Photo-induced bending conductive actuator and manufacturing method thereof

A photobending and actuator technology, applied in the field of bionics, can solve the problems such as failure to integrate and miniaturize photobend actuators or robots, and no conductive actuators based on photobend polymer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

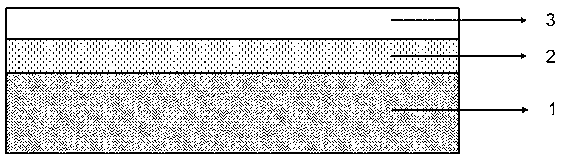

[0094] Such as figure 1 As shown, the photobending actuator 1 of the substrate is a multiphase liquid crystal, the adhesive layer 2 adopts an adhesive that requires double curing, and the conductive layer 3 is carbon nanotubes, and the thickness of the conductive layer is 200 nm. The entire device structure is described as:

[0095] Multiphase Liquid Crystals / Dual Curing Adhesives / Carbon Nanotubes

[0096] The preparation method is as follows:

[0097] ① Use acetone, ethanol solution and deionized water to ultrasonically clean the surface of the glass substrate with a surface roughness less than 1 nm, and dry it with dry nitrogen after cleaning;

[0098] ② The conductive layer of carbon nanotubes was prepared by spin-coating. The spin-coating speed was 1000 rpm, the duration was 30 s, the film thickness was about 200 nm, and then the substrate was thermally annealed at 130 °C;

[0099] ③ Spin-coating on the carbon nanotube layer requires a double-cured adhesive, and the adh...

Embodiment 2

[0113] Such as figure 1 As shown, the photobending actuator 1 of the substrate is liquid crystal gel, the adhesive layer 2 adopts an adhesive that requires double curing, and the conductive layer 3 is silver nanowires, and the thickness of the conductive layer is 180 nm. The entire device structure is described as:

[0114] Liquid crystal gel / dual curing adhesive / silver nanowire

[0115] Described adhesive raw material comprises following components:

[0116] Unsaturated polyester resin (free radical UV curing agent) 30~40 parts

[0117] Epoxy resin (heat curing agent) 35~45 parts

[0118] Multifunctional acrylic acid (thinner) 0.2~3 parts

[0119] Photoinitiator 0.1~3 parts

[0120] Photosensitizer and auxiliary agent 0.2~6 parts.

[0121] The preparation method is similar to Example 1.

Embodiment 3

[0123] Such as figure 1 As shown, the photobending actuator 1 of the substrate is a liquid crystal elastomer, the adhesive layer 2 is an adhesive that requires double curing, and the conductive layer 3 is a gold nanowire, and the thickness of the conductive layer is 160 nm. The entire device structure is described as:

[0124] Liquid crystal elastomer / dual-cured adhesive / gold nanowires

[0125] Described adhesive raw material comprises following components:

[0126] Epoxy resin (cationic UV curing agent) 35~45 parts

[0127] Amino resin (heat curing agent) 40~45 parts

[0128] Thinner (vinyl ether monomer) 4.0~9 parts

[0129] Cationic photoinitiator (aromatic iodonium salt) 1.2~3 parts

[0130] Photosensitizer and auxiliary agent 0.2~3 parts.

[0131] The preparation method is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com