Pipe bending machine

A pipe bending machine and pipe bending technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as large operating errors, affecting work efficiency, wasting manpower, etc., to reduce production costs, improve work efficiency, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

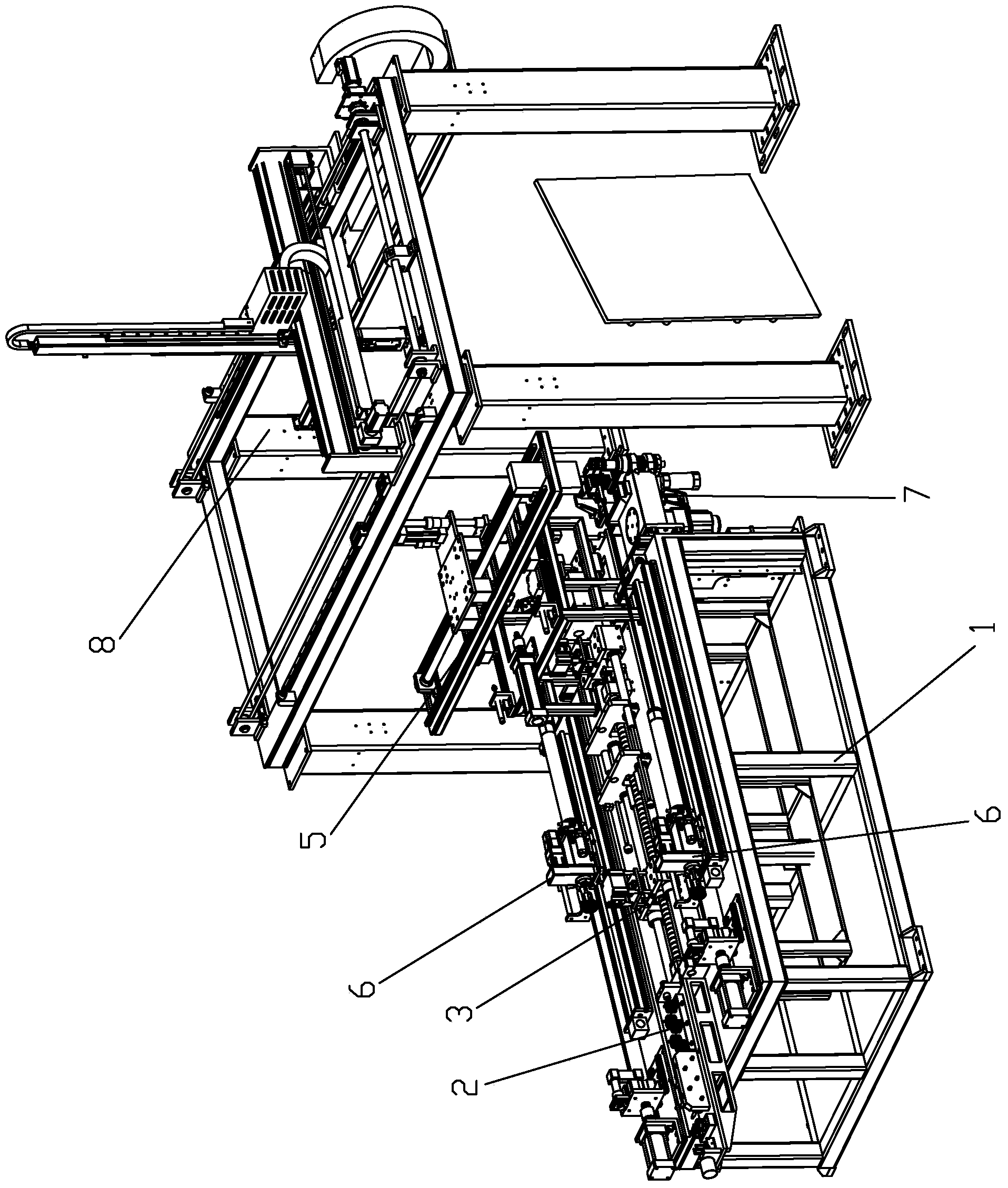

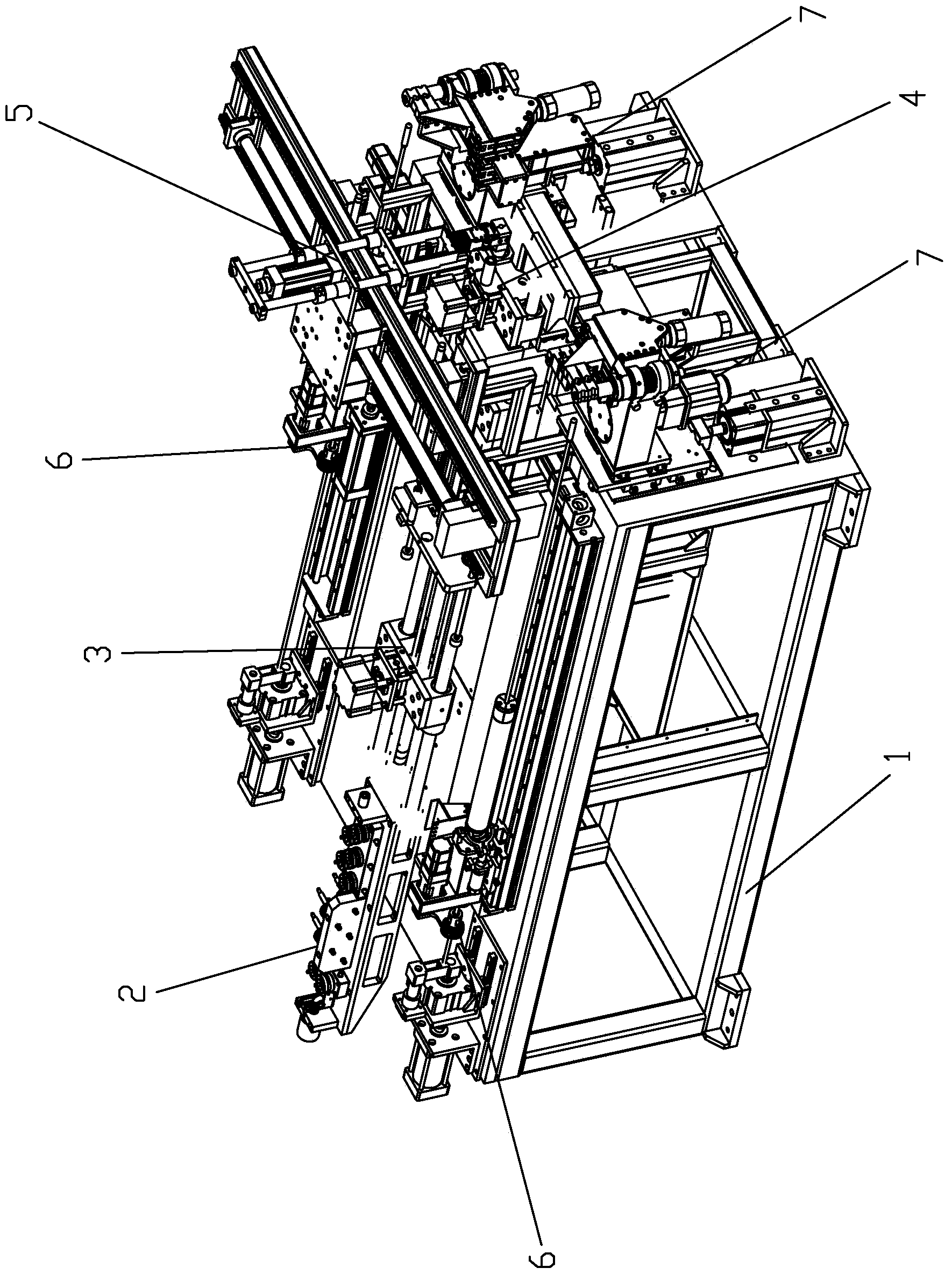

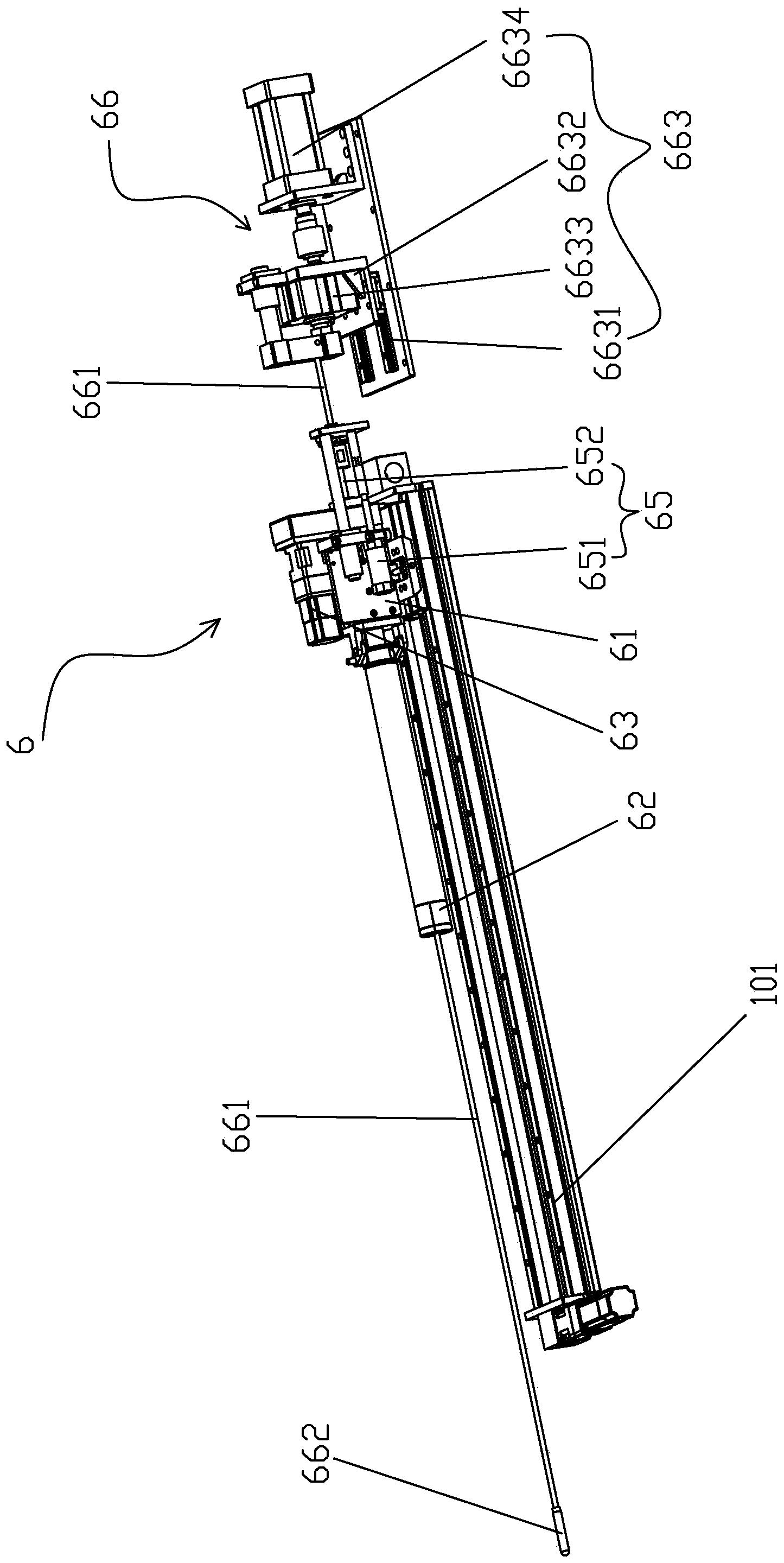

[0042] Such as Figure 1 to Figure 5 As shown, a pipe bending machine includes a frame 1, the frame 1 is provided with a straightening mechanism 2 capable of straightening the material tube, and the output end of the straightening mechanism 2 is provided with a feeding mechanism 3 , the output end of the described feeding mechanism 3 is provided with a material opening mechanism 4, the output end of the described material opening mechanism 4 is provided with a material shifting mechanism 5, and the described material moving mechanism 5 can move the described material opening mechanism 4 The cut material pipe is transferred to the elbow feeding mechanism 6 located next to the feeding mechanism 3, and the output end of the elbow feeding mechanism 6 is provided with a bending material that can bend the material pipe it sends. Mechanism 7, the output end of the material bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com