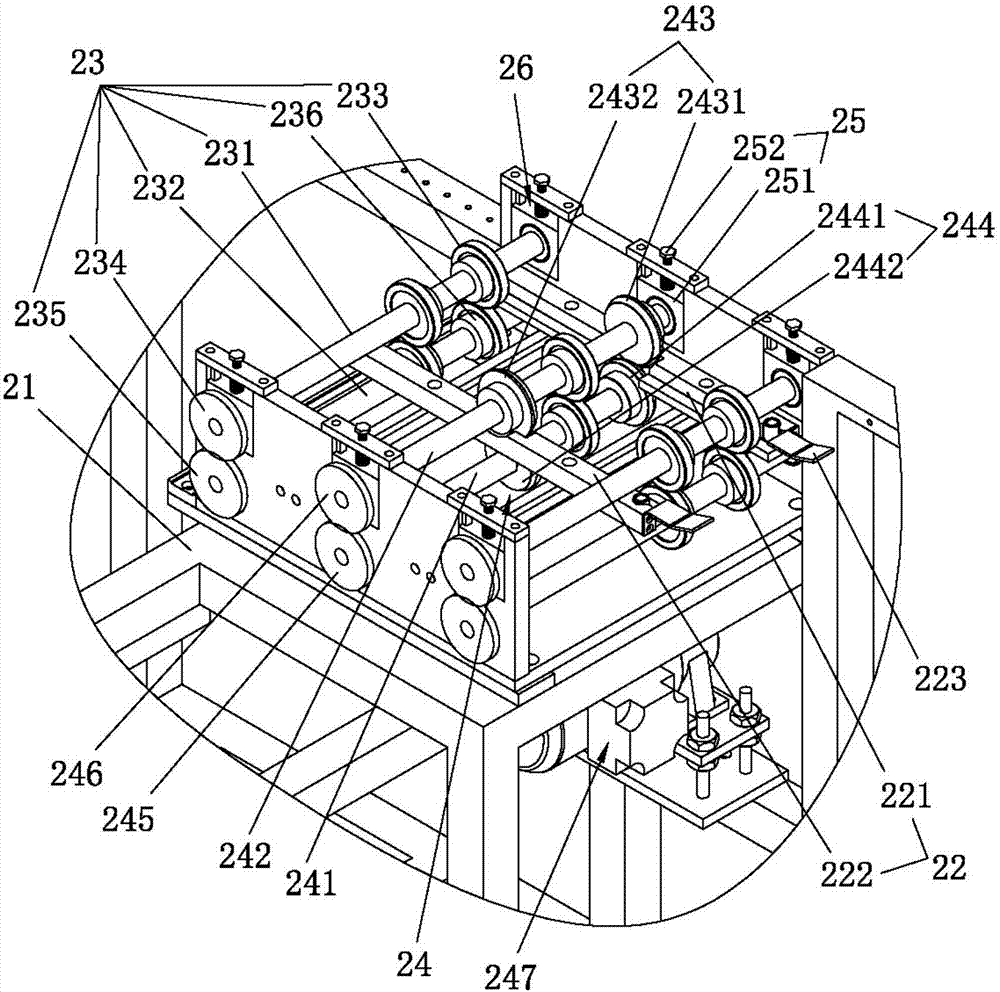

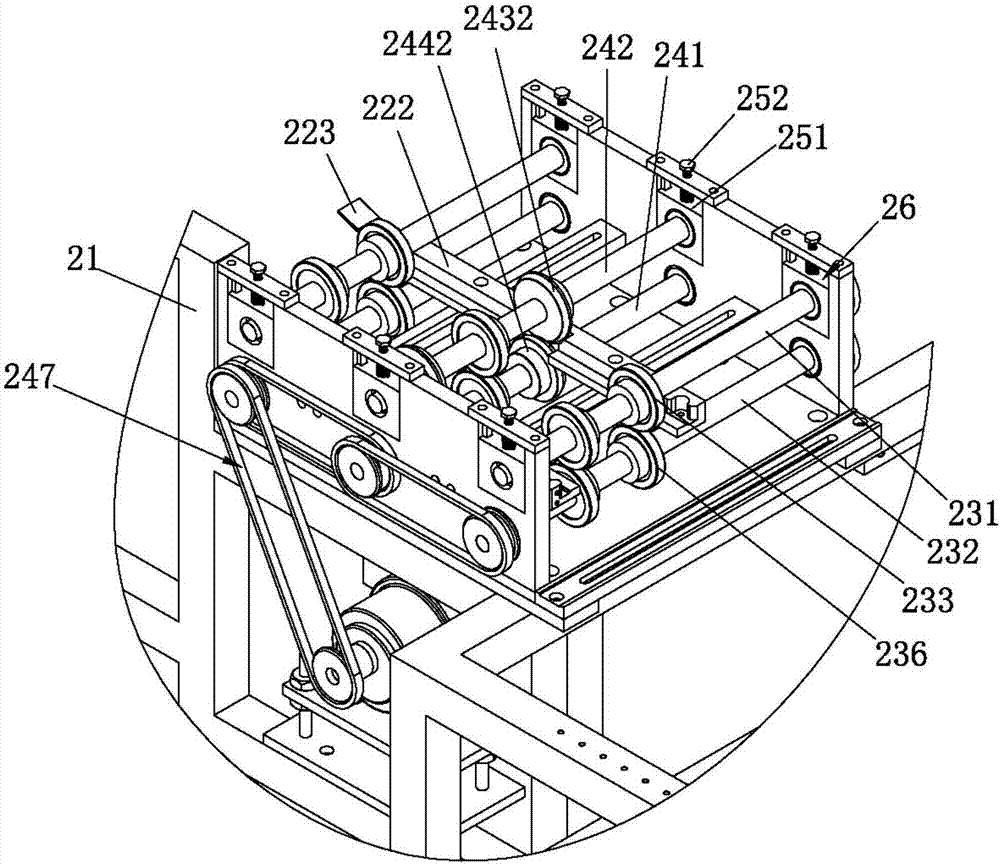

ActiveCN103878267AImprove work efficiencySave human effortShaping toolsEjection devicesManipulatorBend Material

The invention discloses a pipe bending machine which comprises a rack. A straightening mechanism is arranged on the rack, a feeding mechanism is arranged at an output end of the straightening mechanism, a cutting mechanism is arranged at an output end of the feeding mechanism, a moving mechanism is arranged at an output end of the cutting mechanism and can move material pipes cut by the cutting mechanism to a pipe bending feeding mechanism arranged beside the feeding mechanism, a bending mechanism capable of bending the material pipes fed by the pipe bending feeding mechanism is arranged at an output end of the pipe bending feeding mechanism, a discharging mechanism for discharging is arranged at an output end of the bending mechanism, the pipe bending feeding mechanism comprises a sliding rail, a feeding seat is arranged on the sliding rail, a rotating clamping head, a rotating positioning motor and a clamping cylinder driving the rotating positioning head to clamp the material pipes is arranged on the feeding seat, and a pushing device capable of pushing the bent material pipes out of the rotating clamping head is arranged on the feeding seat. By the pipe bending machine, small-specification bend material pipes that a discharging manipulator cannot grab can be pushed out of the pipe bending machine to complete automatic discharging, so that working efficiency is improved, manpower is saved, and production cost is lowered.

Owner:OMS MASCH CO LTD

Rotary draw tube bender

The invention is a rotary draw bending machine and process for bending materials such as tubes or pipes into precise bends. A spindle holds a bending die, and a radial arm holds a counter-die. The spindle and arm are simultaneously rotated in opposite directions by a dual hydraulic drive controlled by an electro-hydraulic control system with foot pedal controls. The bend angle is preset by a protractor-like dial and limit switch mechanism. The radial arm has a slide track to align the counter-die with the bending die. The ratchet mechanism has teeth to allow incremental advancement of the counter-die when aligning it with its bending die to accurately set the gap between the dies. The machine is used with a wide variety of dies to bend a wide variety of workpiece diameters. The ratchet mechanism preferably includes a fine tuning device to provide an infinite range of alignment positions.

Owner:JPW IND

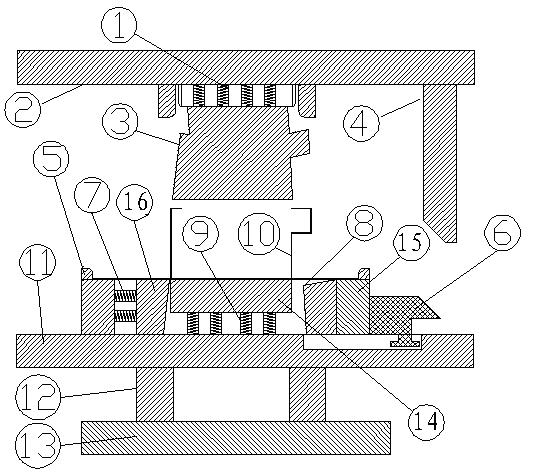

Double stroke lateral-push sliding mechanism bending die

The invention relates to a lateral-push sliding block mechanism bending die which comprises an upper die seat, a lower die seat matched with the upper die seat, and an upper stripper arranged on the upper die seat, wherein a lower die plate used for the placement of bending material pieces is arranged on the lower die seat, a lower cushion block and a lower bearing plate are mounted at the bottom of the lower die seat, the lower cushion block is arranged between the lower die seat and the lower bearing plate, and a bending block used for bending material pieces to be bent, and a lateral-push sliding block for driving the bending block to move are arranged on the lower die seat; a bending and leaning knife used for extruding the lateral-push slide block to move is further mounted on the upper die seat during the die assembly of the upper die seat and the lower die seat, an upper die spring is further arranged between the upper stripper and the upper die seat, and a lower die spring is further arranged between the lower die plate and the lower die seat. The lateral-push sliding block mechanism bending die provided by the invention has a simple structure, and lowers and reduces the costs for die development and die obsolete materials. The working performance is improved greatly, actions in die replacement to punching equipment are reduced, and the processing efficiency of the equipment is improved.

Owner:KUSN SHENGTAI ELECTROMECHANICAL MFG

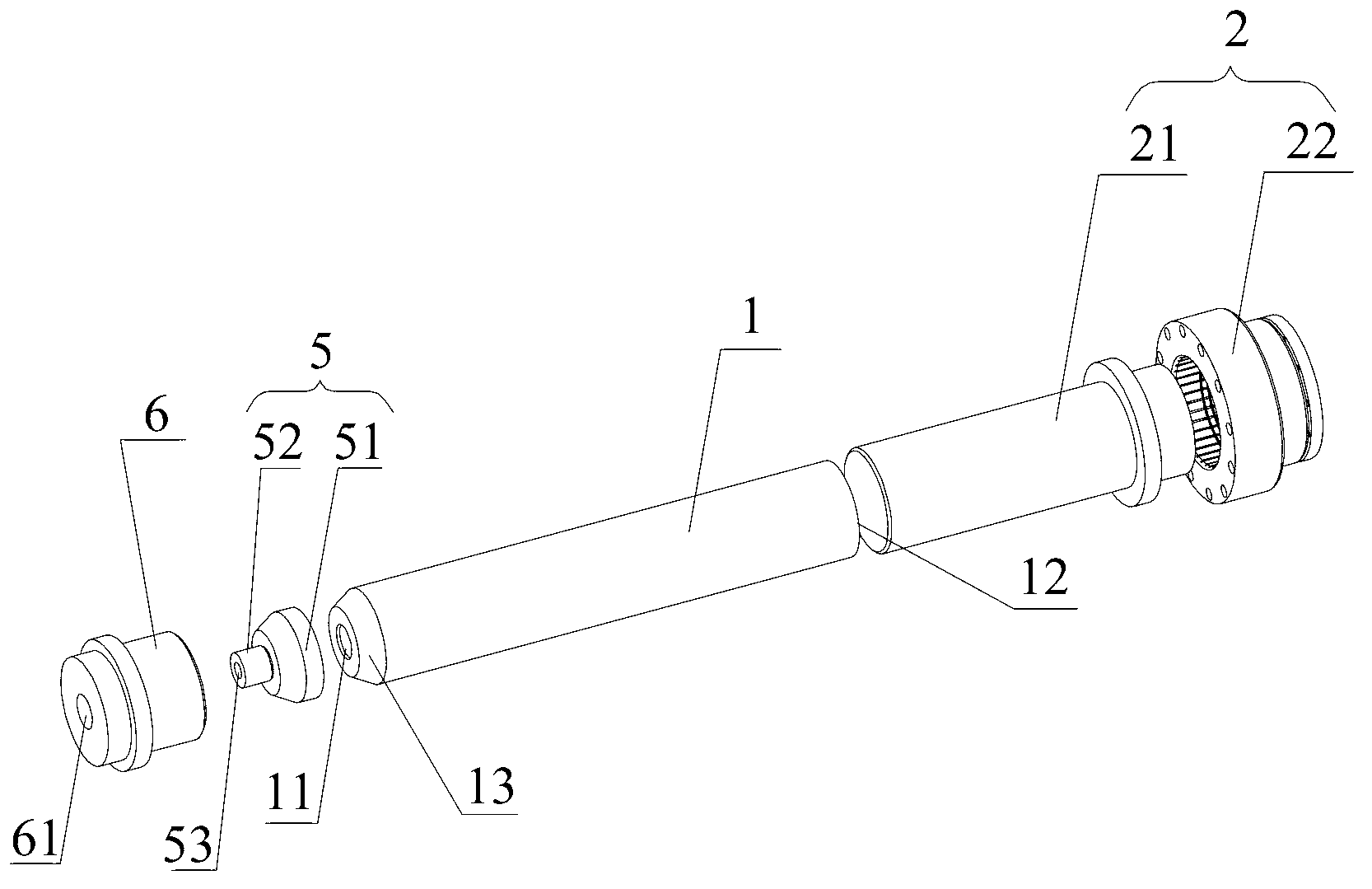

Tubular product bending internal pressing supporting device and tubular product bending method

The invention discloses a tubular product bending internal pressing supporting device and a tubular product bending method. The tubular product bending material pressing supporting device comprises a hollow cylindrical rubber bag, an ejecting mechanism and an infusion and pressurization mechanism, wherein a through hole is formed in one end of the rubber bag and the other end of the rubber bag is sealed, the ejecting mechanism abuts against the outer side of the sealed end of the rubber bag, and the infusion and pressurization mechanism is arranged at the end, with the through hole, of the rubber bag. The infusion and pressurization mechanism comprises a pressurization cylinder provided with a piston rod and a sealing component, the sealing component is clamped at the side, with the through hole, of the rubber bag in a sealing mode, a liquid flowing channel is arranged at the center of the sealing component, the pressurization cylinder is connected with the liquid flowing channel in a sealing mode through a cylindrical connecting body, and the piston rod stretches into the liquid flowing channel through the cylindrical connecting body; liquid medium in the rubber bag pushes a sealing plug to pressurize through the piston rod of the pressurization cylinder to drive the rubber bag to expand in the radial direction. The tubular product bending internal pressing supporting device is matched with the inner wall of a tubular product in a self-adaptation mode, contact is even, the inner cavity of the tubular product is prevented from being scratched and wrinkling, and manufacturing and using cost can be greatly reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

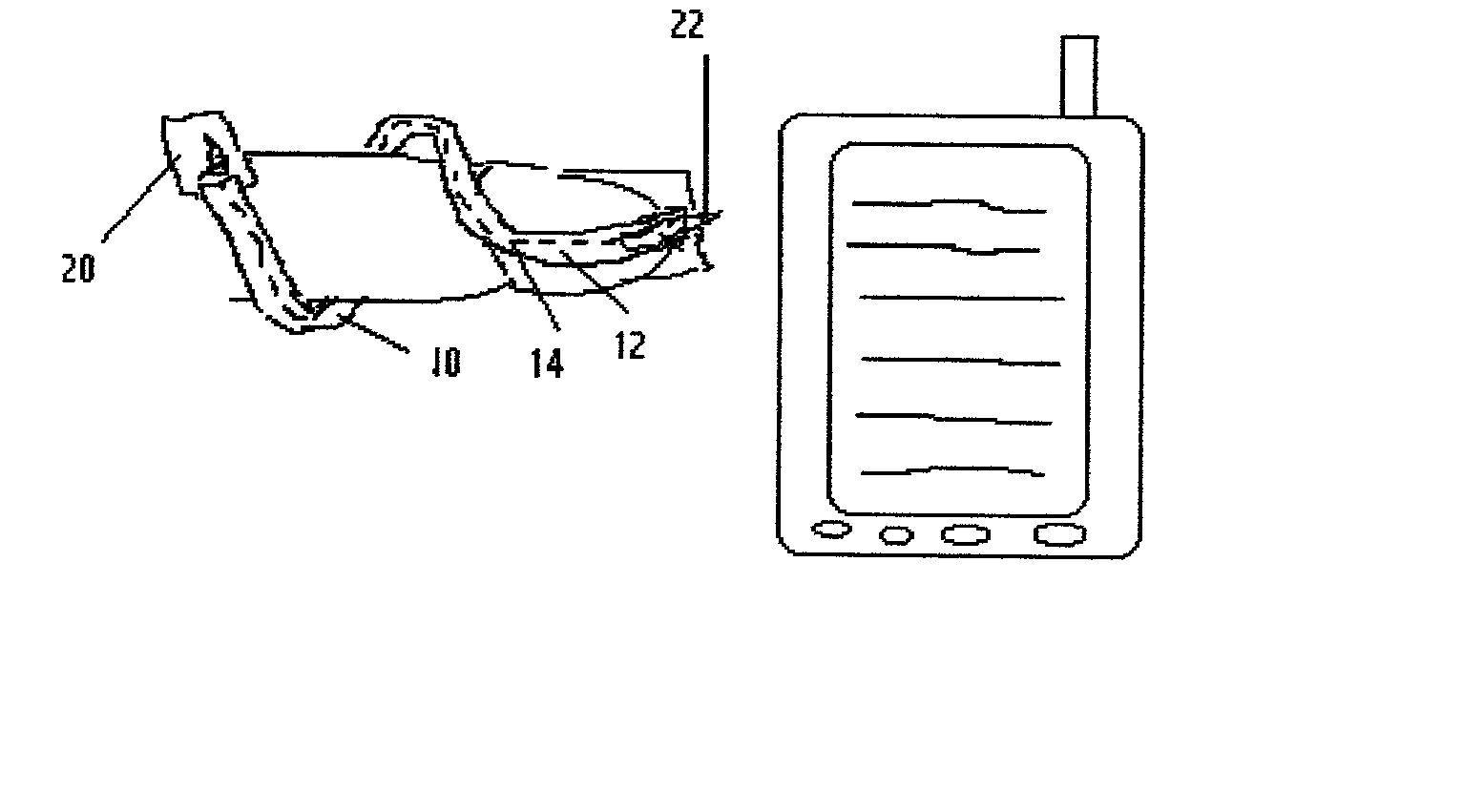

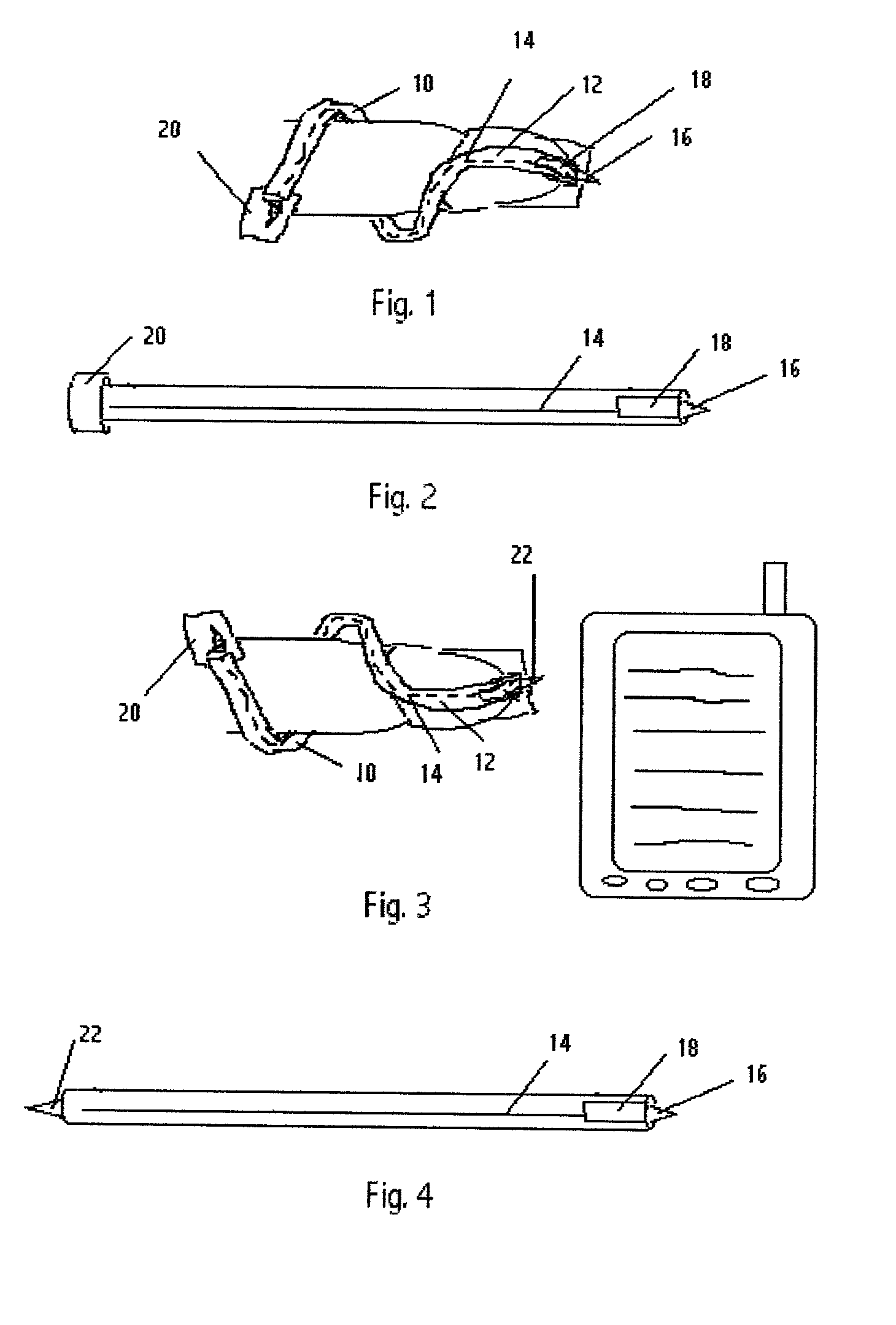

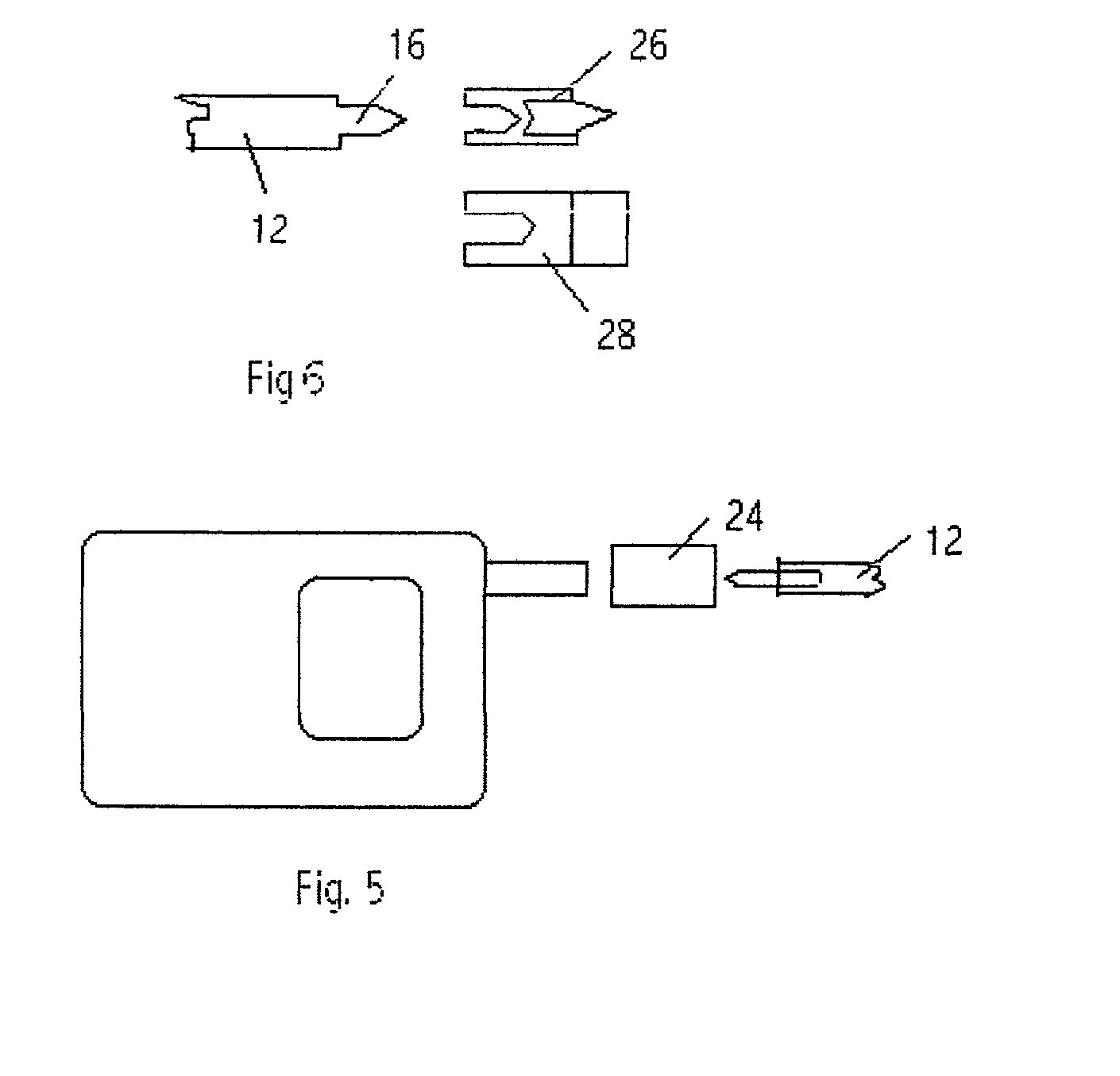

Fingertip pen/stylus

InactiveUS20020034412A1Prevent accidental markingLiquid surface applicatorsCarpet cleanersEngineeringStructural engineering

A multi-purpose fingertip pen / stylus comprising a flexible shaft having first and second ends made of a bendable material, which retains a twisted shape, said shaft sized of sufficient length to wrap and secure about the fingertip of a writing digit or to be used in a straightened position as a conventional pen; the first end adapted as a stylus tip for use with pressure sensitive computer screens, and the second end adapted as a writing tip to extend sufficiently beyond the fingertip of the writing digit stylus to contact and write on a writing surface.

Owner:PRIME GLOBAL ENTERPRISES

Nonmagnetic hard alloy and preparing method thereof

The present invention discloses a non-magnetic hard alloy and its preparation method. Said non-magnetic hard-alloy used wolfram carbide (WC) as main component, and is formed by adding Ni, Cr and Mo and its prparation method includes: bending material, wet grinding, filtering mixed slurry, drying and seiving, forming, vacuum sintering and checking. As compared with existent technology said invented product has the advantages of high hardness, good abrasive resistance, small friction coefficience, good polishing property, high compression strength and good rigidity, etc.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

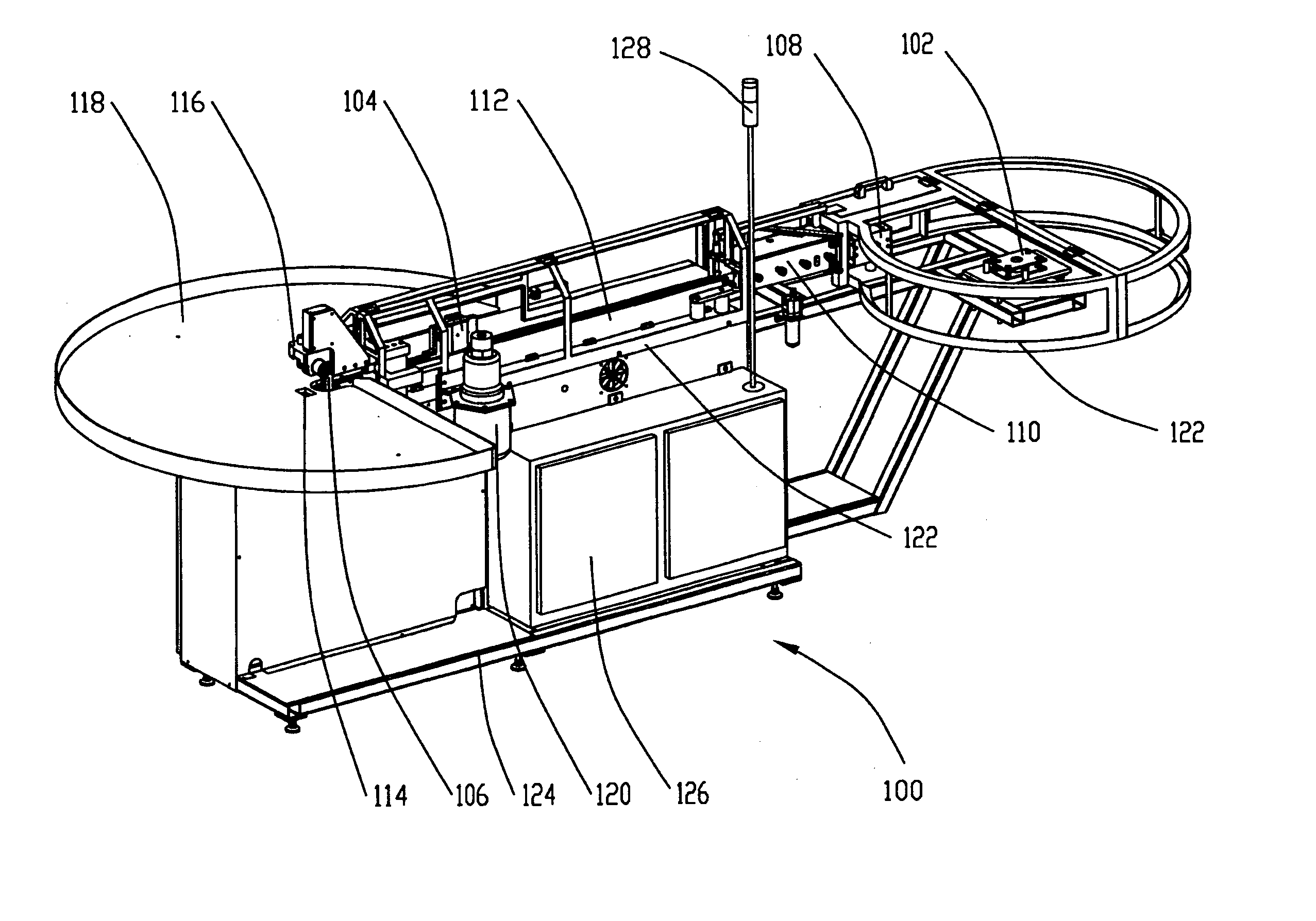

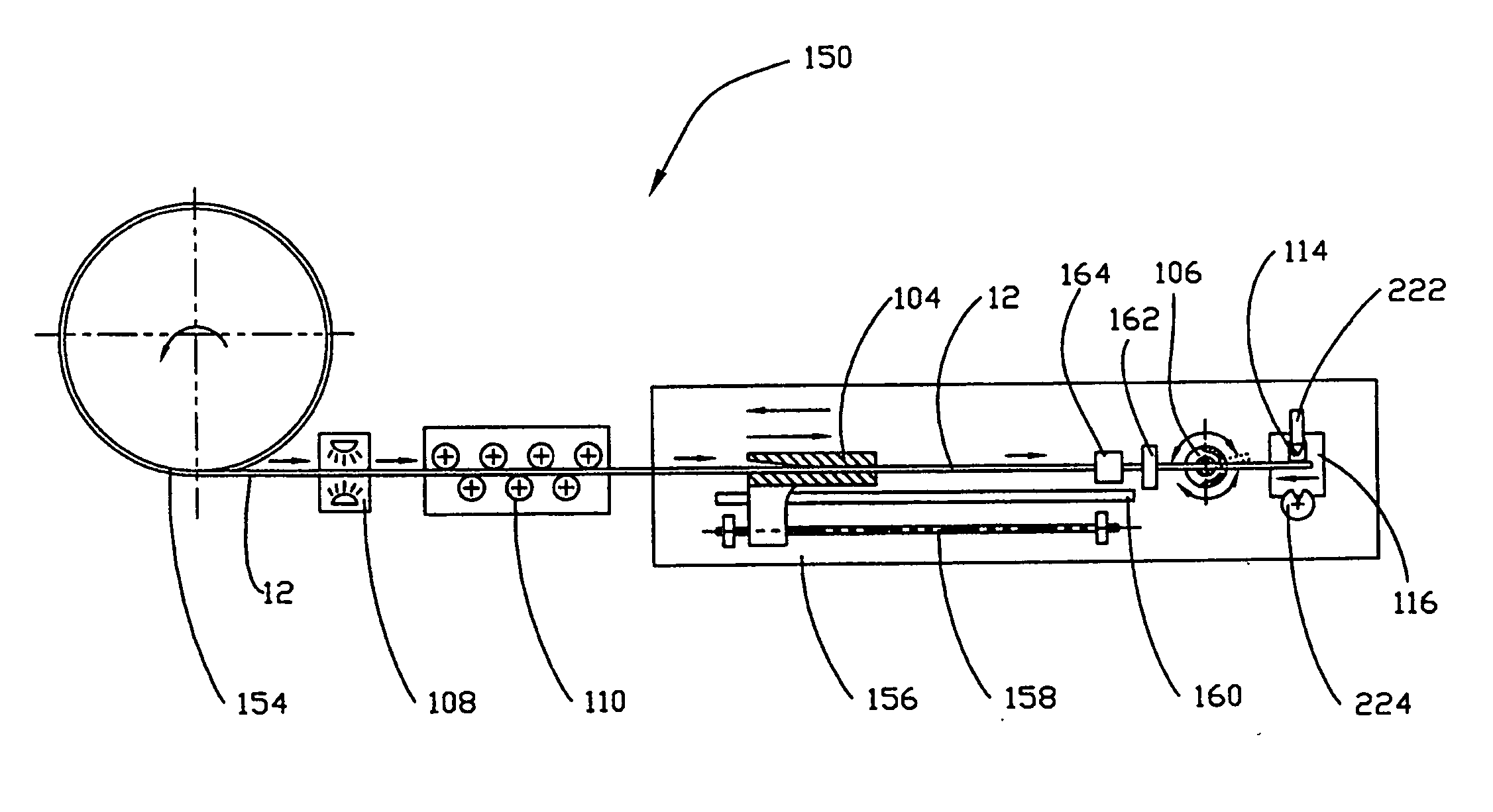

System and method for bending strip material to create cutting dies

The present invention is a bending machine for bending material such as steel to form cutting dies for products such as cloth, leather or the like. Coiled material is fed through a material washer, straightener and printer by a material feeder to a bending head. If required the material is forwarded through the bending head to a heating unit and retracted to the bending unit to aid in bending. A nicking tool is also provided ahead of the bending tool to nick the material. The nicks enable the cutting die to cut notches in the product being cut. A support surface at the output end of the machine supports the material as it is bent into the required form.

Owner:SCOTT WESLEY +3

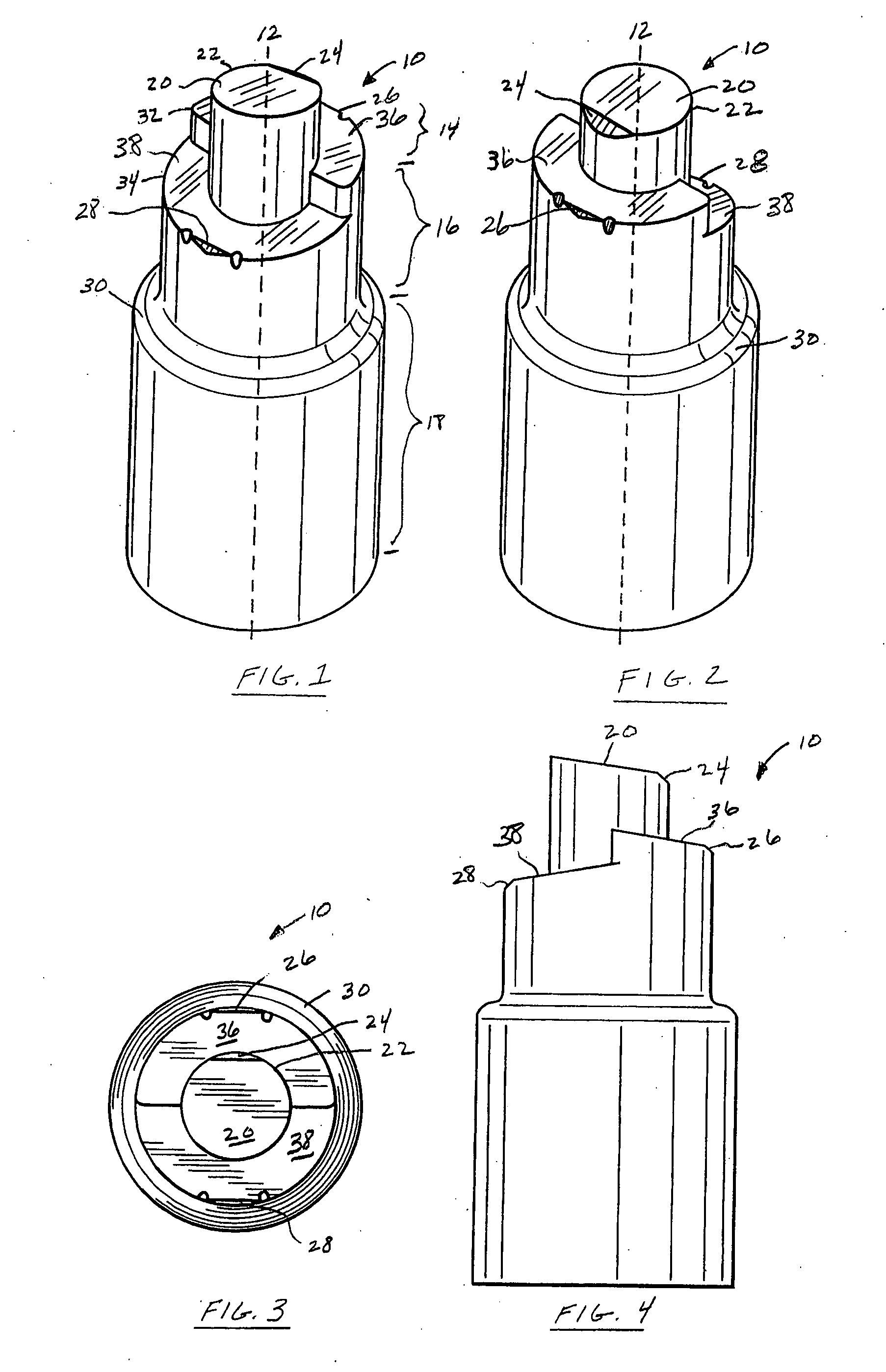

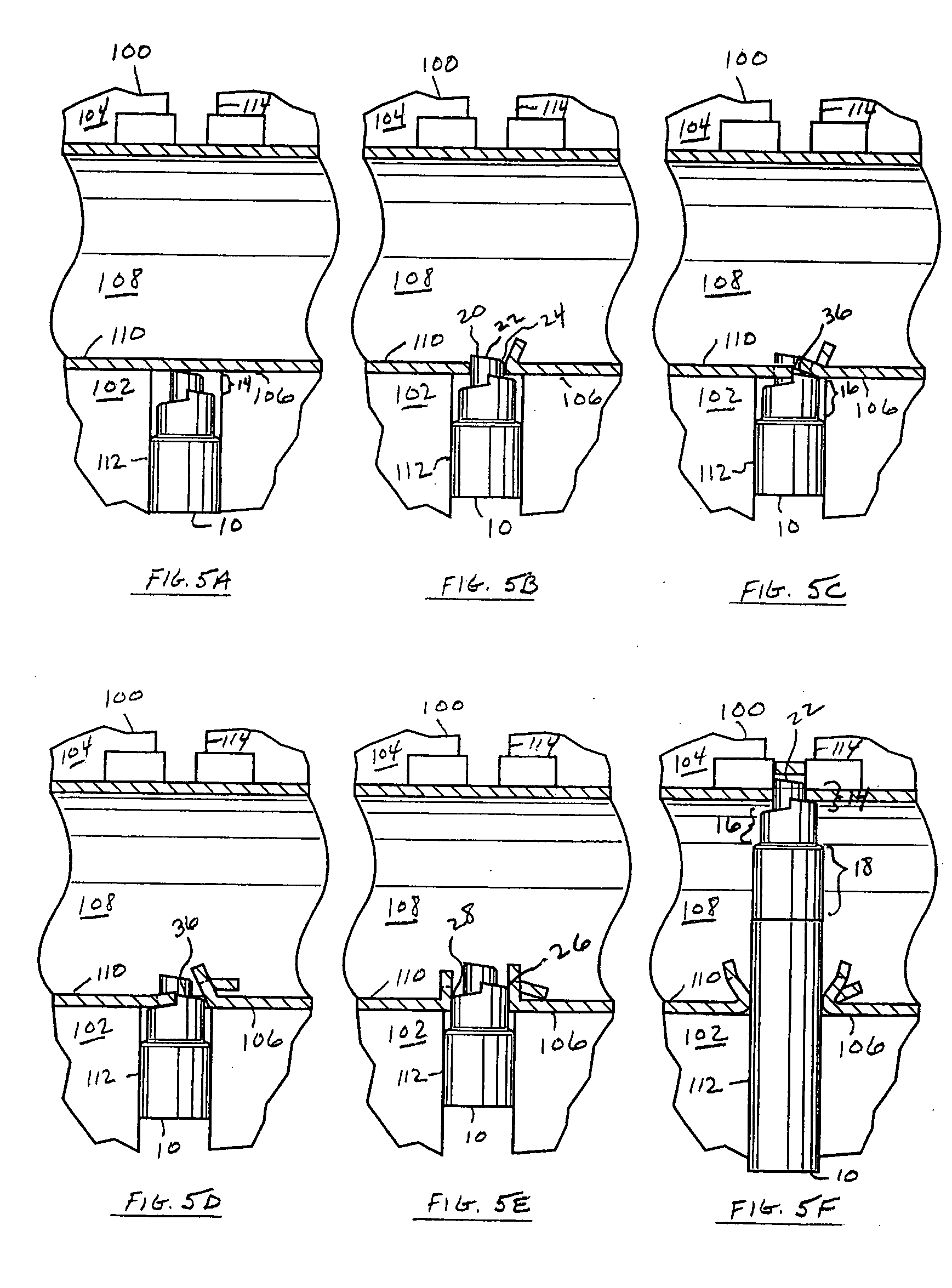

Punch, apparatus and method for forming opposing holes in a hollow part, and a part formed therefrom

Owner:VARI FORM

Rotary draw tube bender

Owner:JPW IND

Automatic heating mechanism

InactiveCN101274349AAchieve uniform temperature effectIncrease productivityCharge manipulationFurnace typesPlate heat exchangerEngineering

The invention relates to an automatic heating device which comprises a roller material feeder and an inductive heating stove, etc., a cascade material feeder is positioned at one end of the automatic heating device, an outlet of the cascade material feeder is opposite to an inlet of the roller material feeder, a control box of material feeding equipments is connected with the cascade material feeder, the roller material feeder and a quick material discharging machine through a cable wire; the outlet of the roller material feeder is opposite to the inlet of the inductive heating stove; a plate-typed heat exchanger set is connected with the inductive heating stove and a power box of the inductive heating stove through a stainless steel water pipe; the outlet of the inductive heating stove is opposite to the inlet of the quick material discharging machine, and a control box of the inductive heating stove is connected with the power box of the inductive heating stove and the plate-typed heat exchanger set through a cable. The automatic heating device substitutes existing manual operating way with the mechanical way, thus having stable material feeding and raised yield; furthermore, multiple levels of bended material detecting devices are adopted so as to detect over-bended materials, thus preventing the stove from being blocked by the bended materials, and avoiding the effects of equipment failure and production influence; the segmented stove is adopted and the temperature of preheated parts is preserved, thus improving temperature consistence.

Owner:FIVE POWER ELECTRICAL TECHKUNSHAN

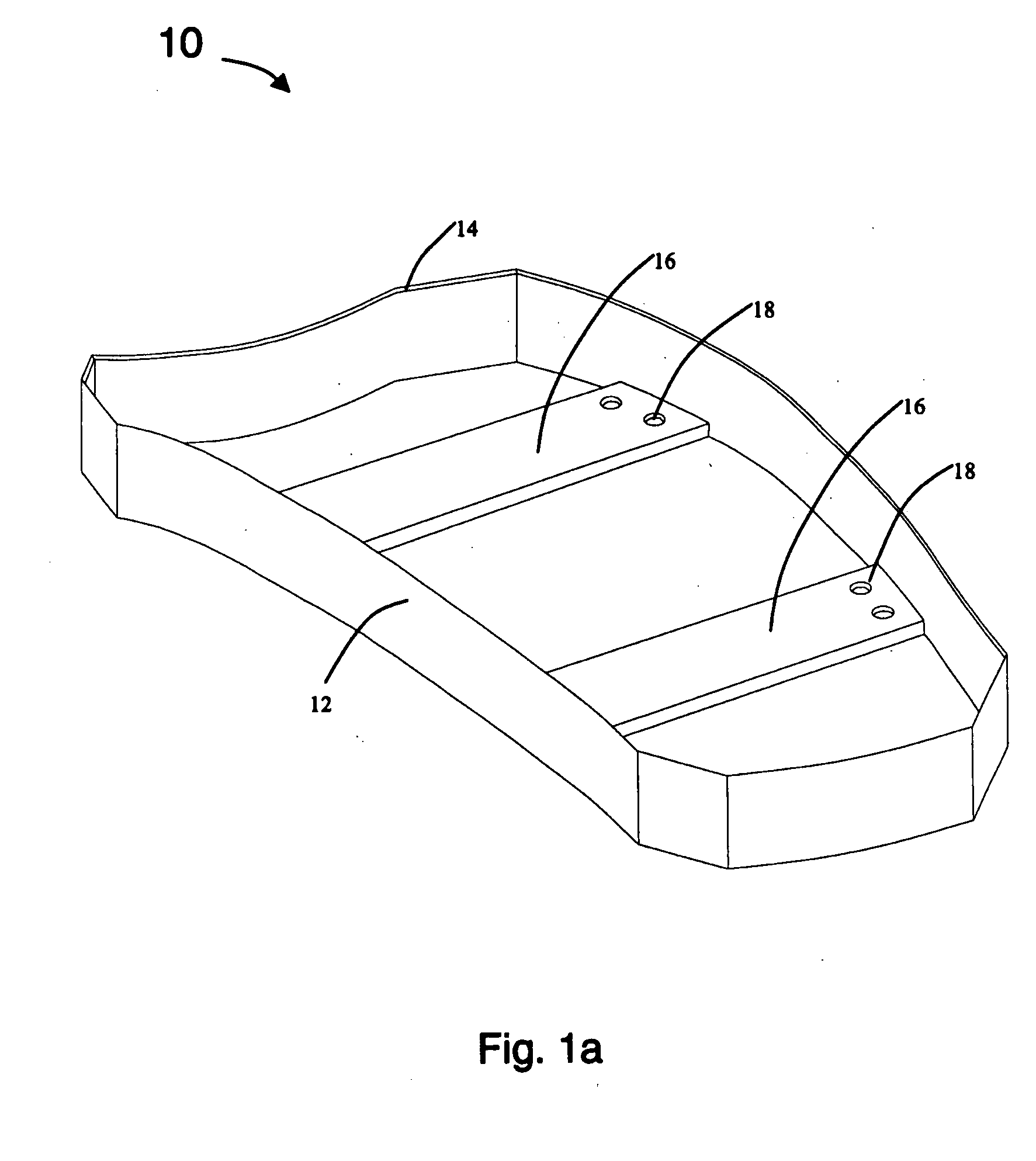

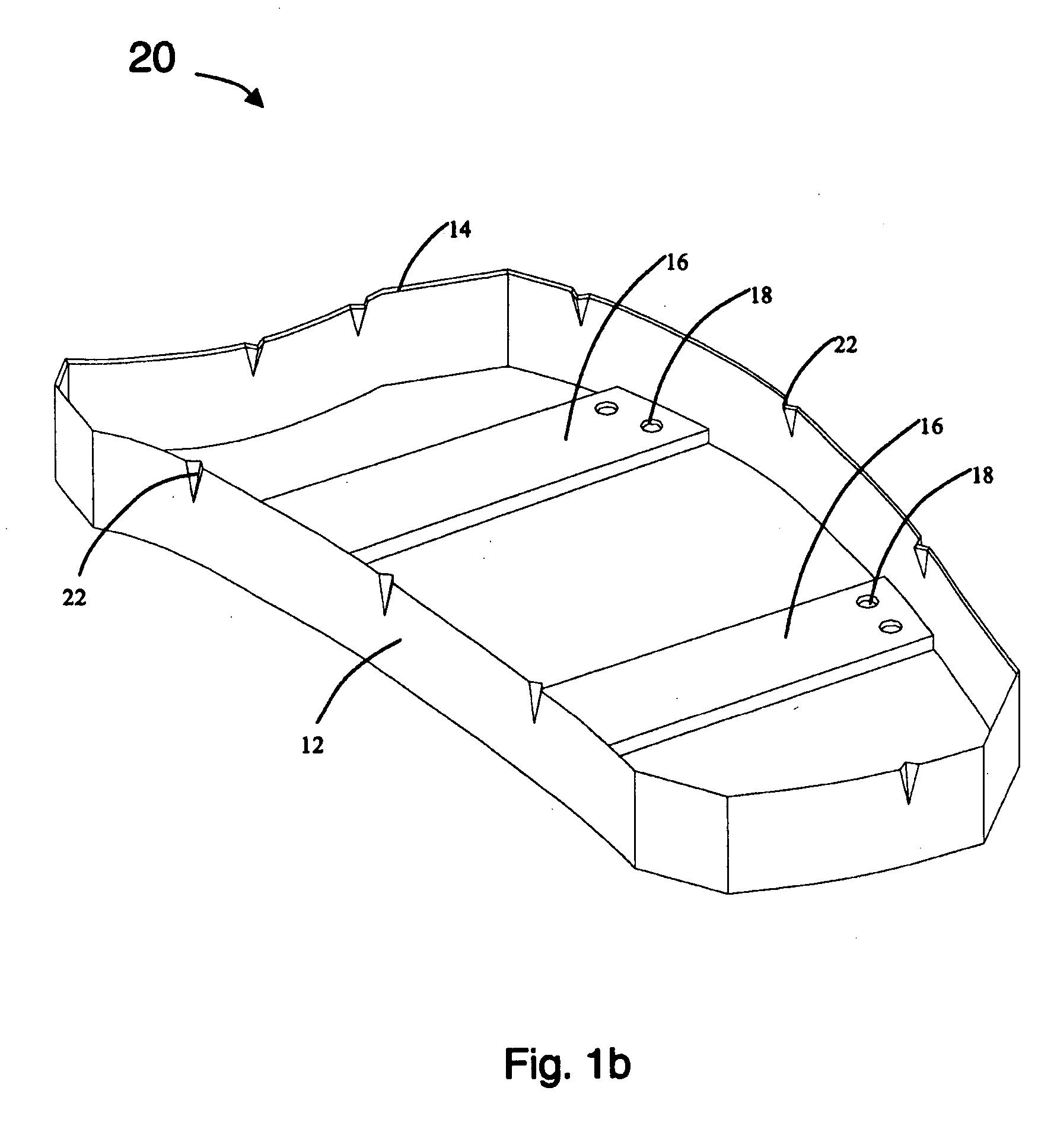

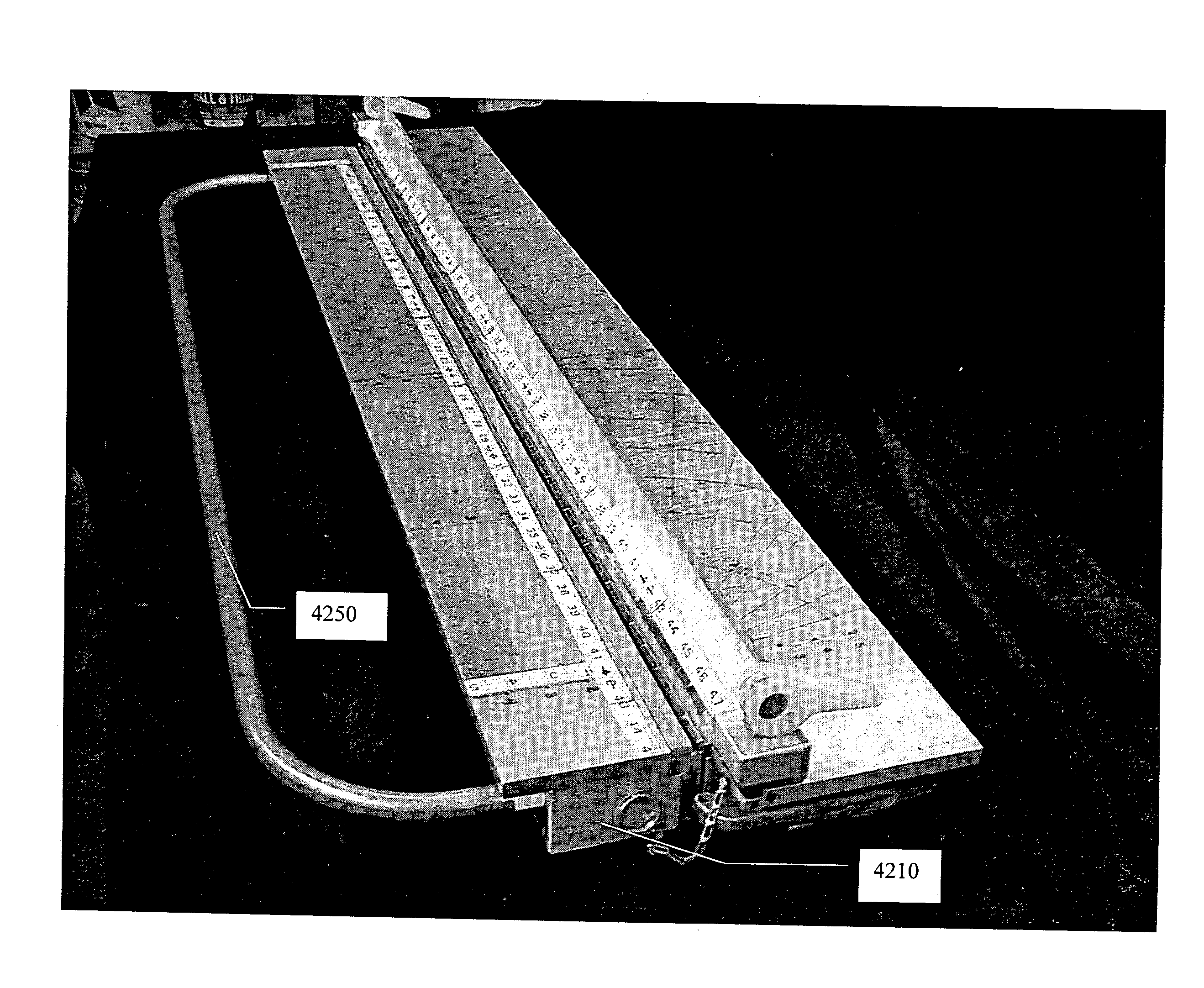

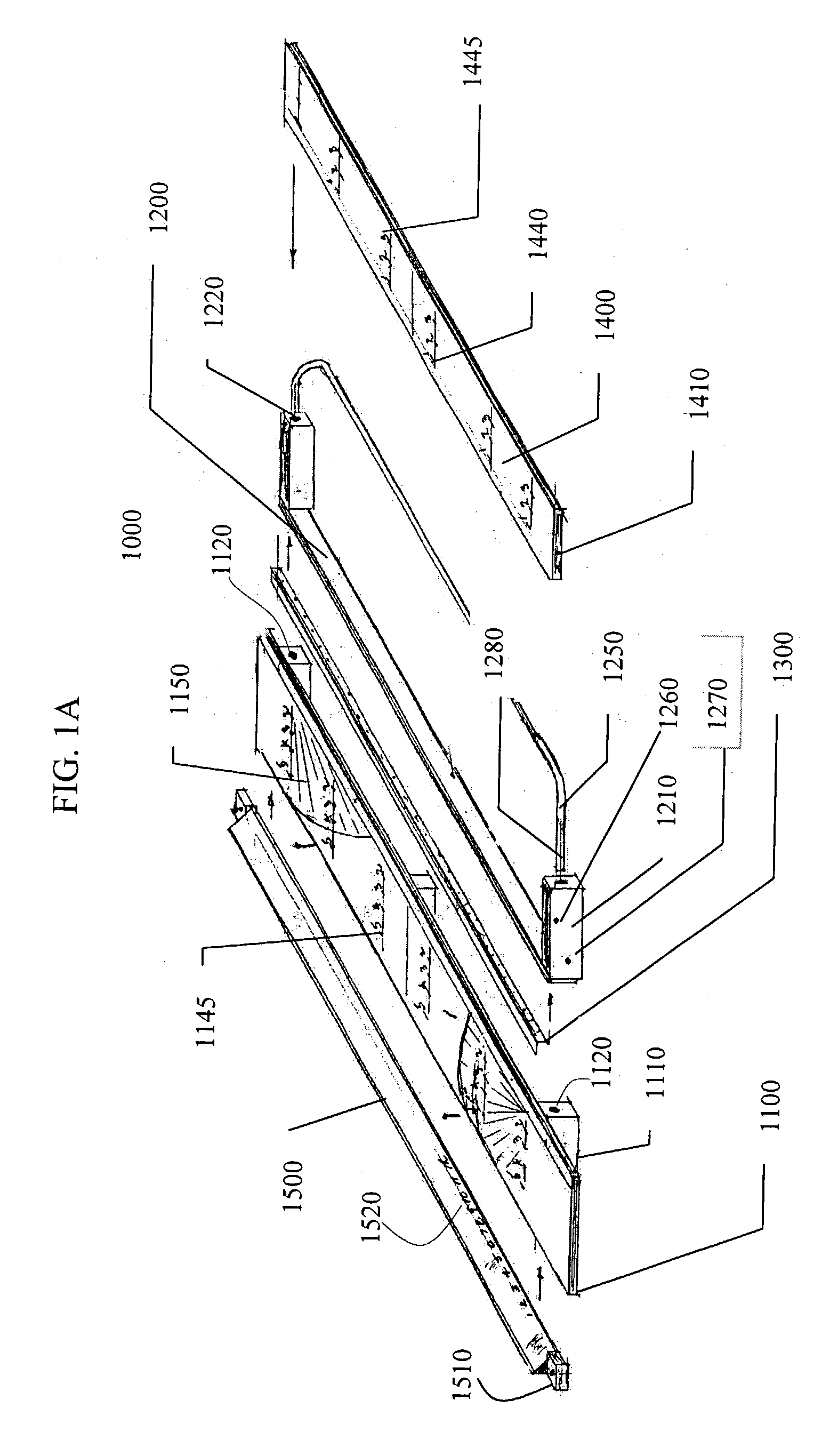

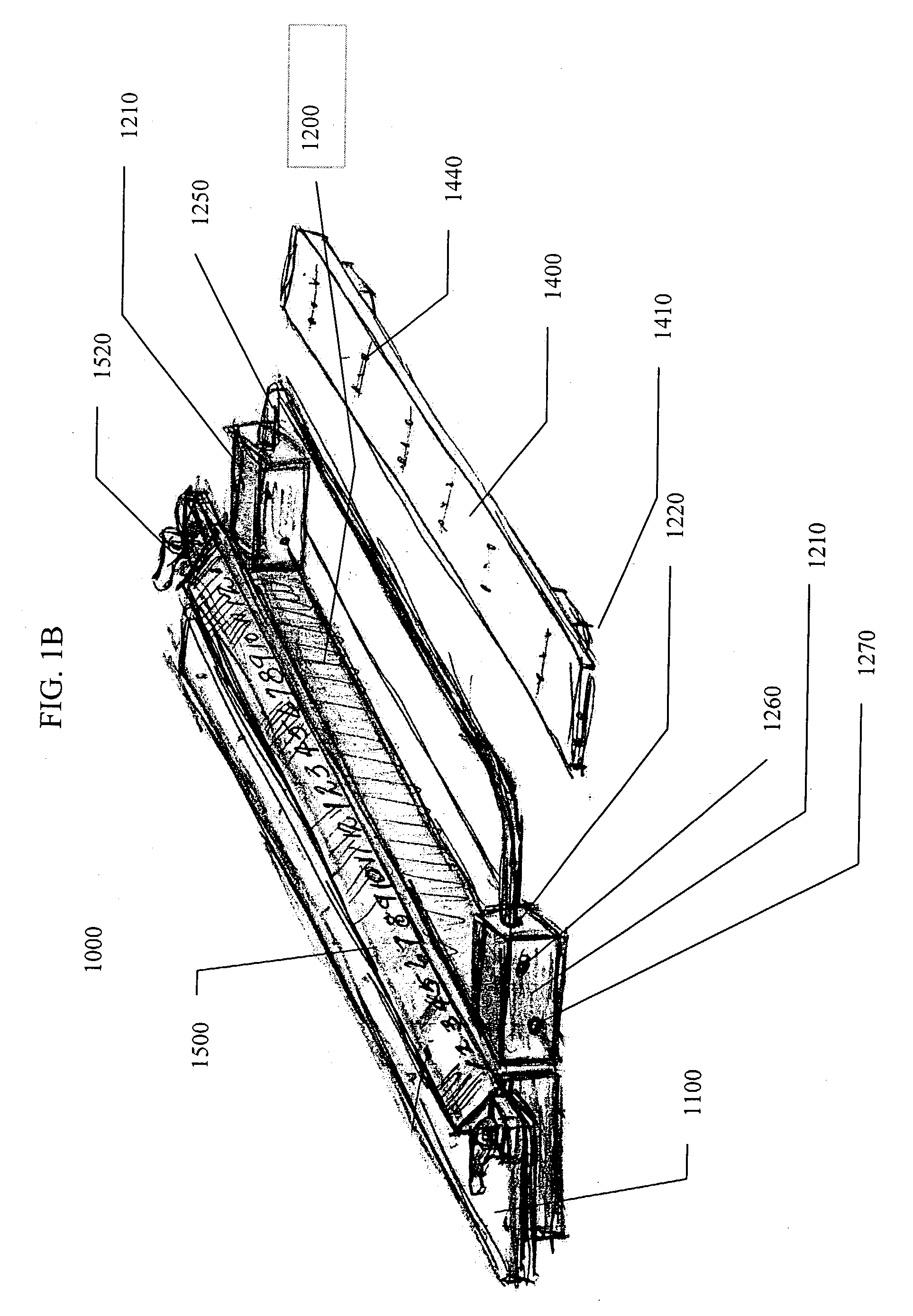

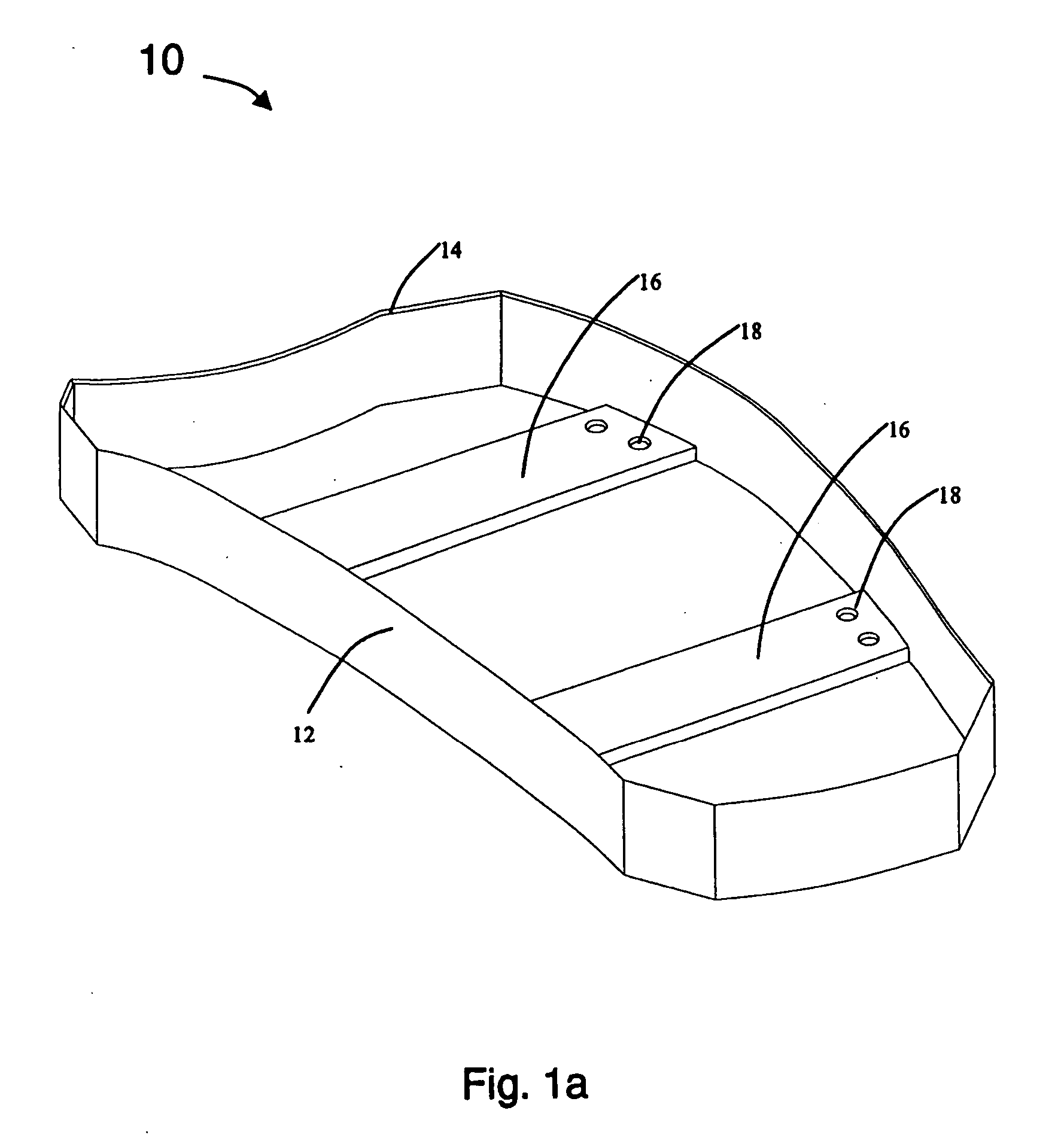

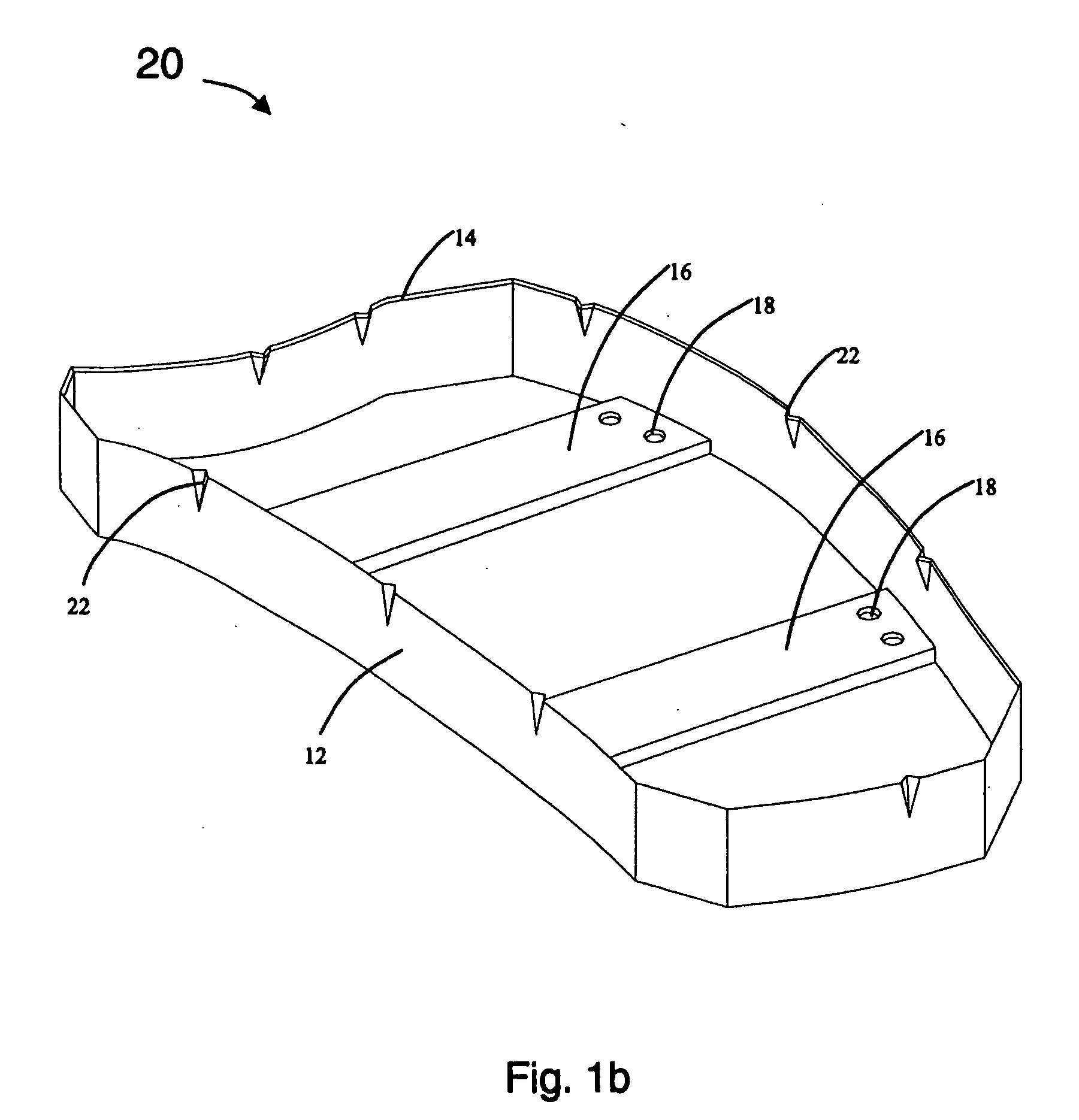

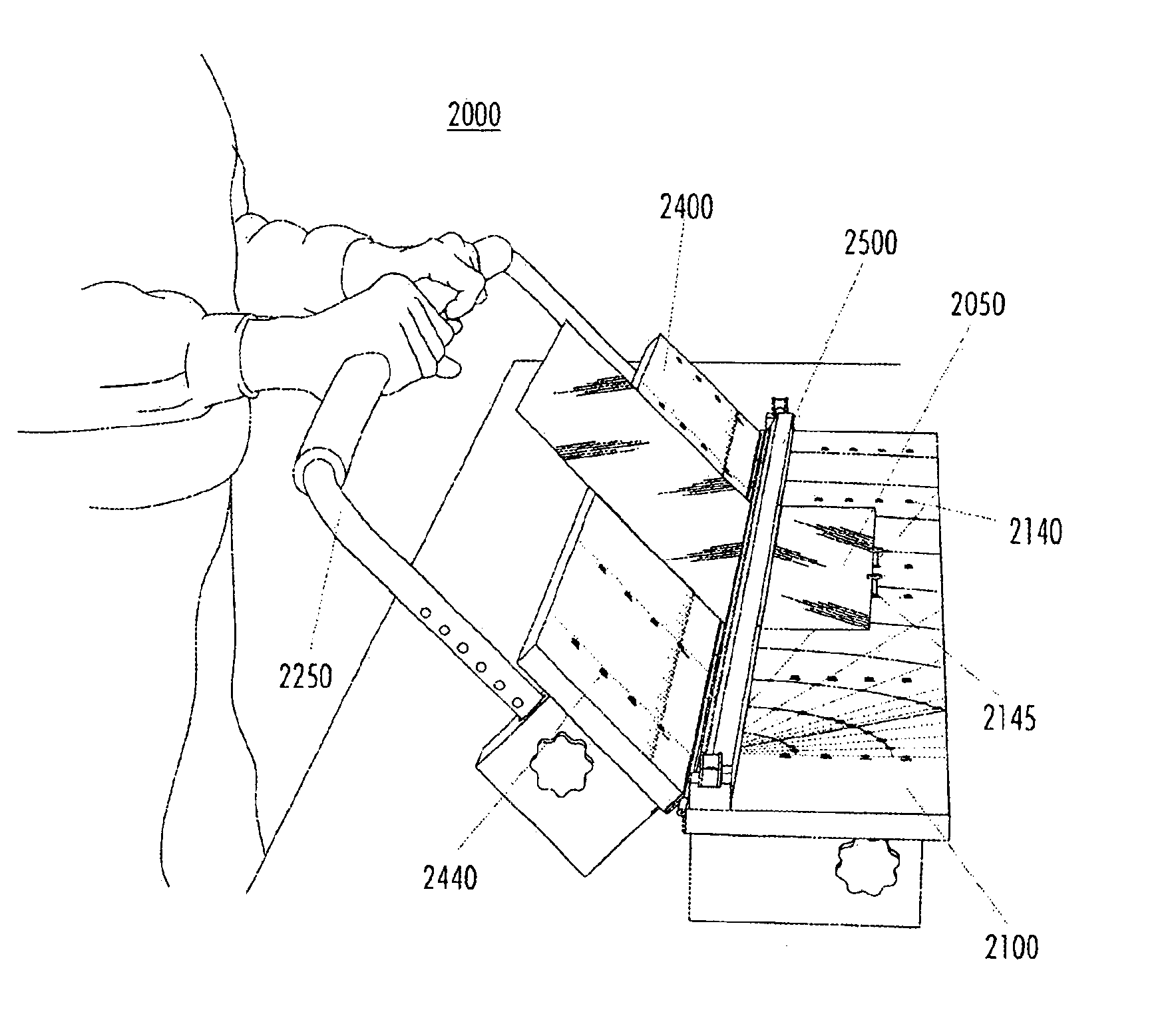

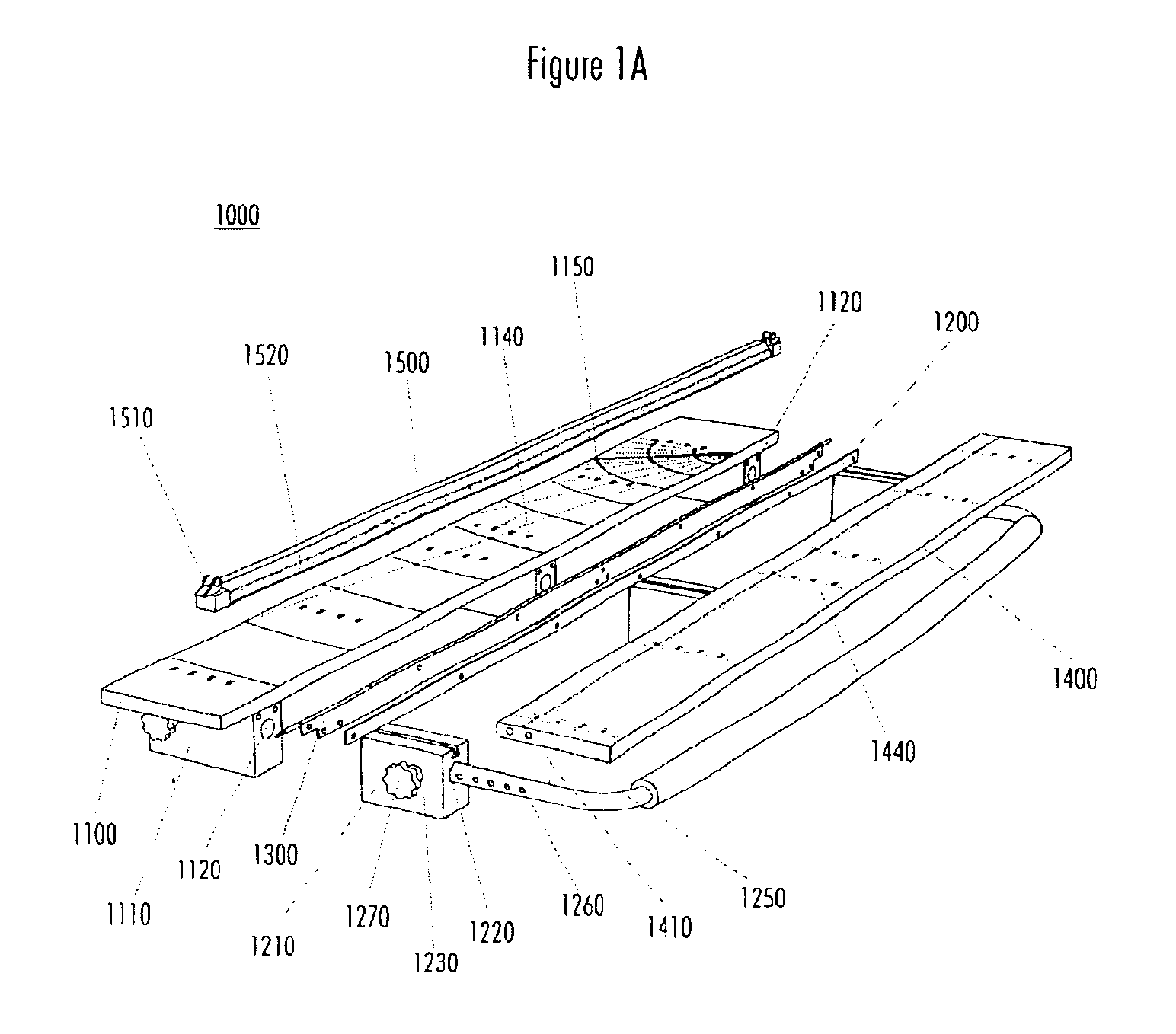

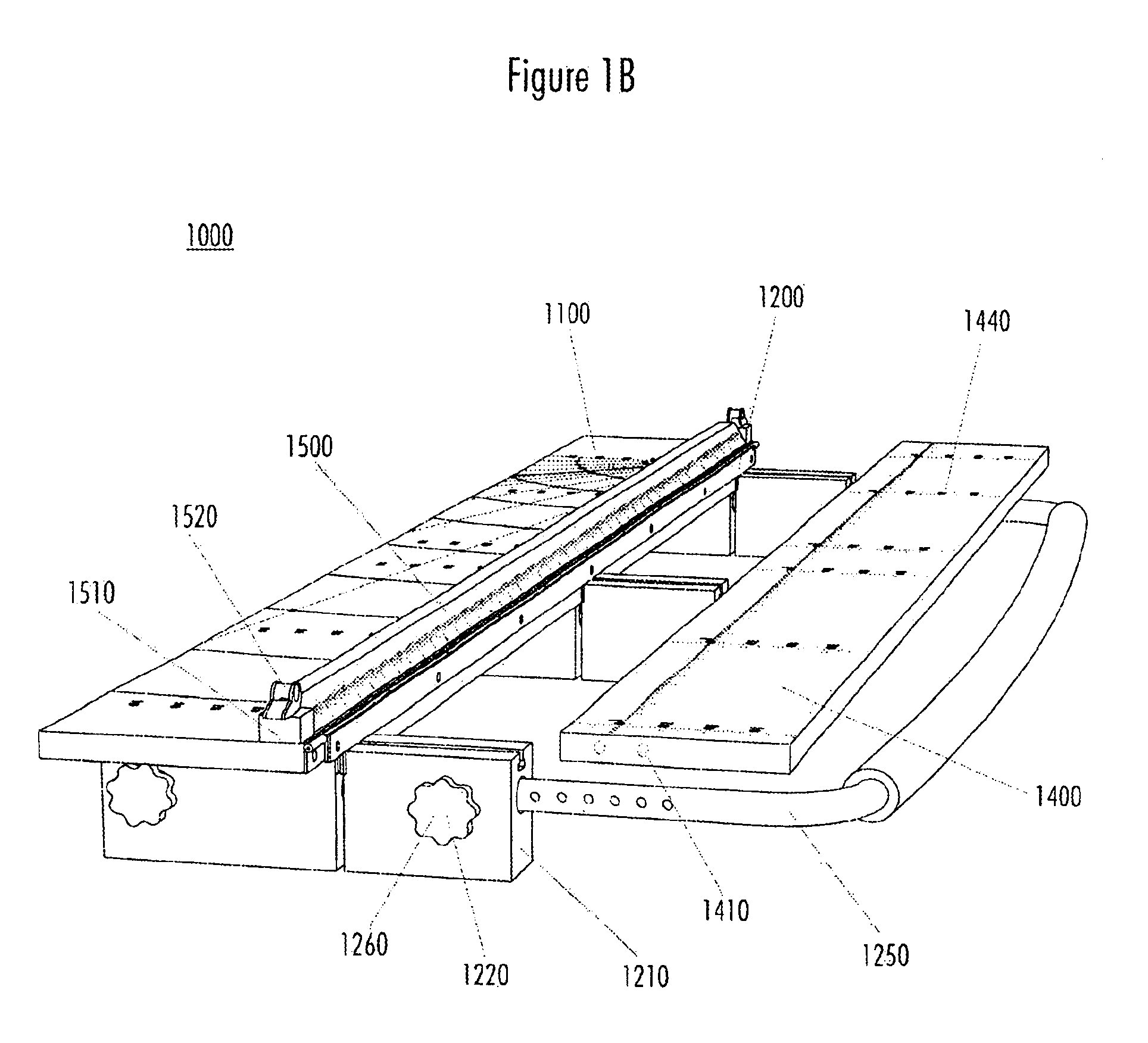

Portable mini-break

A sheet metal bending tool for bending materials, such as flat metal sheets is disclosed. The tool has a restraining base for receiving and cooperatively holding a sheet metal workpiece and the tool has a bending component that is rotatably mounted to the restraining base, the workpiece is held, cooperating with the restraining base component, and the clamp bar for stabilizing the workpiece while the workpiece is held and bent by the rotating action of the bending component. In the preferred embodiment, the workpiece is restrained by a template comprising a pattern of holes drilled, a hole receiving a peg or means of stop, the stops (pegs) constraining the workpiece from movement while being bent act like a jig for measuring and predetermined incumbents. Holes are also drilled in restraining base and in the bending component at spaced intervals along lines that are run parallel to the line defined by the intersection of the bending component and the restraining base. There is a pull back bar that is used for the process of cutting. The Unit can be clamped down also. Rulers are installed on the clamp bar, and the slide table. The apparatus is designed so that two or more may be joined together to form a larger apparatus for the purpose of bending larger workpieces.

Owner:PERRUCCIO DANIEL

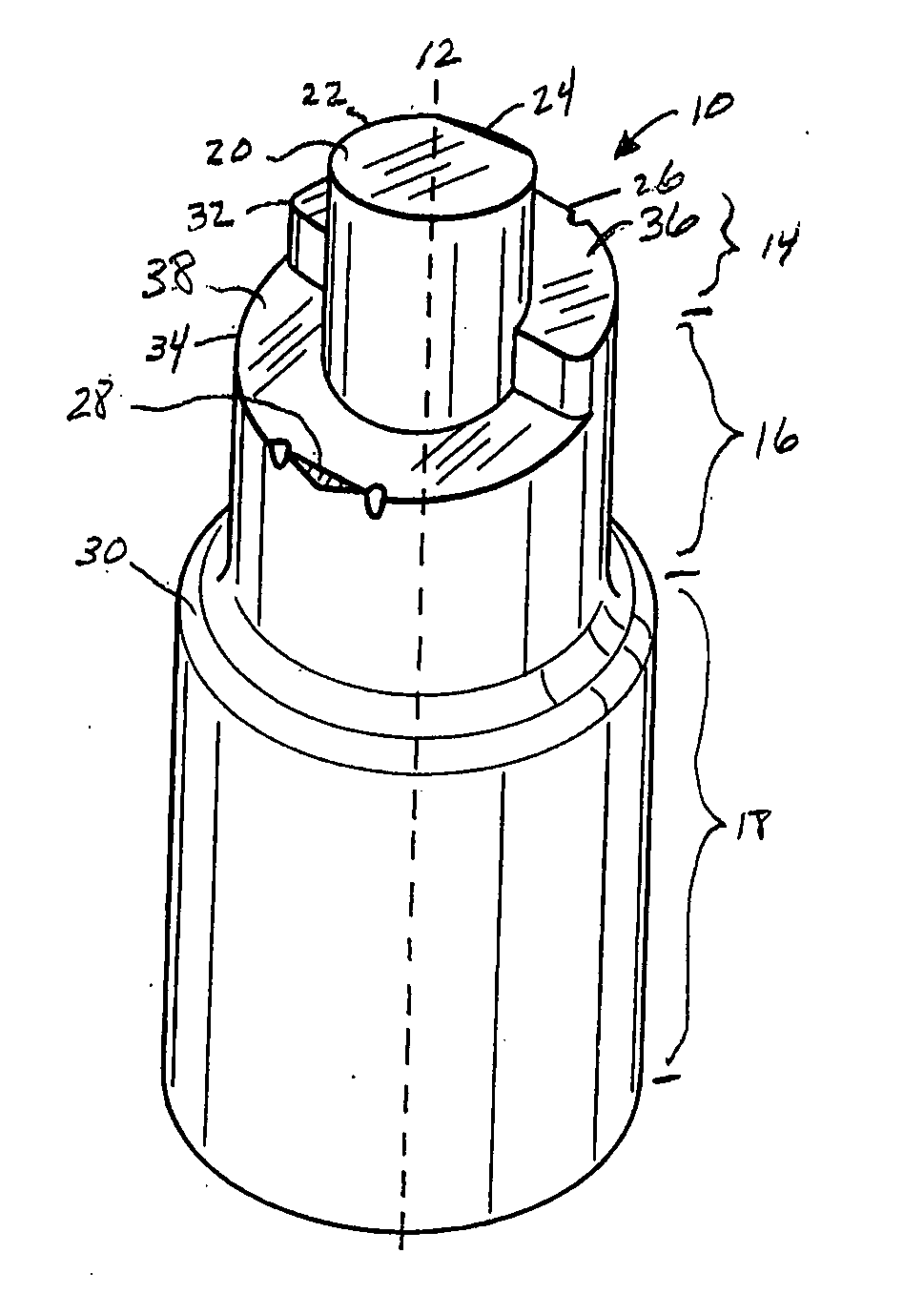

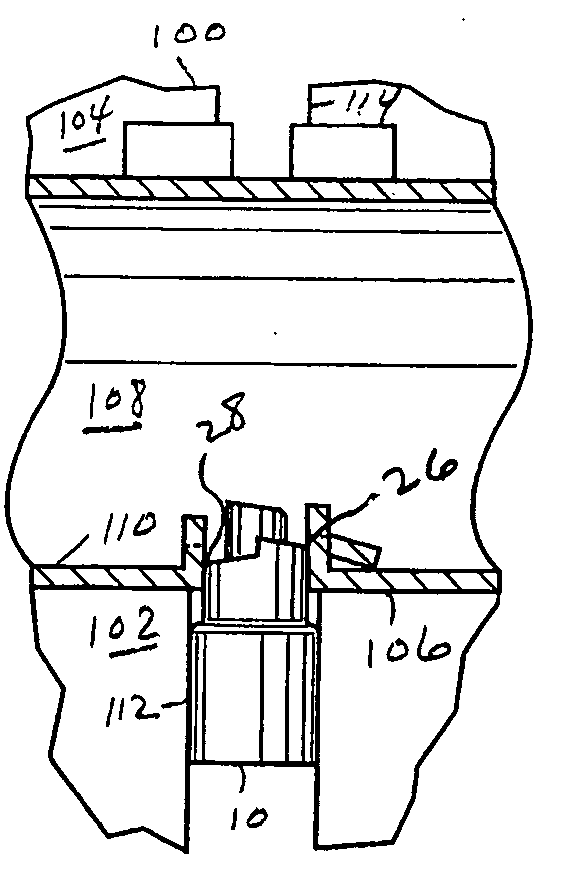

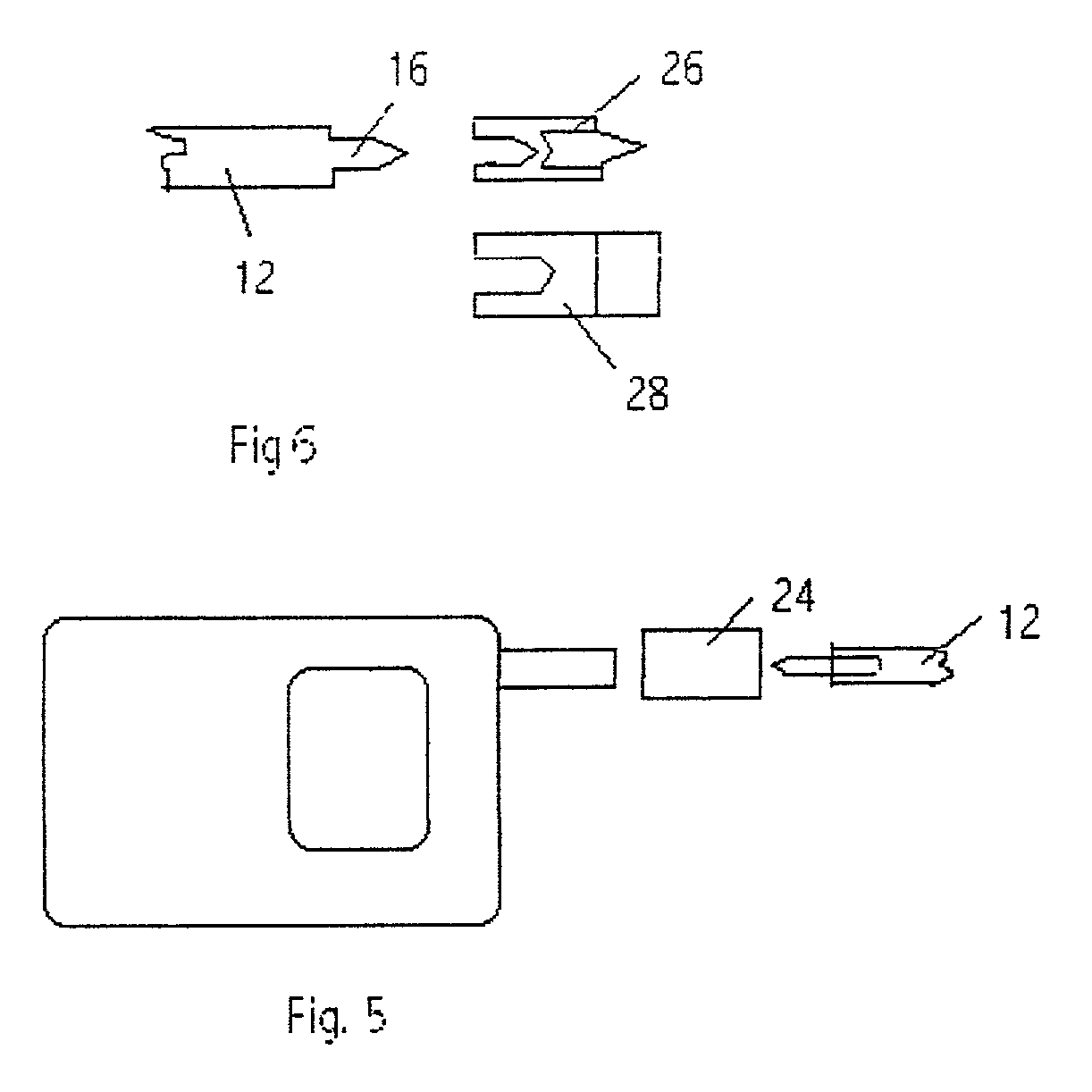

Punch, apparatus and method for forming opposing holes in a hollow part, and a part formed therefrom

A punch, apparatus and method for forming opposing holes in a hollow part, and a part formed therefrom. The punch includes an end portion adapted to pierce an entry hole and bend material around the entry hole to form a retained slug along an inner edge of the entry hole. The punch also includes an enlarging portion adapted to enter the entry hole after the end portion to enlarge the entry hole by bending the slug and additional material towards the interior of the part. The punch has a length greater than a cross-section of the part such that further advancement of the punch through the part punches an exit hole in the part opposite the entry hole.

Owner:VARI FORM

System and method for bending strip material to create cutting dies

The present invention is a bending machine for bending material such as steel to form cutting dies for products such as cloth, leather or the like. Coiled material is fed through a material washer, straightener and printer by a material feeder to a bending head. If required the material is forwarded through the bending head to a heating unit and retracted to the bending unit to aid in bending. A nicking tool is also provided ahead of the bending tool to nick the material. The nicks enable the cutting die to cut notches in the product being cut. A support surface at the output end of the machine supports the material as it is bent into the required form.

Owner:1500999 ONTARIO

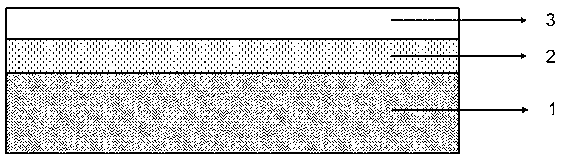

Photo-induced bending conductive actuator and manufacturing method thereof

InactiveCN102990644ARealize integrationMiniaturizationProgramme-controlled manipulatorAldehyde/ketone condensation polymer adhesivesAdhesiveMiniaturization

The invention discloses a photo-induced bending conductive actuator and a manufacturing method thereof. The photo-induced bending conductive actuator comprises a photo-induced bending actuator, a bonding layer and a conductive layer, wherein the photo-induced bending actuator is made of a photo-induced bending polymer material; and the bonding layer is made of an adhesive needing dual-curing. The photo-induced bending conductive actuator simultaneously with the photo-induced bending capacity and the conductive capacity is manufactured, so that the integration and the miniaturization of the photo-induced bending conductive actuator are realized, and the relatively extensive application and the quick development of a photo-induced bending material in the artificial muscle field are accelerated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

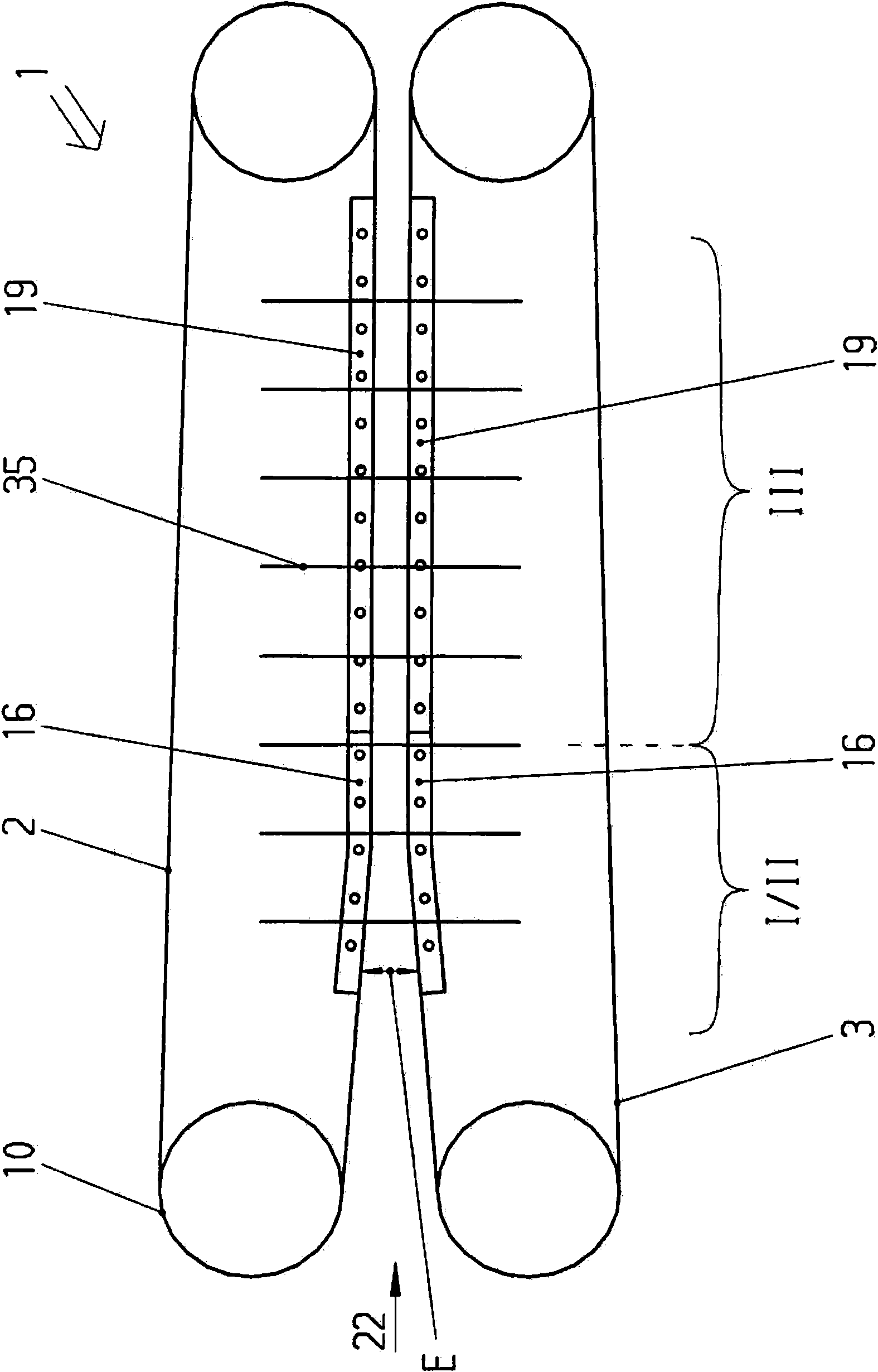

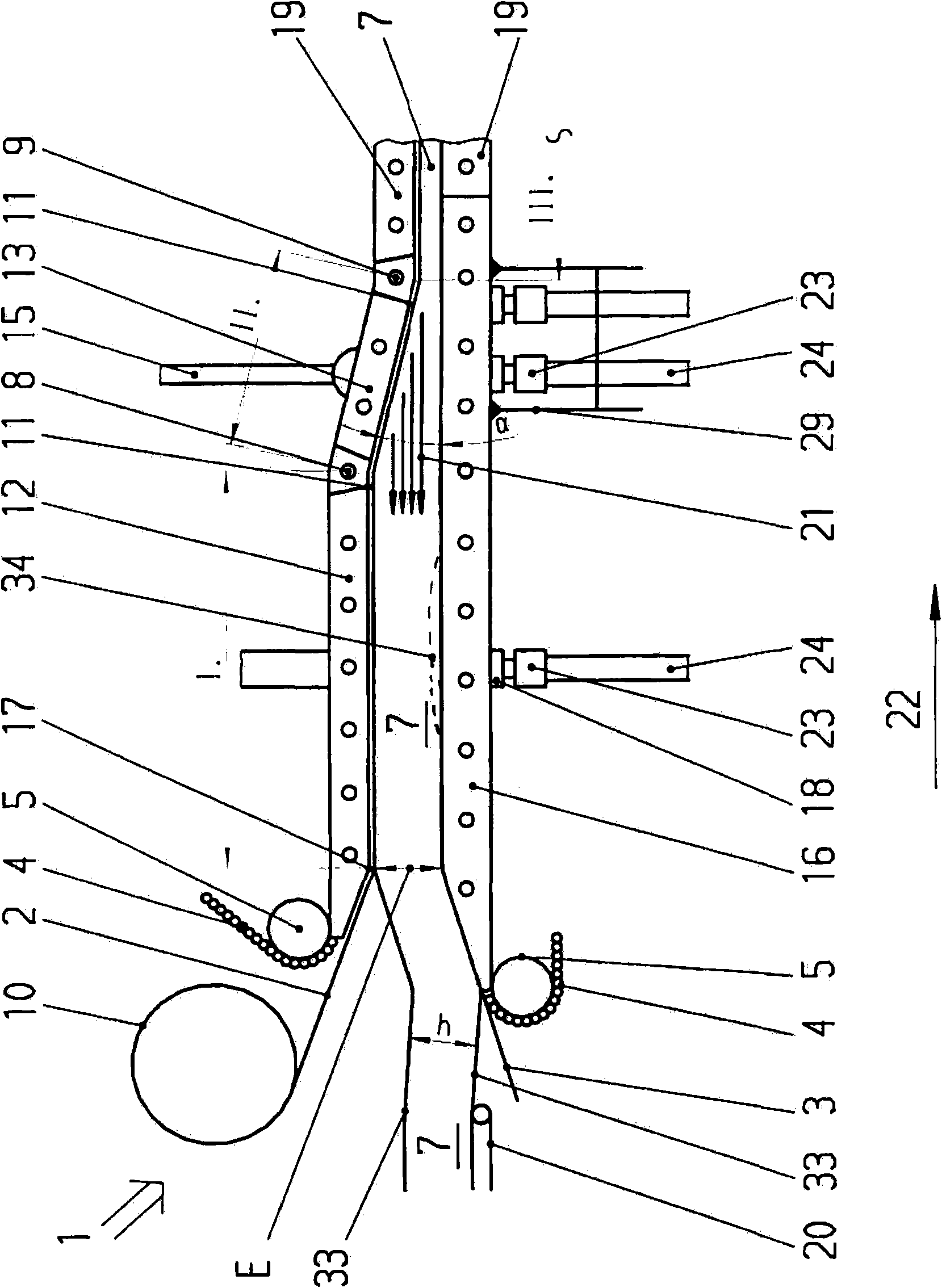

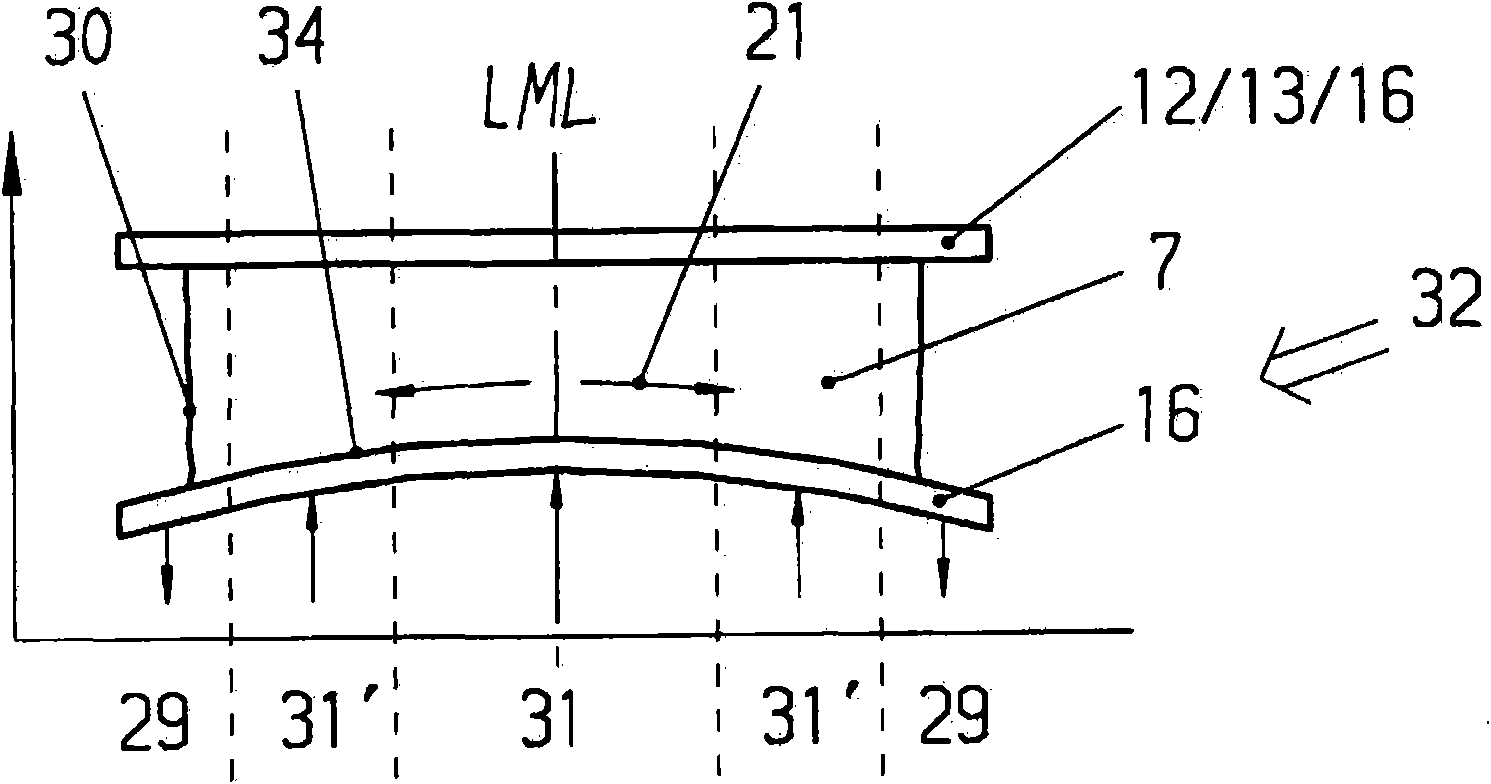

Method for producing composite panels in a continuously operating press and continuously operating press

InactiveCN101856835AAvoid dischargeReduce the risk of fireWood working apparatusDomestic articlesMiddle lineSteel belt

The present invention relates to a method for producing composite panels in a continuously operating press (1). In the continuously operating press (1), the pressing blanks (7) are clamped and / or pressed in an area of material feeding segment before a main pressing area along a production direction (22) through steel strips (2,3) which operate around a bending roller (10) and are supported through a rolling rod (4), wherein in the area of material feeding segment, a material feeding segment heating plate (16) and / or hinging plate (12,13) which are used for regulating the geometric dimension of the material feeding segment clearance (E) along the production direction can adjust the clearance of the material feeding segment heating plate (16) and / or the hinging plates (12,13) and / or can be bended. The settlement solution of the utility model is characterized in that: in passing the areas (I,II) of the material feeding segment, the basically linear material feeding segment heating plate (16) which is perpendicular with the production direction (22) and at least two basically linear hinging plates (12,13) that are perpendicular with the production direction (22) are used on a surface side (33) in at least one segment along the production direction (22); and the bended material feeding segment heating plate (16) which is bended perpendicularly with the production direction (22) at least in the area along a longitudinal middle line (LML) along the direction of the pressing blank (7) from the opposite surface side (33). Additionally, the invention also relates to a continuously operating press.

Owner:DIEFFENBACHER GMBH & CO KG

Portable mini-break

A sheet metal bending tool for bending materials, such as flat metal sheets is disclosed. The tool has a restraining base for receiving and cooperatively holding a sheet metal workpiece and the tool has a bending component that is rotatably mounted to the restraining base, the workpiece is held, cooperating with the restraining base component, and the clamp bar for stabilizing the workpiece while the workpiece is held and bent by the rotating action of the bending component. In the preferred embodiment, the workpiece is restrained by a template comprising a pattern of holes drilled, a hole receiving a peg or means of stop, the stops (pegs) constraining the workpiece from movement while being bent act like a jig for measuring and predetermined incumbents. Holes are also drilled in restraining base and in the bending component at spaced intervals along lines that are run parallel to the line defined by the intersection of the bending component and the restraining base. There is a pull back bar that is used for the process of cutting. The Unit can be clamped down also. Rulers are installed on the clamp bar, and the slide table. The apparatus is designed so that two or more may be joined together to form a larger apparatus for the purpose of bending larger workpieces.

Owner:PERRUCCIO DANIEL

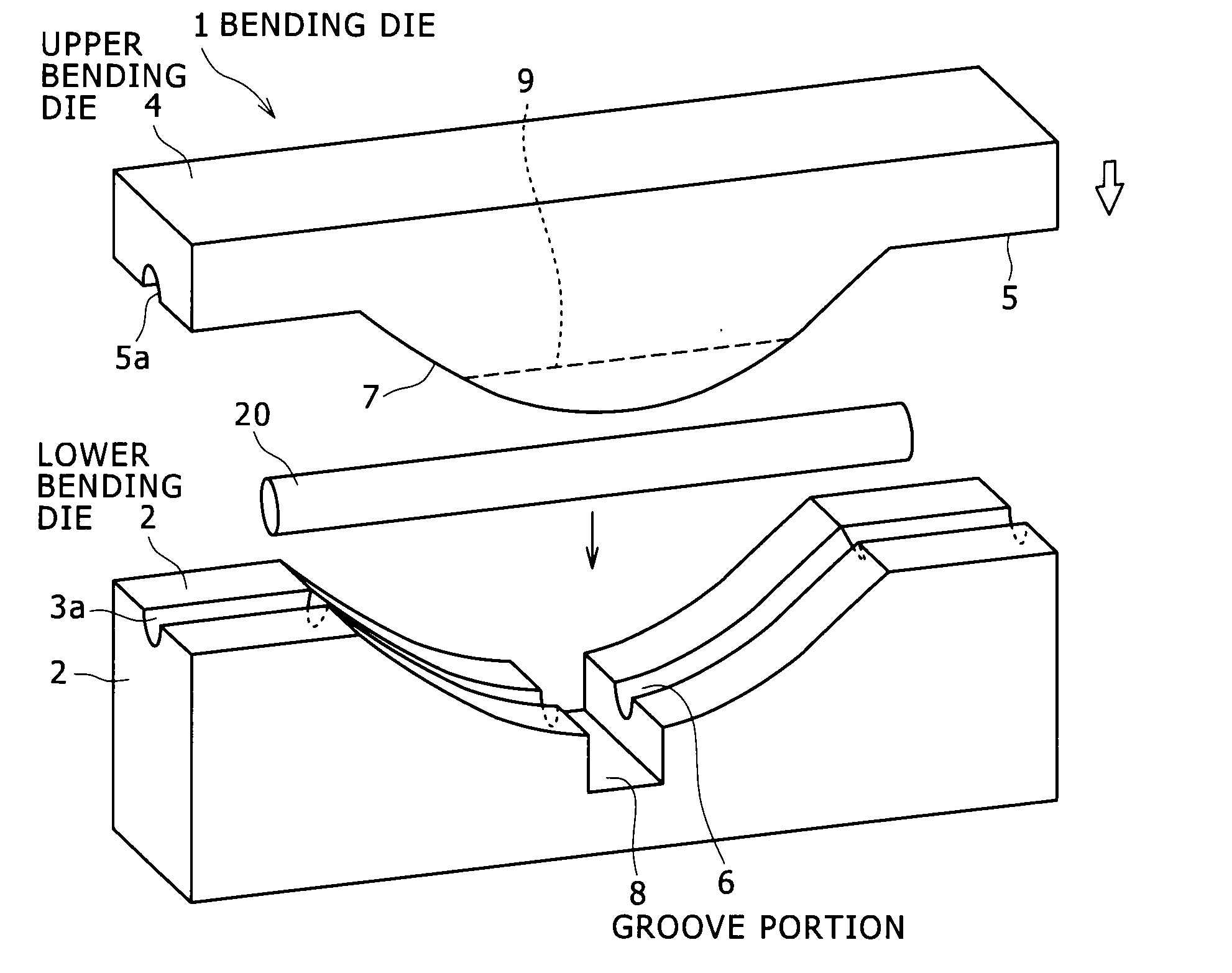

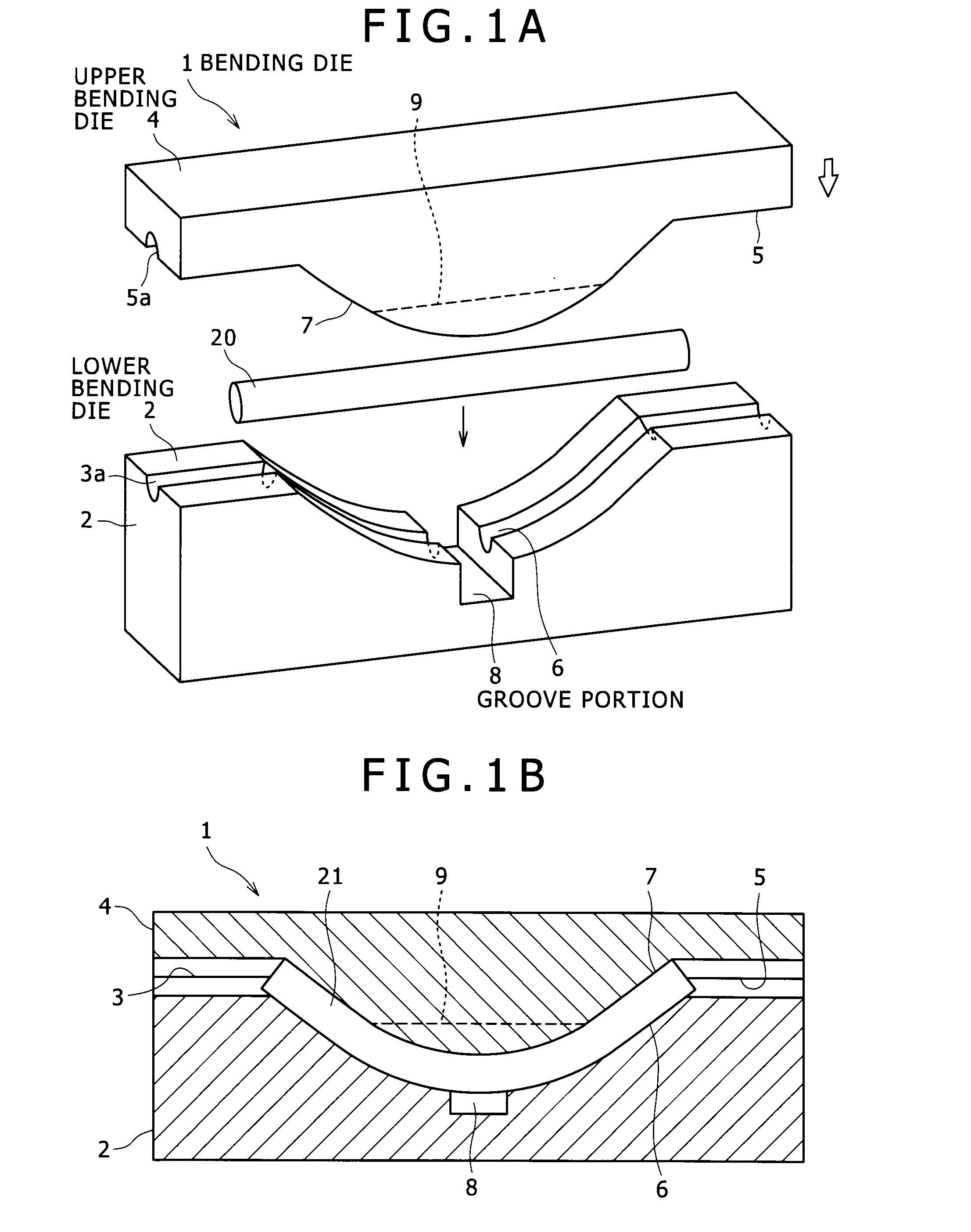

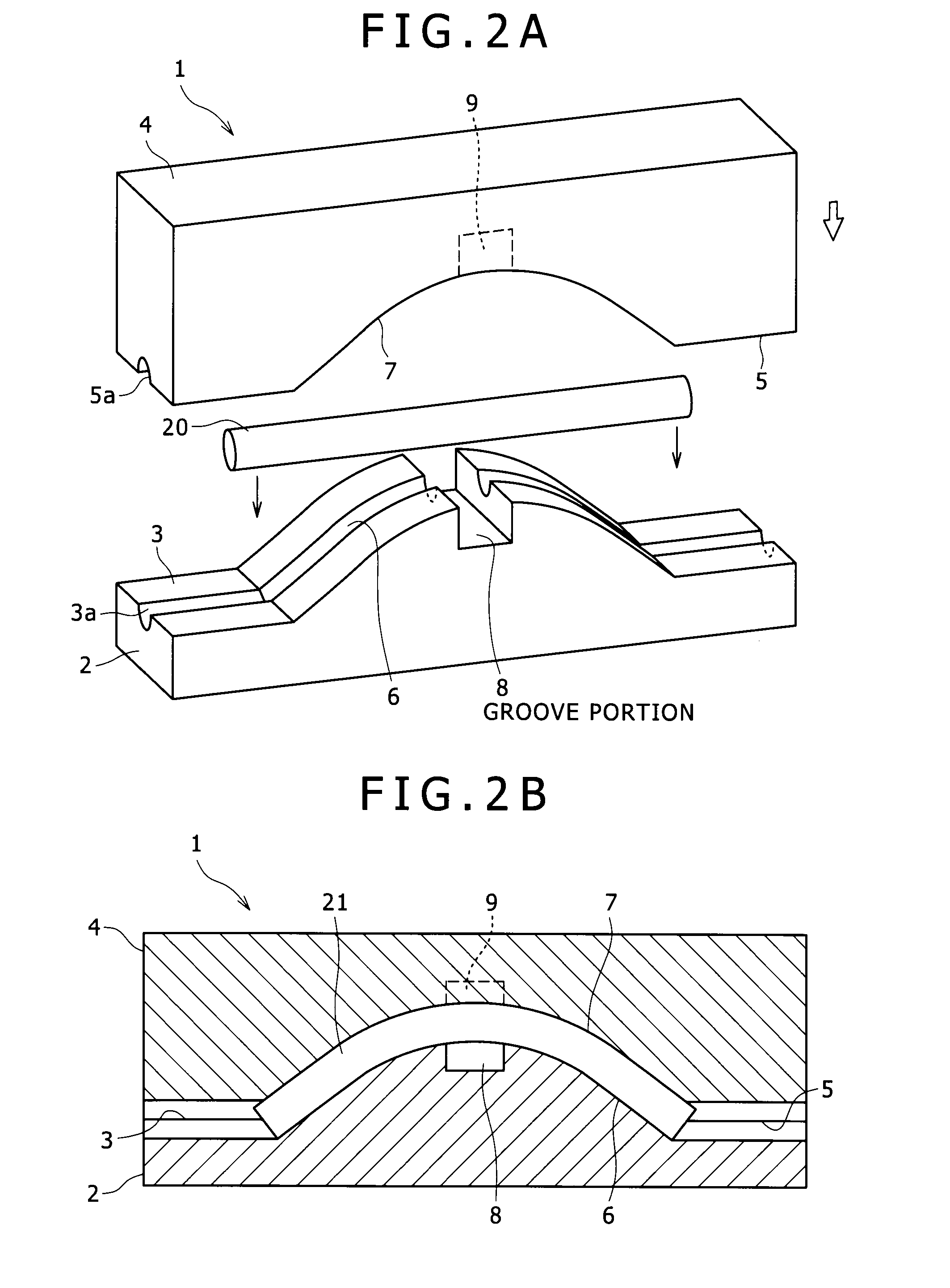

Bending die, and apparatus and method for manufacturing automotive suspension arm using the same

ActiveUS20110302984A1Simple and low-cost structureReduced installation areaForging/hammering/pressing machinesForging press detailsMechanical engineeringRaw material

There are provided a bending die to be used in an apparatus and method for manufacturing an automotive suspension arm to allow the manufacturing apparatus to have a simple and low-cost structure and a reduced installation area and perform automated manufacturing, and the apparatus and method for manufacturing the automotive suspension arm using the bending die. A bending die used in the apparatus for manufacturing the automotive suspension arm to bend a rod-like raw material and produce a bent material includes a lower bending die including a mounting portion for mounting thereon the rod-like raw material and an upper bending die including a pressing portion for vertically pressing the rod-like raw material mounted on the lower bending die. The mounting portion and the pressing portion include a lower die contact portion and an upper die contact portion each formed into a shape along the bent shape of the bent material to come in contact with the bent material. The lower die contact portion includes, in the middle portion thereof, a groove portion formed to have a size which allows a moving means to grip the bent material in non-contact relation with the bent material.

Owner:KOBE STEEL LTD

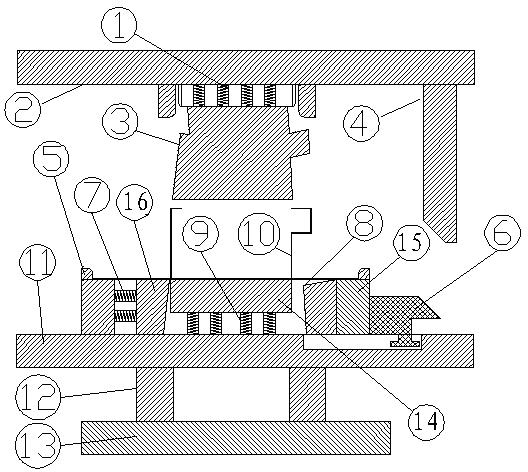

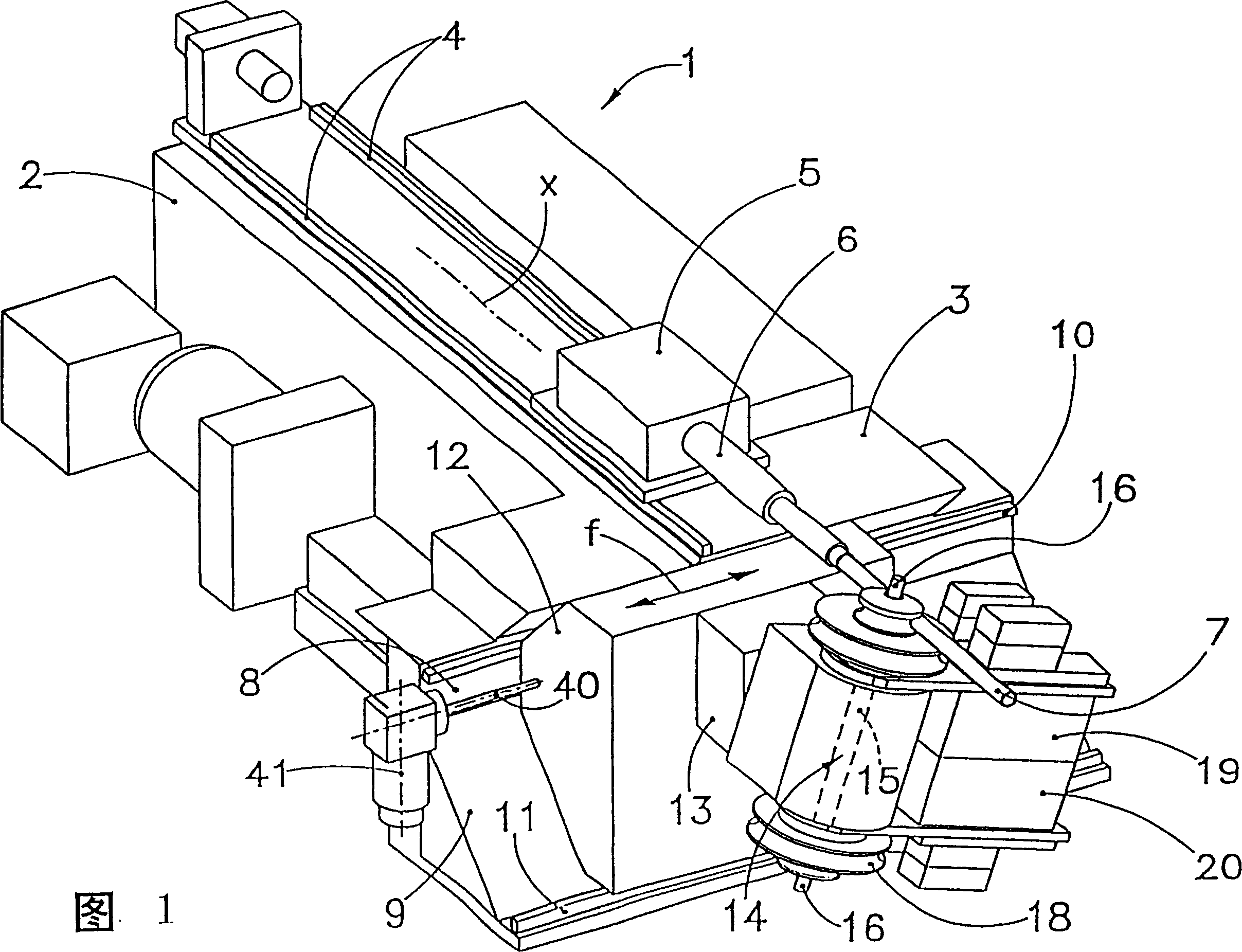

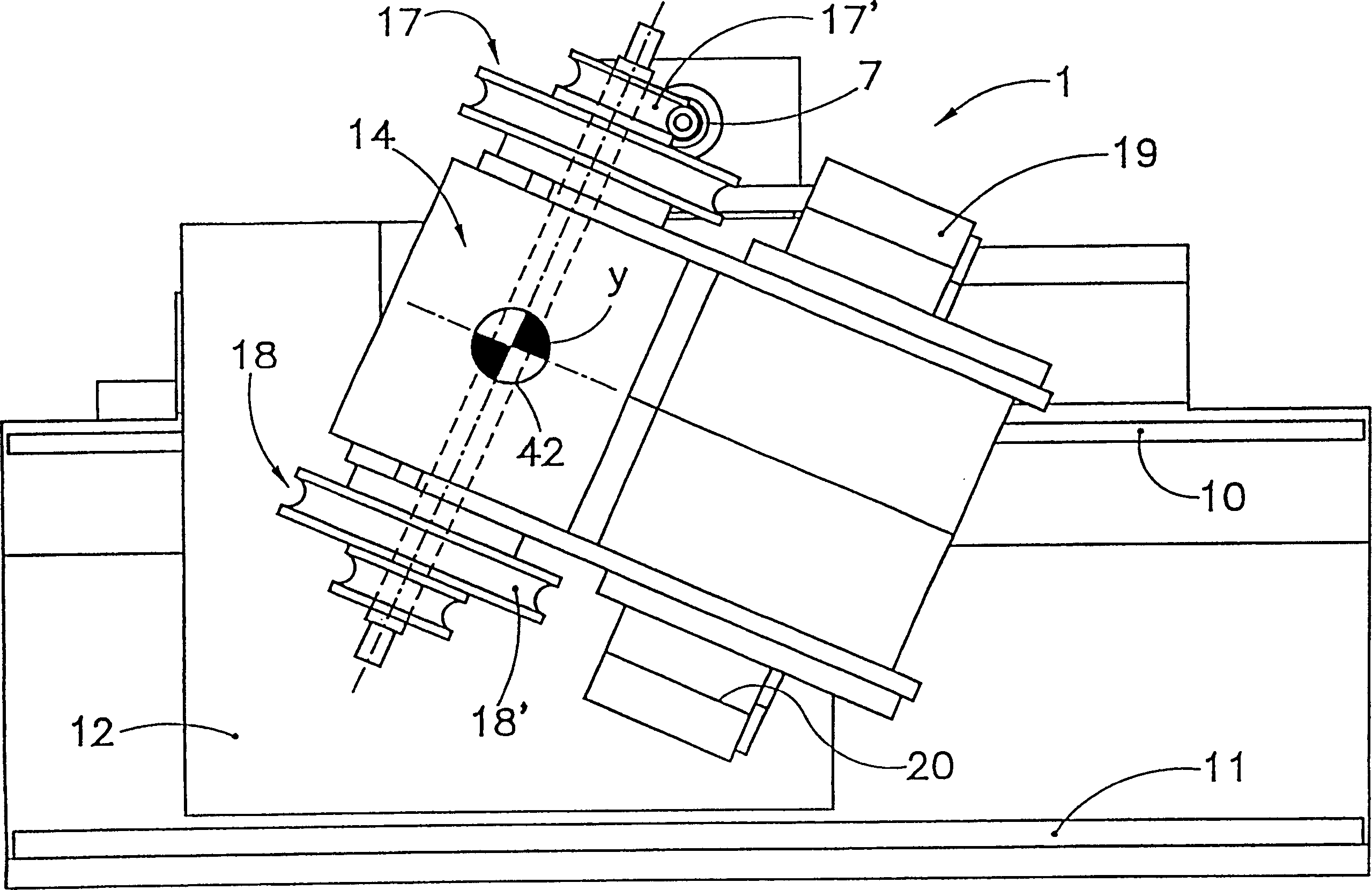

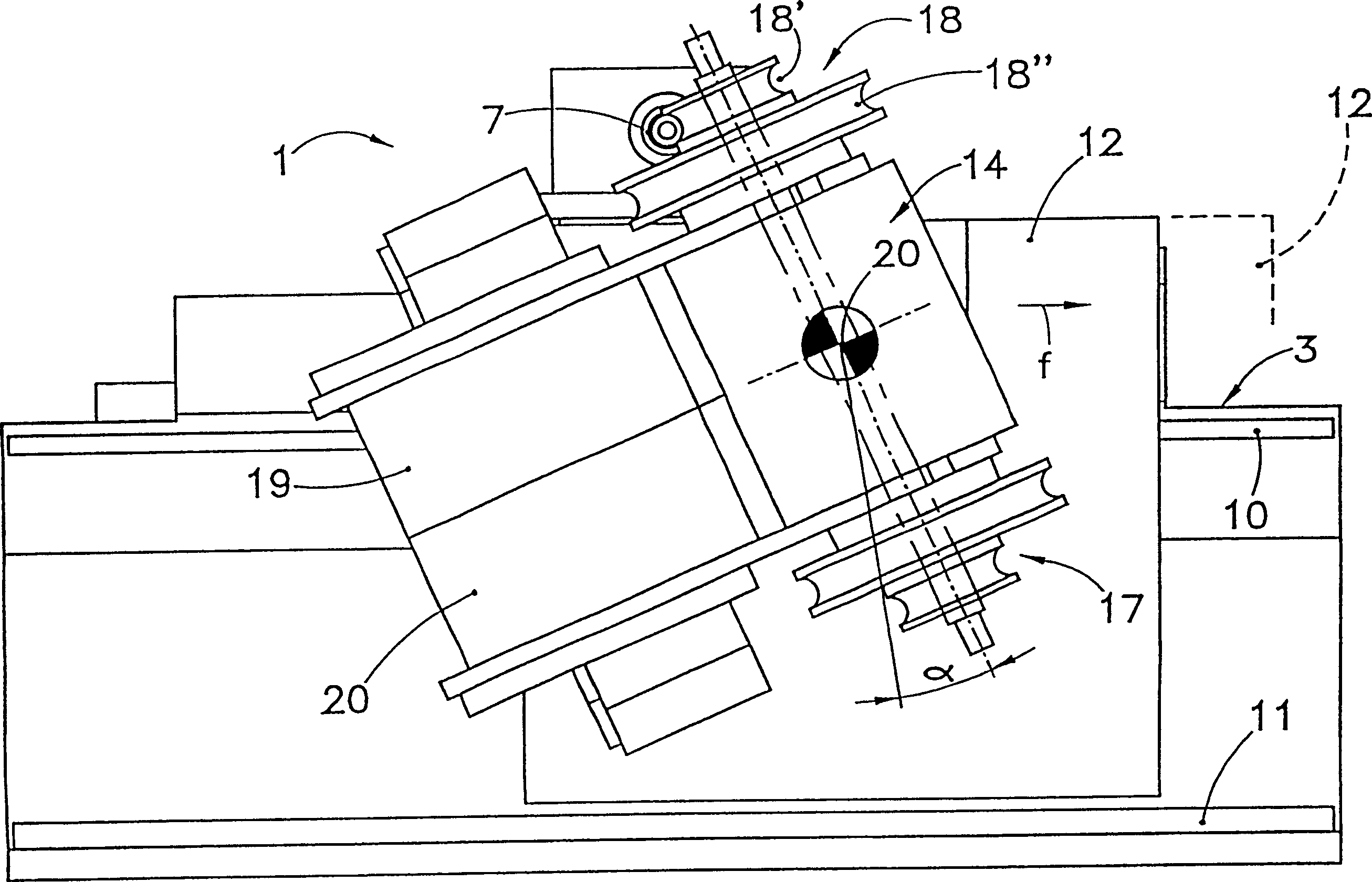

Bender for bending material, such as tube, rod section and/or metal wire rod

InactiveCN1185060CPrecise positioningAccurate removalMetal-working feeding devicesPositioning devicesWire rodEngineering

A bender for tube, rod, shaped wire, or metal wire has a T-shaped machine-tool body with parallel guide bosses the support a driven movable supporter, a parallel guide track mechanism for supporting a movable supporter to feed or rotate the tubular material to position it at a pre-defined position, a bending head equipped to said supporter on bosses, bending module and swinging bending arm. The said bending head is supported by a horizontal axle and can be rotary around the horizontal axle under control.

Owner:BLM

Fixed angle iron waste-material-free punching forming method, mold and production line

The invention discloses a fixed angle iron waste-material-free punching forming method, mold and production line, and belongs to the technical field of fixed angle iron manufacturing equipment, mold and manufacturing method. The forming method provided by the invention is characterized in that direct outsourcing steel belt rollers are mainly used as raw materials; the punching forming is performed by a material conveying mechanism and a punching mechanism. A punching mold is invented on the basis of the method; the front half part of a female template of the mold is a hole punching female mold used for punching holes in raw materials; the back part of the female mold of the mold is a bending female mold used for bending material sheets subjected to the hole punching; a hole punching head is fixed in a position, corresponding to the hole punching female mold, of the punching head fixing plate; a bending punching head is fixed in a position corresponding to the bending female mold; a cutting punching head used for cutting the material sheets is arranged on the punching head fixing plate corresponding to a position between the hole punching female mold and the bending female mold. The invention also provides a punching protection line based on the mold. The method, the mold and the production line provided by the invention have the advantages that the punching bending forming work procedures are simple and convenient; the forming speed is high; the production efficiency is greatly improved; no leftover is left; the production cost is greatly reduced.

Owner:CANGZHOU ORBON ELECTRICAL & MECHANICAL PROD MAKING

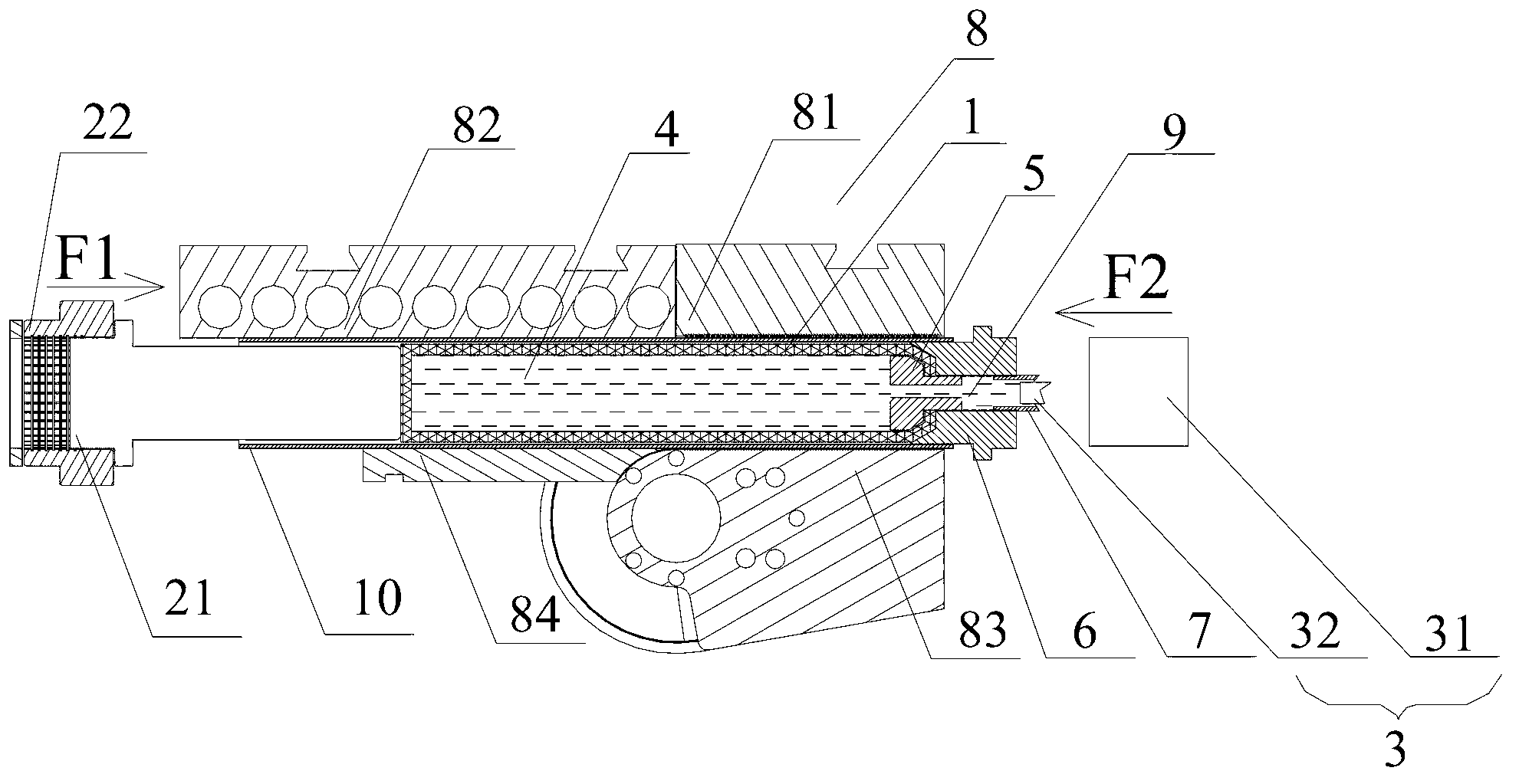

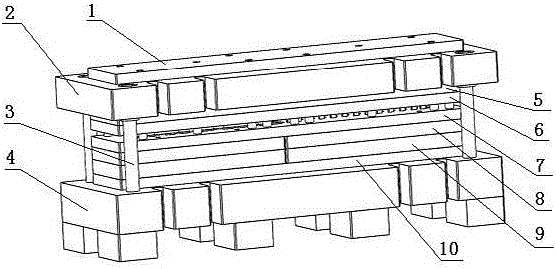

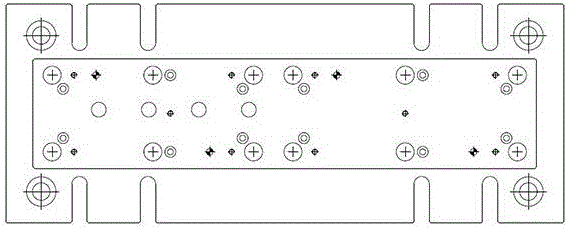

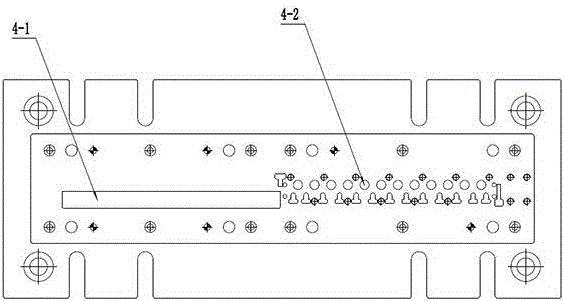

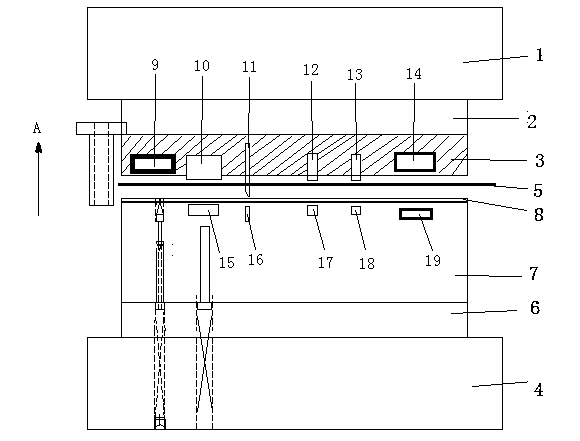

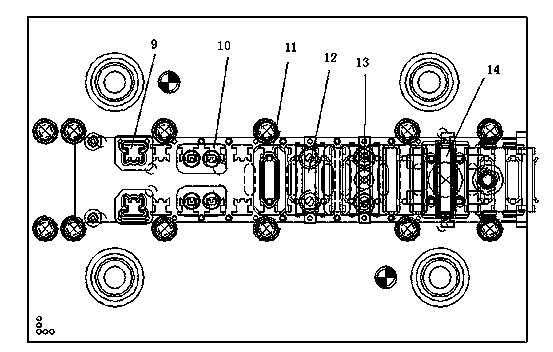

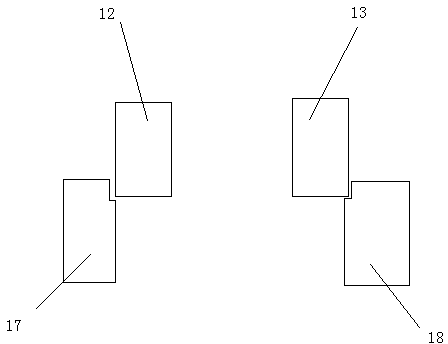

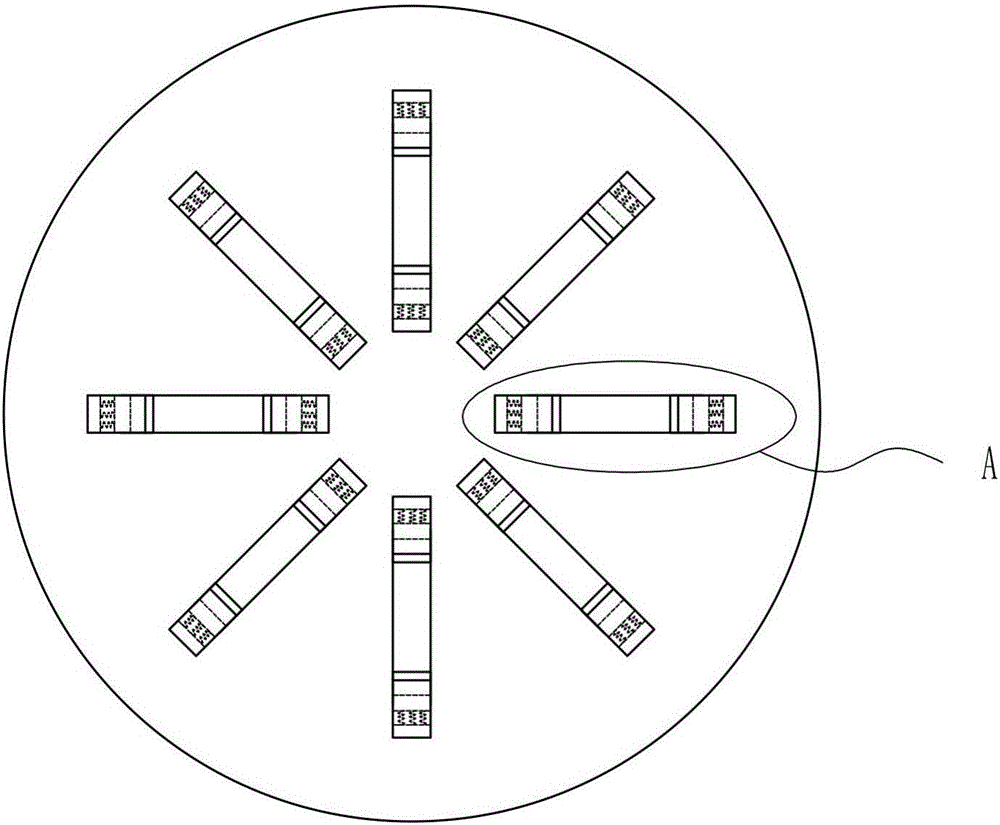

Continuous die capable of achieving intra-die riveting of laptop cooling fins

A continuous die capable of achieving intra-die riveting of laptop cooling fins comprises an upper die assembly and a lower die assembly. The upper die assembly comprises an upper die base, a backing plate and a male die fixing plate; the lower die assembly comprises a lower die base, a female die fixing plate and an unloading plate; a material strip is arranged between the upper die assembly and the lower die assembly; two male dies for cutting edges, two male dies for punching holes, two male dies for bending materials by 90 degrees and a male die for riveting are fixed to the male die fixing plate; two female dies for cutting edges, two female dies for punching holes, two female dies for bending materials by 90 degrees and a female die for riveting are fixed to the positions, corresponding to the male dies for stamping, of the female die fixing plate; an air cylinder is arranged on the male die fixing plate. According to the continuous die capable of achieving intra-die riveting of the laptop cooling fins, the number of the cooling fins to be riveted can be determined by adjusting parameters of the air cylinder, and labor cost is greatly reduced.

Owner:SUZHOU RISING CREATION PRECISION TOOLS

Nonmagnetic hard alloy and preparing method thereof

The present invention discloses a non-magnetic hard alloy and its preparation method. Said non-magnetic hard-alloy used wolfram carbide (WC) as main component, and is formed by adding Ni, Cr and Mo and its prparation method includes: bending material, wet grinding, filtering mixed slurry, drying and seiving, forming, vacuum sintering and checking. As compared with existent technology said invented product has the advantages of high hardness, good abrasive resistance, small friction coefficience, good polishing property, high compression strength and good rigidity, etc.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Trademark label and manufacturing method thereof

The invention relates to a trademark label and a manufacturing method thereof. The trademark label comprises a processing fabric, an upper part label template, a lower part trademark template, a metal film, a sealing sleeve fabric and a through hole, wherein a plurality of penetrating holes with sizes corresponding to the shape of trademarks are formed in positions corresponding to the trademarks on the processing fabric; the upper part of the processing fabric is provided with the upper part trademark template corresponding to the through hole; the lower part of the processing fabric is provided with the lower part trademark template corresponding to the through holes; a layer of metal film with the same size and form with the upper part trademark plate is compounded on the upper part trademark template; a layer of sealing cover fabric is pasted on the lower part trademark template. The manufacturing method of the trademark label comprises the following steps that an injection molding mold is processed; meanwhile, the fabrics are processed; shaping processing is performed; injection molding is started; the metal film is pasted. The trademark label and the manufacturing method provided by the invention have the advantages that the technical problem of difficulty in the technical level in aspects of cutting, grinding, polishing and the like of metal materials and the like in the prior art can be solved; in addition, when the products are installed, the trademarks are softer and lighter; the use and the installation are more convenient; the trademark label has good metal texture; the trade mark label is made of flexible and easy-to-bend materials, so that the installation is proper.

Owner:尹银爱

Preparation method of modified starch and PBS blending material

The invention discloses a preparation method of modified starch and PBS blending material. The preparation method comprises the following steps that starch and PBS are put into a vacuum drying oven with the temperature of 100-104 DEG C for drying for 6-7 hours so as to dry water; the starch, the PBS, [BMIM]Cl ionic liquid and magnesium chloride are put into a torque rheometer for melt blending, wherein the blending temperature is 110-120 DEG C, the rotating speed of a blending rotor is 65 r / min, and the blending time is 15-25 minutes; and a sample is prepared into a dumbbell type with the width of 4 mm by adopting a micro injection molding machine, wherein the injection pressure is 37-39 MPa, the injection temperature is 110-120 DEG C, the pressure maintaining pressure is 37-39 MPa, the temperature of a mold is 30-34 DEG C, the spacing of clamps is 41-43 mm, the stretching rate is 44-46 mm / min, and the bending material is obtained after cooling. The preparation method has the advantages of being simple and convenient, and easy to operate; and the prepared modified starch and the PBS blending material has good mechanical properties and can be prepared on a large scale.

Owner:太仓欧典新材料有限公司

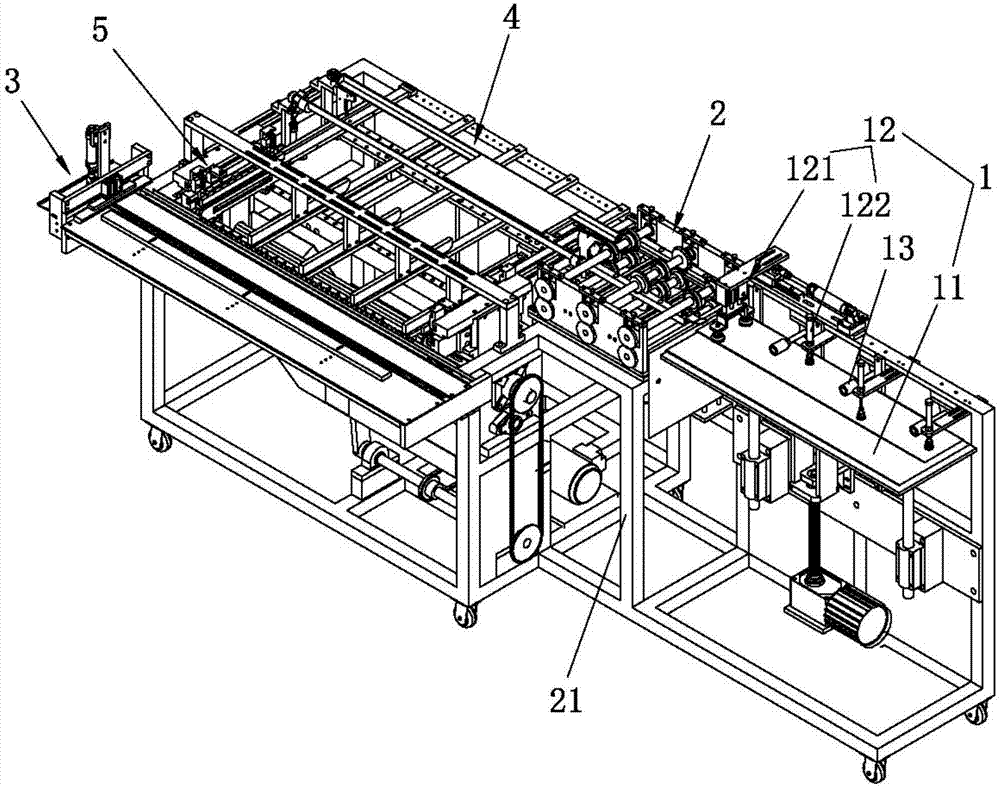

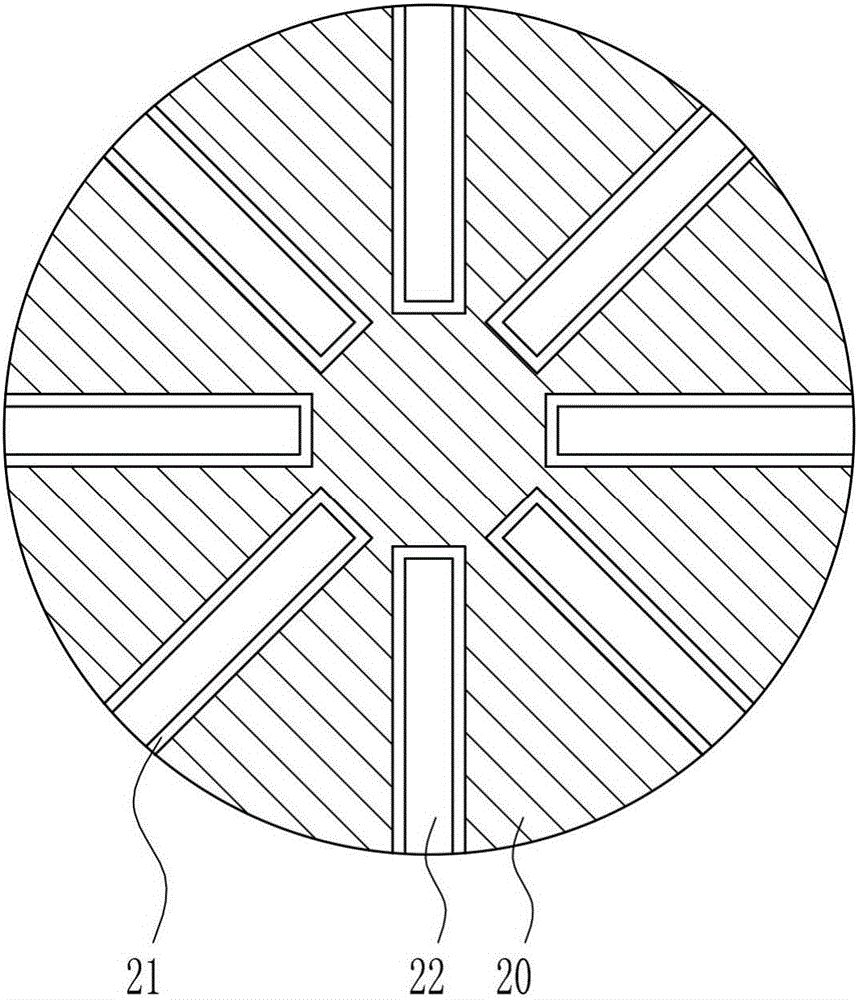

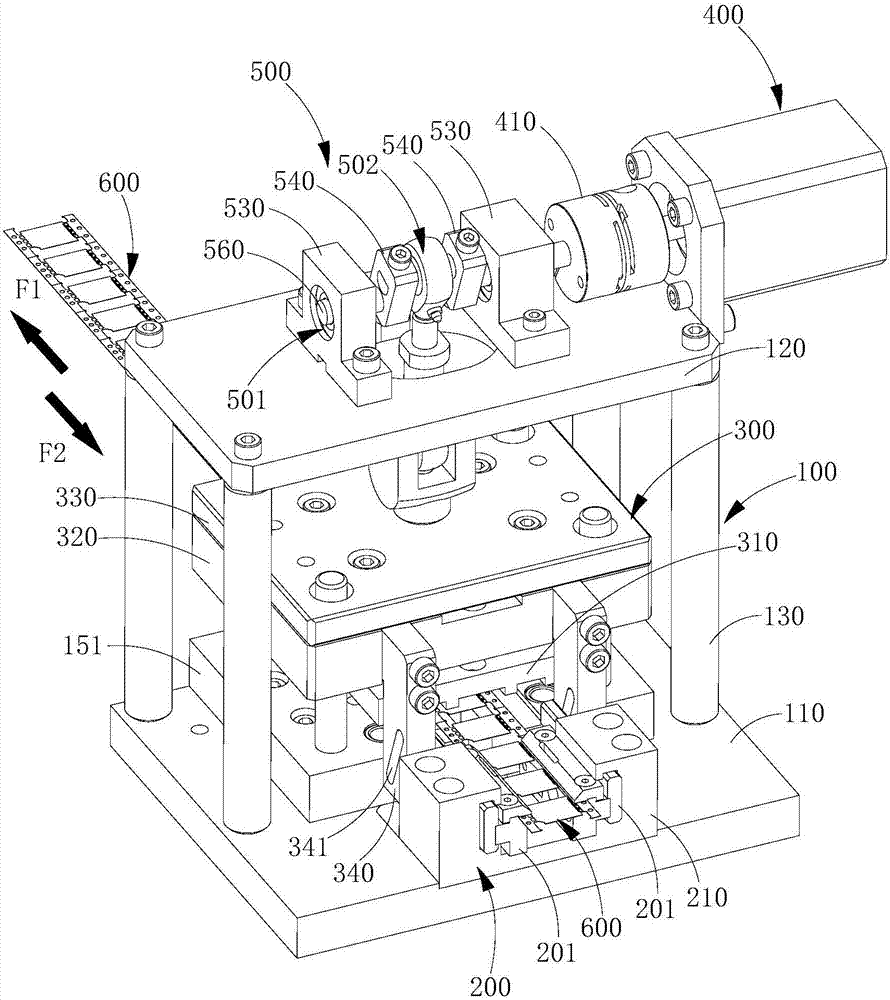

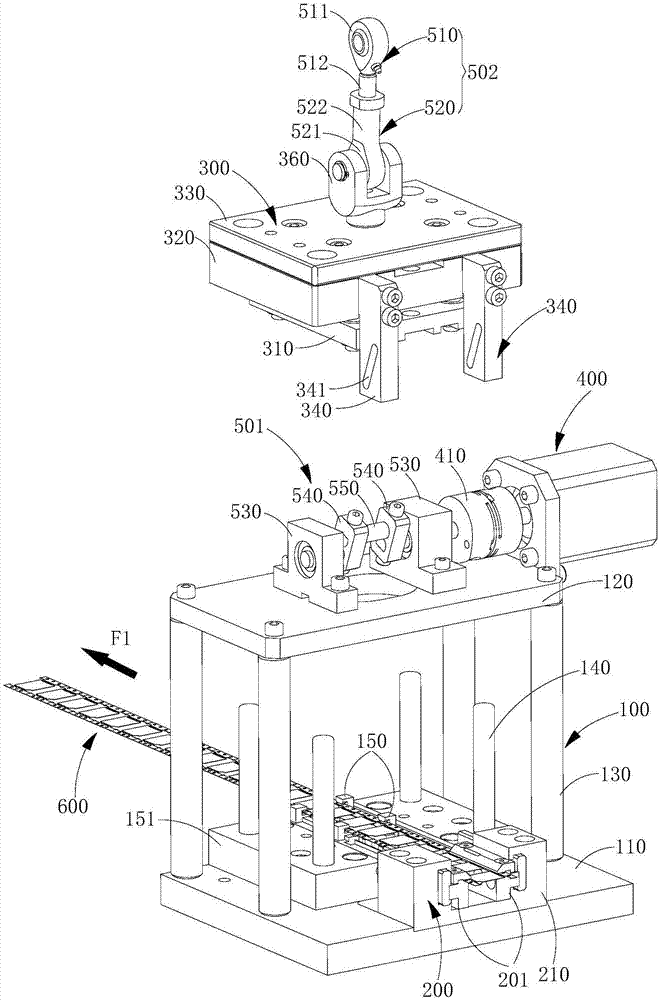

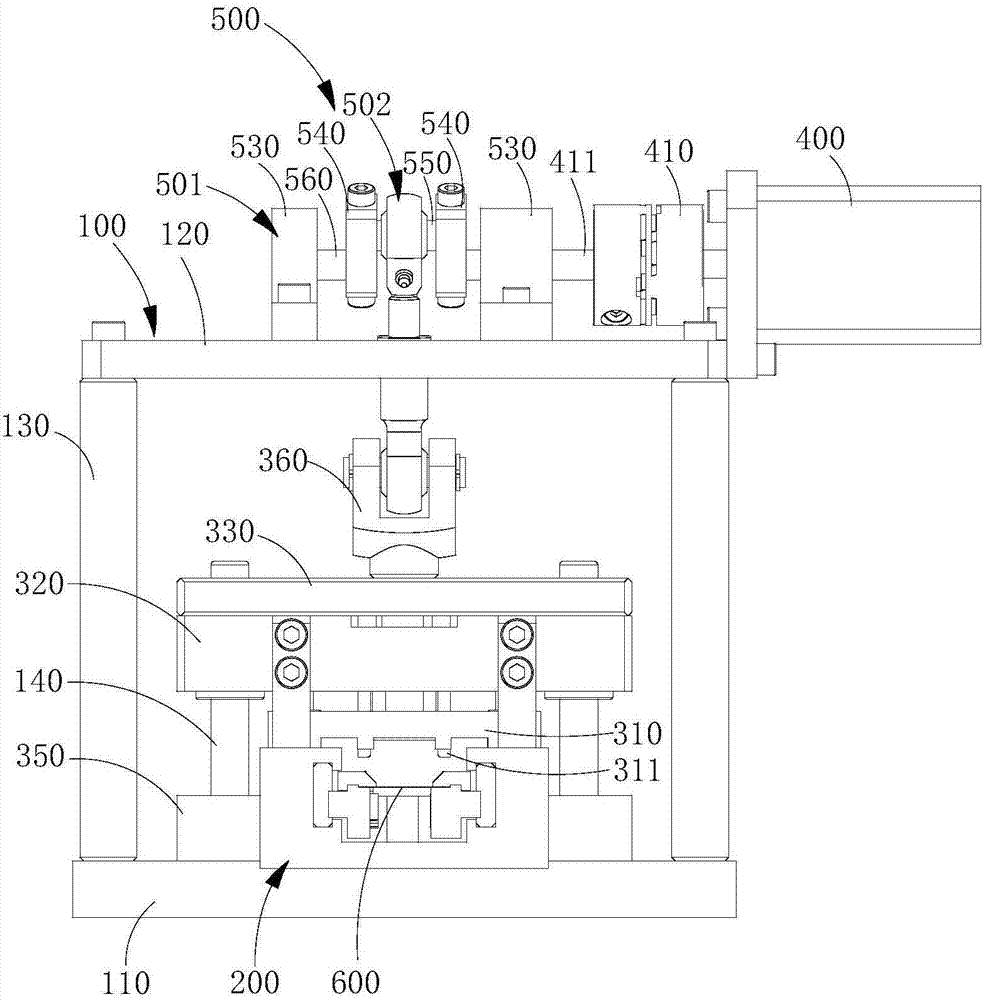

Automatic bending machine

PendingCN107952836AQuality improvementImprove bending efficiencyMetal-working feeding devicesPositioning devicesEngineeringMaterial supply

The invention relates to the technical field of bending equipment, in particular to an automatic bending machine. The automatic bending machine comprises a material supplying device for supplying materials, a pre-bending device used for pre-bending materials supplied by the material supplying device, and a body bending device for body bending of pre-bent materials; the pre-bending device comprisesa machine table, a material guiding assembly arranged on the machine table, a feeding mechanism used for driving the materials supplied by the material supplying device to move, and a pre-bending mechanism used for pre-bending the materials moved by the feeding mechanism; and the material guiding assembly is used for guiding the materials moved by the feeding mechanism. The automatic bending machine is simple in structure, automatically achieves feeding, pre-bending and body bending treatment of the plate materials, is high in automation degree, stable in work and good in plate material bending quality, improves the plate material bending efficiency, lowers the labor intensity of plate material bending, and reduces the production cost of plate material machining.

Owner:DONGGUAN TINSHINE TIN BOX

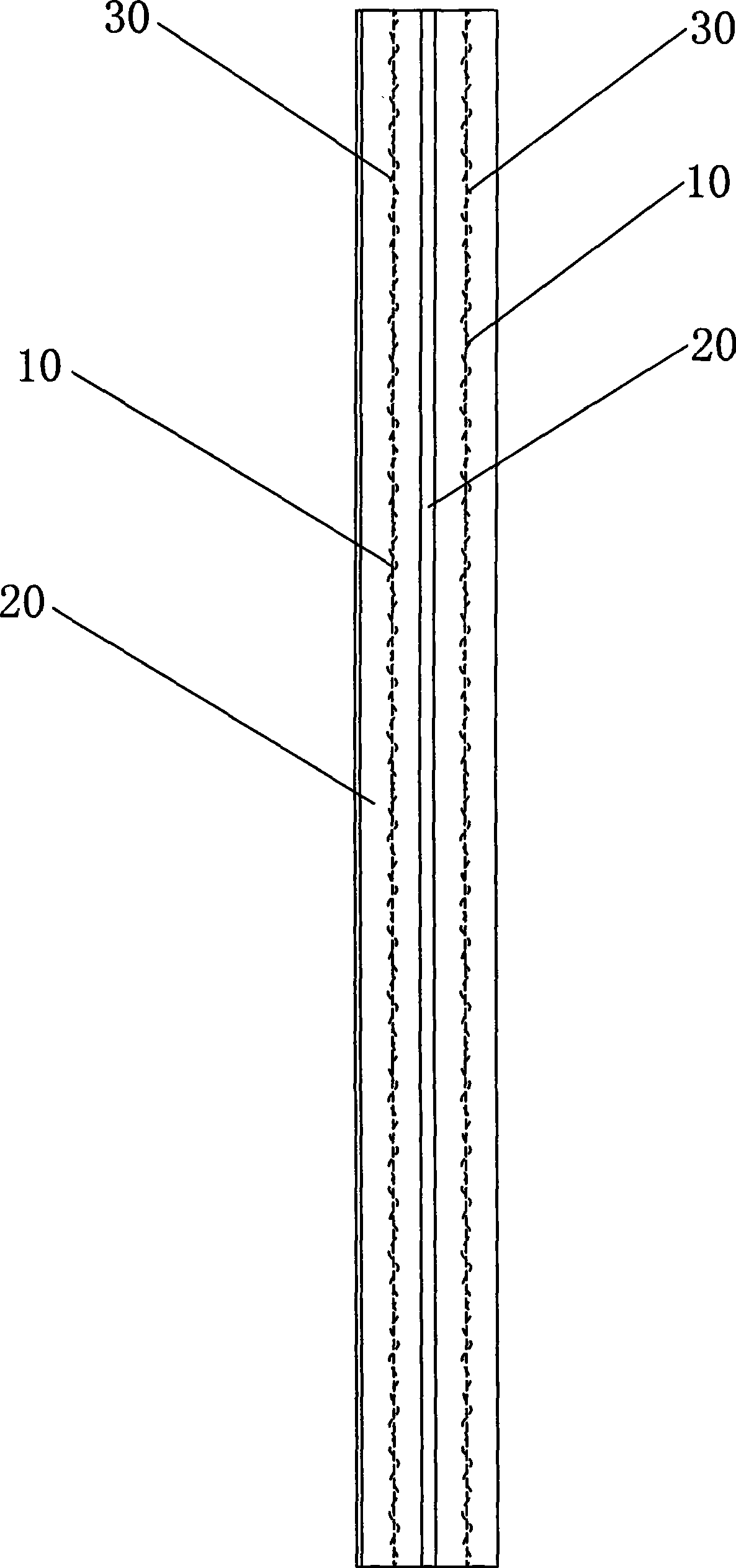

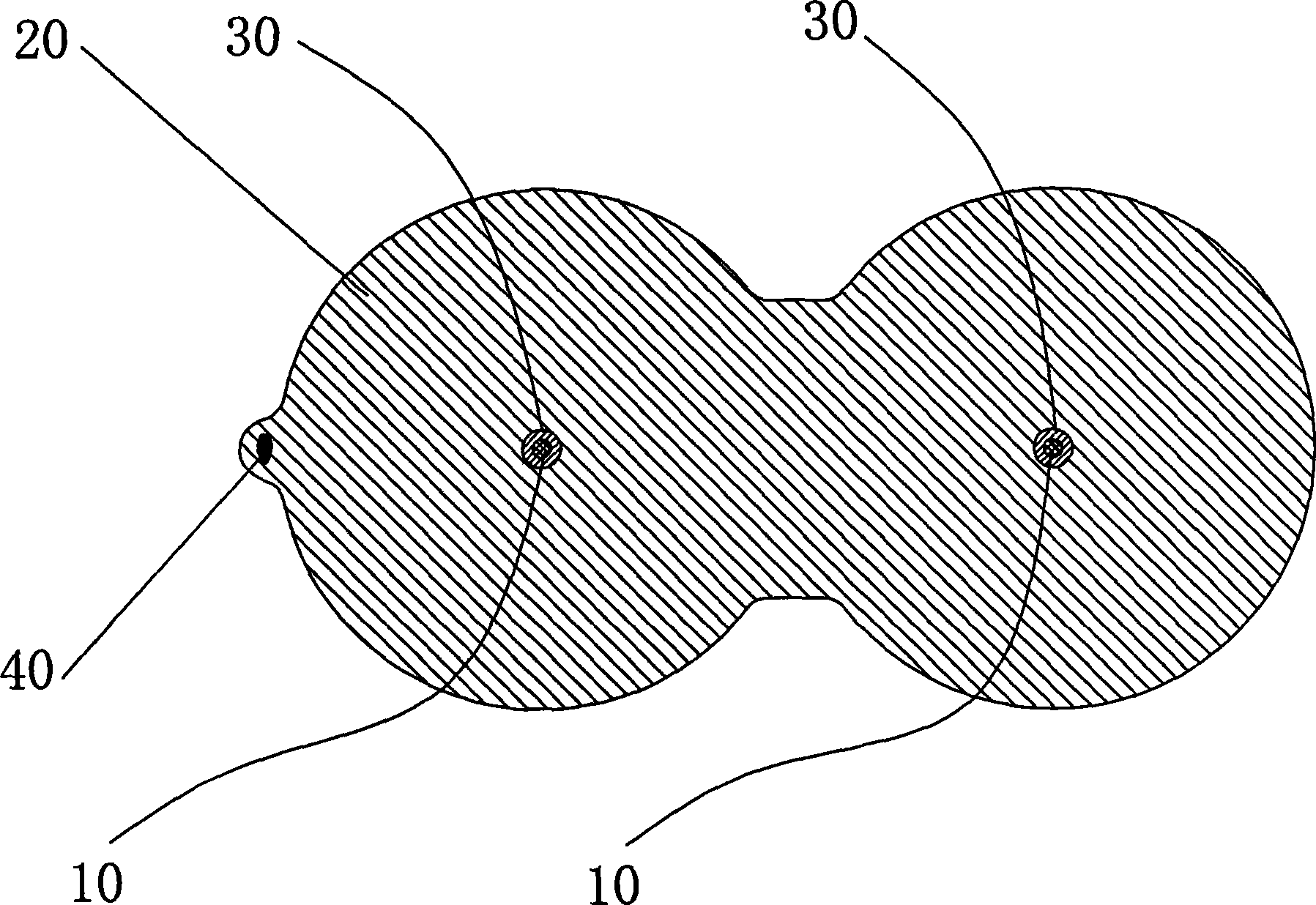

Anti-interference sound equipment line

InactiveCN101471156AResolve interferenceEasy to useInsulated cablesCircuit lead arrangements/reliefElectrical conductorInterference resistance

The invention relates to an audio cable, in particular to the audio cable which has good transmission signal effect and resists interference. The audio cable comprises a plurality of conductors formed by weaving fine brass wires and PVC protective layers packed outside the conductors, wherein an aluminum foil shielding layers are wound between the conductors and the PVC protective layers, the aluminum foil shielding layers are provided with the function of resisting external interference, prevent signals which are transmitted by the conductors from interference, and the aluminum foil shielding layers formed from winding has good effect of shielding interference and effect, wherein the thickness of aluminum foil is 0.025 mm. The audio cable has beneficial effects that firstly, solving the problem of the interference of a magnetic field, which is generated when a power source line and an audio line are arranged together, providing the audio cable which is beautiful and convenient for use, and has good transmission signals, secondly, solving the effect of inner loops of the audio cable and the external interference, the effects of shielding the electromagnetic interference and the effect are better, the aluminum foil shielding layer is quite compact, since the thickness of the aluminum foil shielding layer is thinner, the aluminum foil shielding layer is not easily broken during the process of bending materials.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

Fingertip pen/stylus

InactiveUS20010033765A1Prevent accidental markingWriting connectorsBrush bodiesPressure sensitiveEngineering

A multi-purpose fingertip pen / stylus comprising a flexible shaft having first and second ends made of a bendable material, which retains a twisted shape, said shaft sized of sufficient length to wrap and secure about the fingertip of a writing digit; the first end adapted as a stylus tip for use with pressure sensitive computer screens, and the second end adapted as a writing tip to extend sufficiently beyond the fingertip of the writing digit stylus to contact and write on a writing surface.

Owner:PRIME GLOBAL ENTERPRISES

Efficient bending device for wrench for hardware manufacturing

ActiveCN106311838AEasy to placeGuaranteed stable workMetal-working feeding devicesPositioning devicesEngineeringWrench

The invention relates to a bending device, in particular to an efficient bending device for a wrench for hardware manufacturing. In order to solve the technical problems, the invention provides the efficient bending device for the wrench for hardware manufacturing. The efficient bending device comprises a bottom plate, a collecting tank, transport units, a first slide rail, a first slide block, a top plate, a right bearing base, a nut, a lead screw, a left bearing base, a rotary motor, a first bracket, a second slide block, a second slide rail, first springs, a second swing rod, a fixed block, a first swing rod, a placing box, a bending table, second electromagnets, second springs, bending materials, iron placing plates, first electromagnets, a shaping slot and Z-shaped wood brackets; and the collecting tank is formed at the right side of the top of the bottom plate. The efficient bending device achieves the effect of high bending efficiency.

Owner:沈阳钢中宝科技有限公司

Blanking device

ActiveCN107186040APrecise processingImprove processing efficiencyMetal-working feeding devicesPositioning devicesMechanical engineeringBend Material

The invention relates a blanking device. The blanking device comprises a rack, a blanking mechanism, a feeding mechanism, a driving mechanism and a transmission mechanism, wherein the rack is provided with a support platform for supporting a material strap; the blanking mechanism is movably arranged on the rack, can ascend and descend relative to the rack and blanks and bends materials on the material strap on the support platform when descending; the feeding mechanism is arranged on the rack and linked with the blanking mechanism; and the driving mechanism is arranged on the tack, the transmission mechanism is connected between the driving mechanism and the blanking mechanism, the driving mechanism drives the blanking mechanism to ascend and descend through the transmission mechanism, and the feeding mechanism is driven to clamp and drive the material strap to move forwards when the blanking mechanism ascends, so that the blanking mechanism can continually blank and bend the materials on the material strap. According to the blanking device, the blanking mechanism and the feeding mechanism are linked and share the same power source, and the blanking device is accurate in processing and high in processing efficiency.

Owner:GUANGDONG EVERWIN PRECISION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com