Automatic heating mechanism

A heating device and heating furnace technology, which is applied to operating devices, lighting and heating equipment, forging/pressing/hammer devices, etc., can solve problems such as long blank time, clogging of heating furnaces, equipment failures, etc., to reduce abnormal heating jams material, preventing excessive bending, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail as follows.

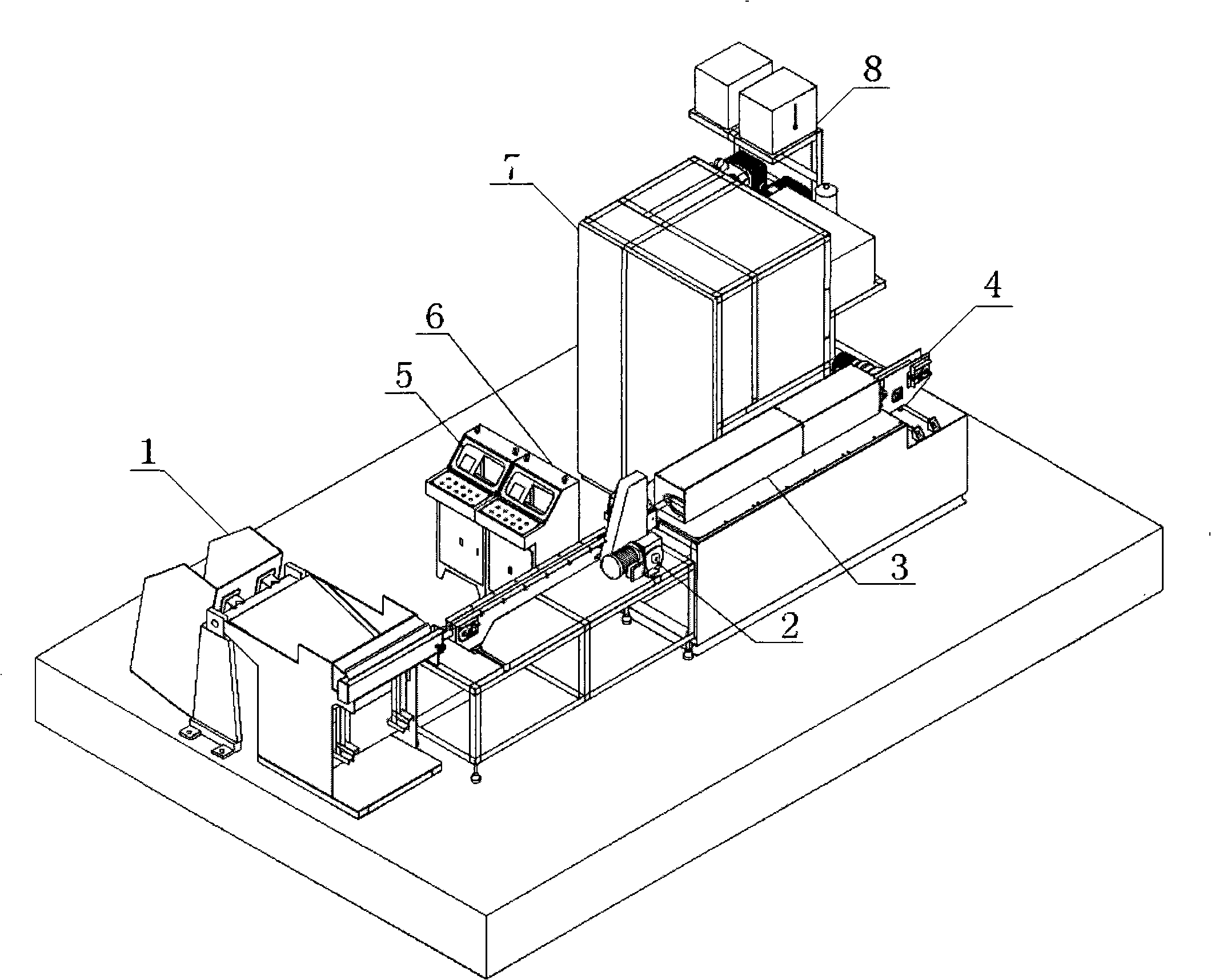

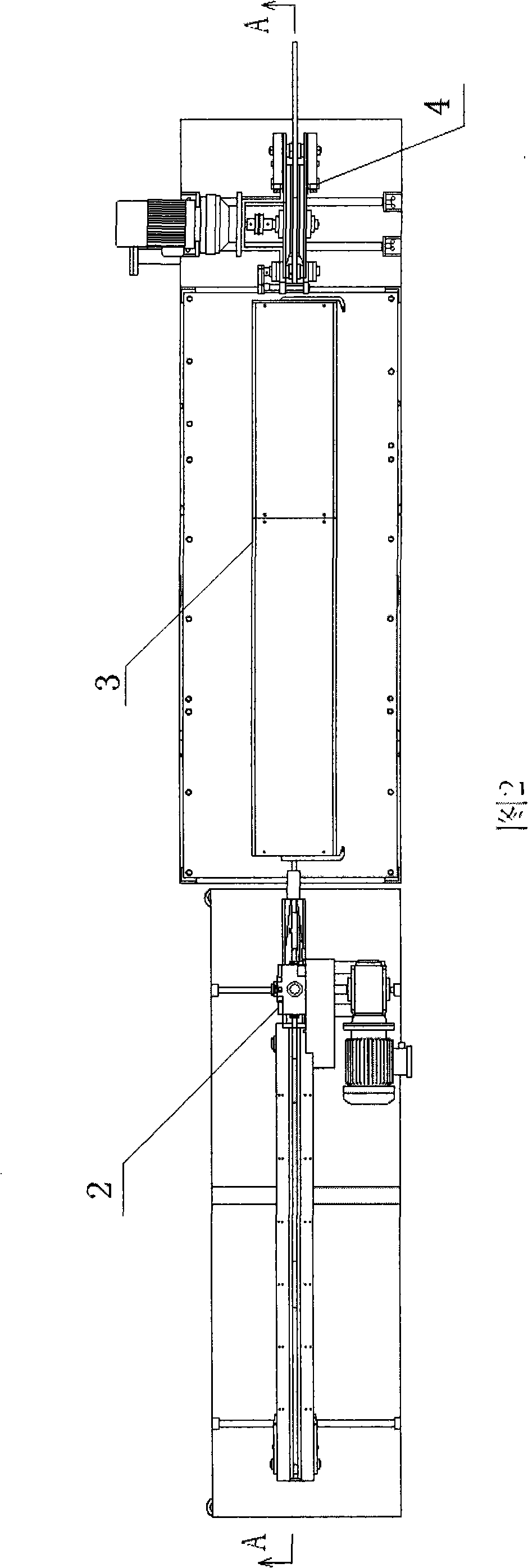

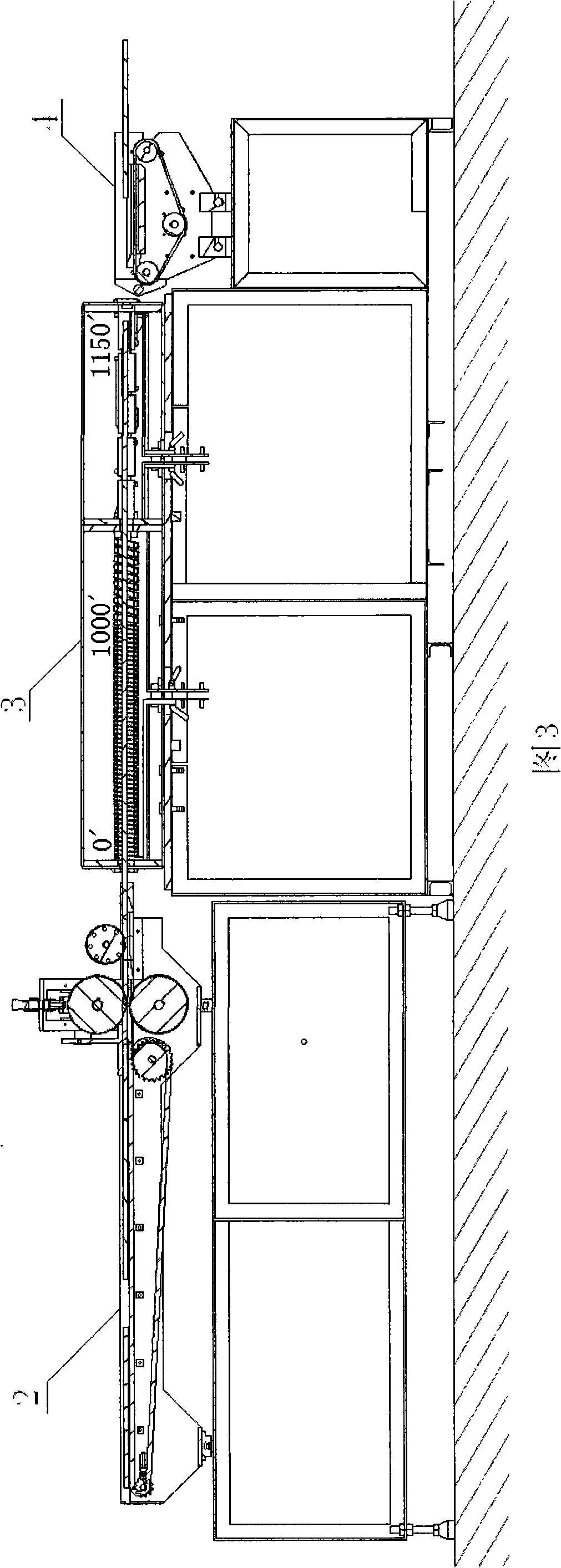

[0025] figure 1 It is the overall structure diagram of the automatic heating device of the present invention; Fig. 2 is the top view of the roller feeder, the heating furnace body and the quick discharge machine part in the present invention; Fig. 3 is the A-A sectional view of Fig. 2; Fig. 4 is the present invention The structure schematic diagram of the roller feeder in; Fig. 5 is the structure schematic diagram of the heating furnace body in the present invention.

[0026] As shown in the figure, the automatic heating device of the present invention consists of eight major parts, namely: step feeder 1, roller feeder 2, feeding equipment operation box 6, induction heating furnace body 3, heating furnace operation box 5, heating furnace Power box 7, plate heat exchanger group 8, quick discharge machine 4.

[0027] The coordination between the equipment is assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com